A metal-doped tin oxide transparent dispersion and its preparation method

A technology of metal doping and tin oxide, applied in the field of dispersions, can solve the problems of poor particle conductivity and unreported preparation methods of dispersions, and achieve the effects of improving dispersibility, low price and easy availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

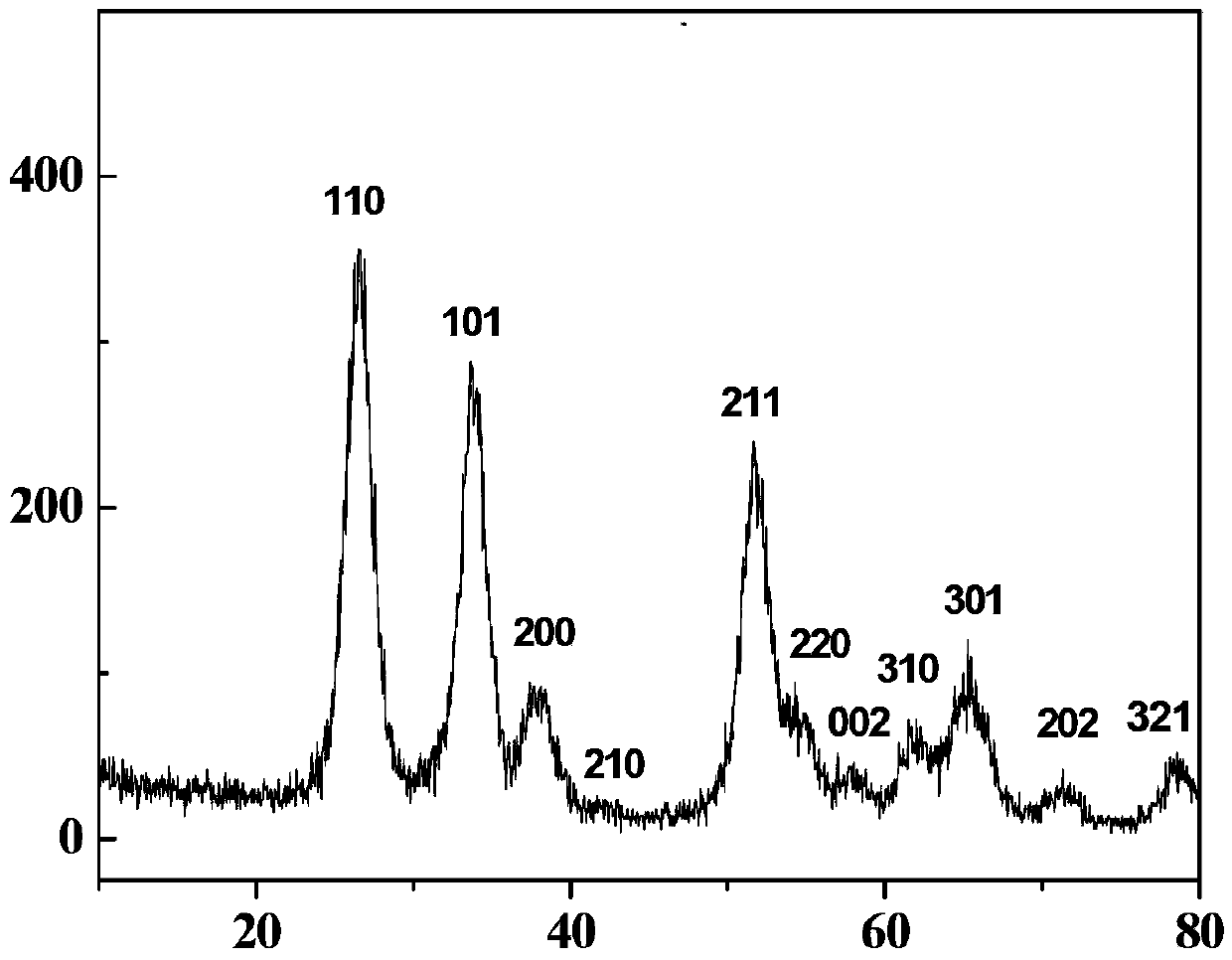

Image

Examples

Embodiment 1

[0040] A method for preparing a metal-doped tin oxide transparent dispersion, comprising the steps of:

[0041] 1) Weigh 35.06g SnCl 4 ·5H 2 O, 1.85gMgCl 2 ·5H 2 O and 2.16gMnCl 2 4H 2 O, being dissolved in 100mL mass fraction of 3.5wt% hydrochloric acid, dropwise adding 3mol / L ammonia solution to the pH value of the system to 3 in the mixed metal salt solution, to obtain hydroxide precipitation;

[0042] 2) Disperse the generated hydroxide in ethanol, add 2.62g of sodium lauryl sulfate dropwise, control the temperature at 70°C, and reflux for 8 hours to obtain the precipitate of hydroxide coated with modifier;

[0043] 3) Transfer the precipitated hydroxide of the coating modifier to the reaction kettle, the weight ratio of the hydroxide of the coating modifier to water is 10:100; The heated product was washed several times with distilled water and ethanol until no chloride ions were detected to obtain the hydrothermal reaction product;

[0044] 4) Disperse the hydroth...

Embodiment 2

[0047] A method for preparing a metal-doped tin oxide transparent dispersion, comprising the steps of:

[0048] 1) Weigh 24.87gSn(NO 3 ) 2 · and 2.28g of Sb(NO 3 ) 3 , be dissolved in 100mL of nitric acid with a mass fraction of 3.5wt%, and dropwise add 3mol / L ammonia solution to the mixed metal salt solution until the pH of the system is 3 to obtain hydroxide precipitation;

[0049] 2) Disperse the generated hydroxide in n-propanol, add 1.31g of γ-(methacryloyloxy)propyltrimethoxysilane dropwise, control the temperature at 100°C, and reflux for 4 hours to obtain coating modification Precipitation of the hydroxide of the agent.

[0050] 3) Then disperse the precipitated hydroxide of the coating modifier into distilled water, and transfer it to the reaction kettle. The weight ratio of the hydroxide of the coating modifier to water is 30:100; 220°C hydrothermal After 5 hours, the hydrothermal product was washed several times with distilled water and ethanol until no chlorid...

Embodiment 3

[0054] A method for preparing a metal-doped tin oxide transparent dispersion, comprising the steps of:

[0055] 1) Weigh 21.47gSnSO 4 and 1.61gZnSO 4 , dissolved in 100mL of sulfuric acid with a mass fraction of 3.5wt%, and dropwise adding 3mol / L sodium hydroxide solution to the mixed metal salt solution until the pH of the system is 4 to obtain hydroxide precipitation;

[0056] 2) Disperse the generated hydroxide in n-hexane, add 1.31 g of octadecylamine dropwise, control the temperature at 120°C, and reflux for 6 hours to obtain the precipitate of hydroxide coated with modifier.

[0057] 3) Then disperse the precipitated hydroxide of the coated modifier into distilled water and transfer it to the reaction kettle. The weight ratio of the hydroxide of the coated modifier to water is 50:100; 180°C hydrothermal After 10 hours, the hydrothermal product was washed several times with distilled water and ethanol until no chloride ions were detected to obtain the hydrothermal react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com