Art spraying device and spraying process thereof

A sprayer, art technology, applied in the field of art sprayer and its spraying process, can solve the problems of inconvenient cleaning, inconvenience, complex structure, etc., to improve speed and uniformity, good social and economic benefits, and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

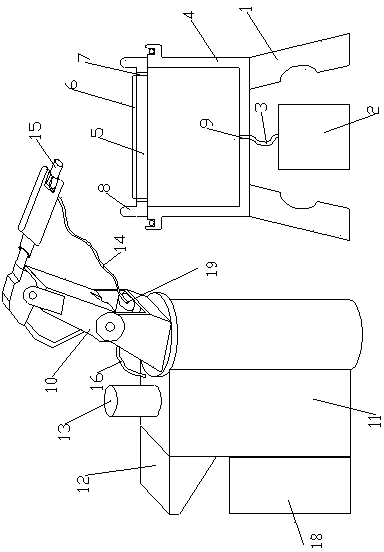

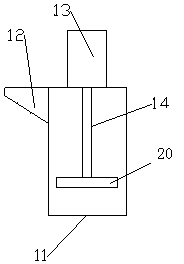

[0016] Embodiment 1: as figure 1 , 2 , shown in 3, a kind of art sprayer, comprises support 1, and described support 1 is fixedly installed with receiving trough 4, and the top of receiving trough 4 is movably installed with support plate 5, and is movably installed above support plate 5 There is a work surface 6, and the support plates 5 on both sides of the work surface 6 are provided with leakage holes 7, the leakage holes 7 communicate with the material receiving tank 4, and the bottom of the material receiving tank 4 is provided with a discharge port 9, and the material discharge The bottom of the port 9 is provided with a material receiving hose 3, and the lower part of the material receiving hose 3 is provided with a material receiving cylinder 2, and a mechanical arm 10 is fixedly installed above one side of the material receiving tank 4, and one side of the mechanical arm 10 is fixedly installed. There is a batching bucket 11, a stirring motor 13 is arranged above th...

Embodiment 2

[0019] Embodiment 2: as figure 1 , 2, shown in 3, a kind of art sprayer, comprises support 1, and described support 1 is fixedly installed with receiving trough 4, and the top of receiving trough 4 is movably installed with support plate 5, and is movably installed above support plate 5 There is a work surface 6, and the support plates 5 on both sides of the work surface 6 are provided with leakage holes 7, the leakage holes 7 communicate with the material receiving tank 4, and the bottom of the material receiving tank 4 is provided with a discharge port 9, and the material discharge The bottom of the port 9 is provided with a material receiving hose 3, and the lower part of the material receiving hose 3 is provided with a material receiving cylinder 2, and a mechanical arm 10 is fixedly installed above one side of the material receiving tank 4, and one side of the mechanical arm 10 is fixedly installed. There is a batching bucket 11, a stirring motor 13 is arranged above the...

Embodiment 3

[0022] Embodiment 3: as figure 1 , 2 , shown in 3, a kind of art sprayer, comprises support 1, and described support 1 is fixedly installed with receiving trough 4, and the top of receiving trough 4 is movably installed with support plate 5, and is movably installed above support plate 5 There is a work surface 6, and the support plates 5 on both sides of the work surface 6 are provided with leakage holes 7, the leakage holes 7 communicate with the material receiving tank 4, and the bottom of the material receiving tank 4 is provided with a discharge port 9, and the material discharge The bottom of the port 9 is provided with a material receiving hose 3, and the lower part of the material receiving hose 3 is provided with a material receiving cylinder 2, and a mechanical arm 10 is fixedly installed above one side of the material receiving tank 4, and one side of the mechanical arm 10 is fixedly installed. There is a batching bucket 11, a stirring motor 13 is arranged above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com