Equipment and method for solid/liquid composite continuous casting of coating materials

A coating material and forming equipment technology, applied in the field of coating material solid/liquid composite continuous casting and forming equipment, can solve the problems of high production cost, complex equipment, many supporting facilities, etc., to achieve convenient operation and maintenance, safe and reliable use , the layout is reasonable and compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

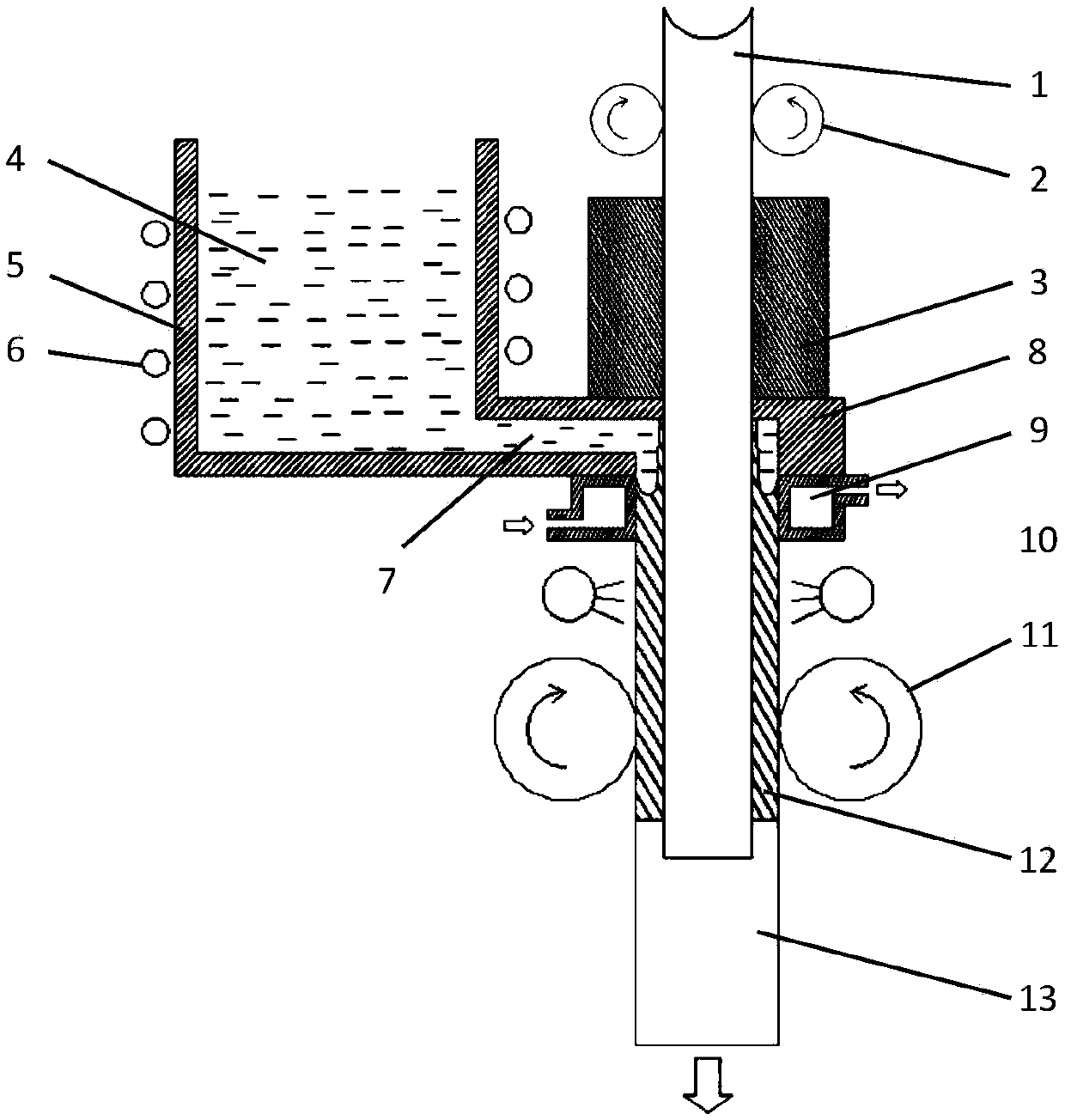

[0038] The core material is a Q235 steel bar with a diameter of 15 mm, and a copper-clad steel composite bar with a thickness of 1 mm of pure copper in the cladding layer is formed by continuous casting.

[0039] Under air conditions, the heater (6) heats and insulates the cladding pure copper melt in the crucible (5) to 1200°C; during the continuous casting process, it is continuously filled into the core material protection device (3). Nitrogen; start the traction mechanism (11), so that the Q235 steel bar starts to move towards the dummy ingot through the core material guiding and positioning device (2) and the core material protection device (3), and at the same time, the side of the head end of the dummy bar (13) leaves position of the draft tube (7); then the cladding pure copper melt in the crucible (5) flows into the draft tube (7) from the bottom side of the crucible (5) into the reverse solidifier (9), and passes through the high-temperature cladding The contact betw...

Embodiment 2

[0041] The core material is a pure copper wire with a diameter of 2mm, and a silver-clad copper composite wire with a cladding layer of pure silver with a thickness of 0.2mm is formed by continuous casting.

[0042] Under the condition of argon gas protection, the clad pure silver melt in the crucible (5) is heated and kept warm to 1050°C by the heater (6); Fill in argon; start the traction mechanism (11), so that the core material pure copper wire passes through the core material guide and positioning device (2) and the core material protection device (3) and starts to move towards the direction of the dummy ingot, and at the same time the dummy rod (13) The side of the head end leaves the position of the draft tube (7); then the coated pure silver melt in the crucible (5) flows from the bottom side of the crucible (5) into the draft tube (7) and enters the reverse coagulator (9), Through the contact between the high-temperature clad pure silver melt and the unpreheated pure ...

Embodiment 3

[0044] The core material is a pure titanium pipe with a diameter of 6 mm and a wall thickness of 1 mm, and a copper-clad titanium composite pipe with a cladding layer of pure copper with a thickness of 1 mm.

[0045] Under the condition of argon gas protection, the cladding layer pure copper melt in the crucible (5) is heated and kept warm to 1150°C by the heater (6); during the continuous casting process, the core material protection device (3) and The pure titanium pipe is continuously filled with argon gas; the traction mechanism (11) is started, so that the core material pure titanium pipe passes through the core material guiding and positioning device (2) and the core material protection device (3) and begins to move toward the dummy The side of the head end of the ingot rod (13) leaves the position of the guide tube (7); then the clad pure copper melt in the crucible (5) flows from the bottom side of the crucible (5) into the guide tube (7) and enters the reverse solidifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com