Preparation method of hollow polyimide fiber membrane applied to sulfide adsorption

A polyimide, fiber membrane technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve problems such as no adsorption effect of sulfides, no reports yet, and achieve cost Low cost, simple operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

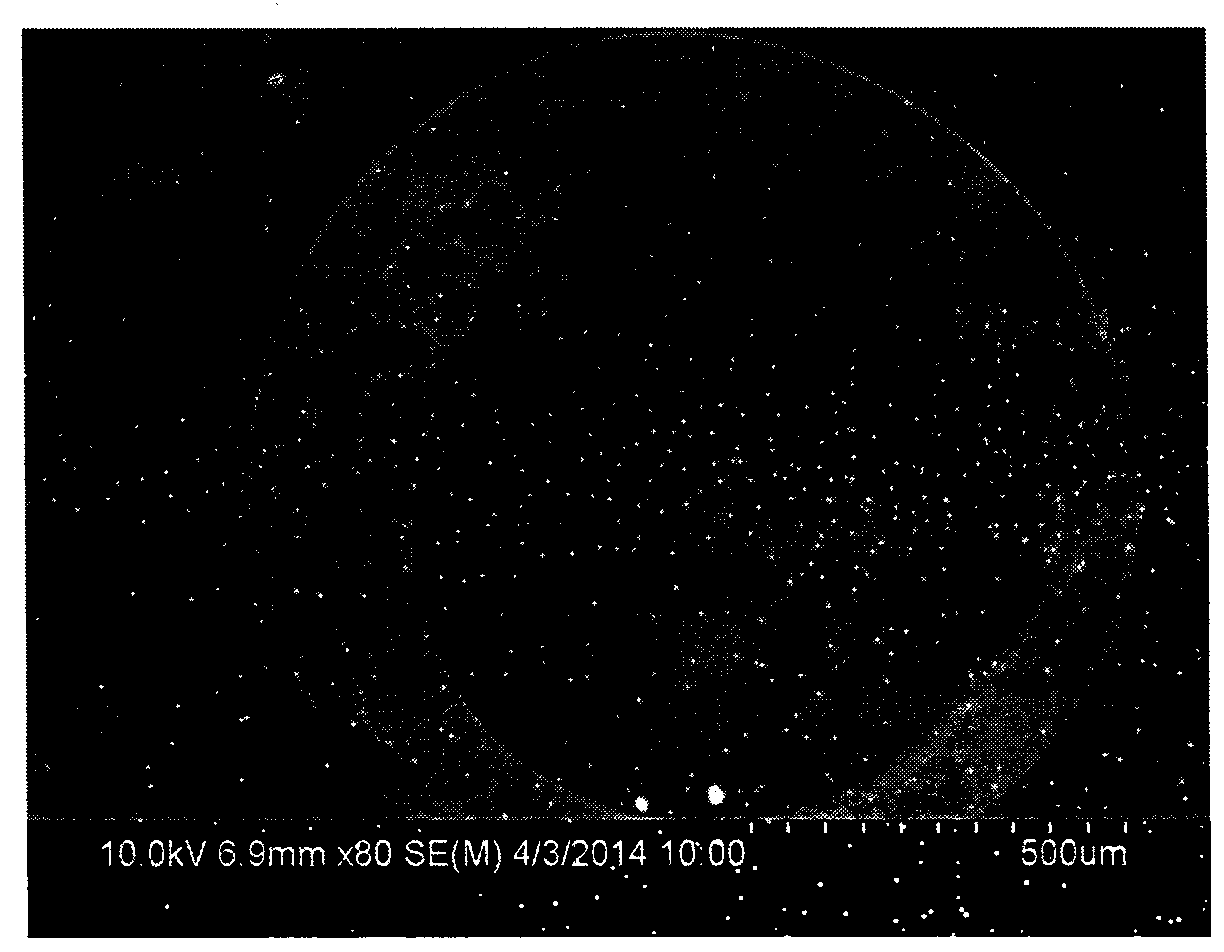

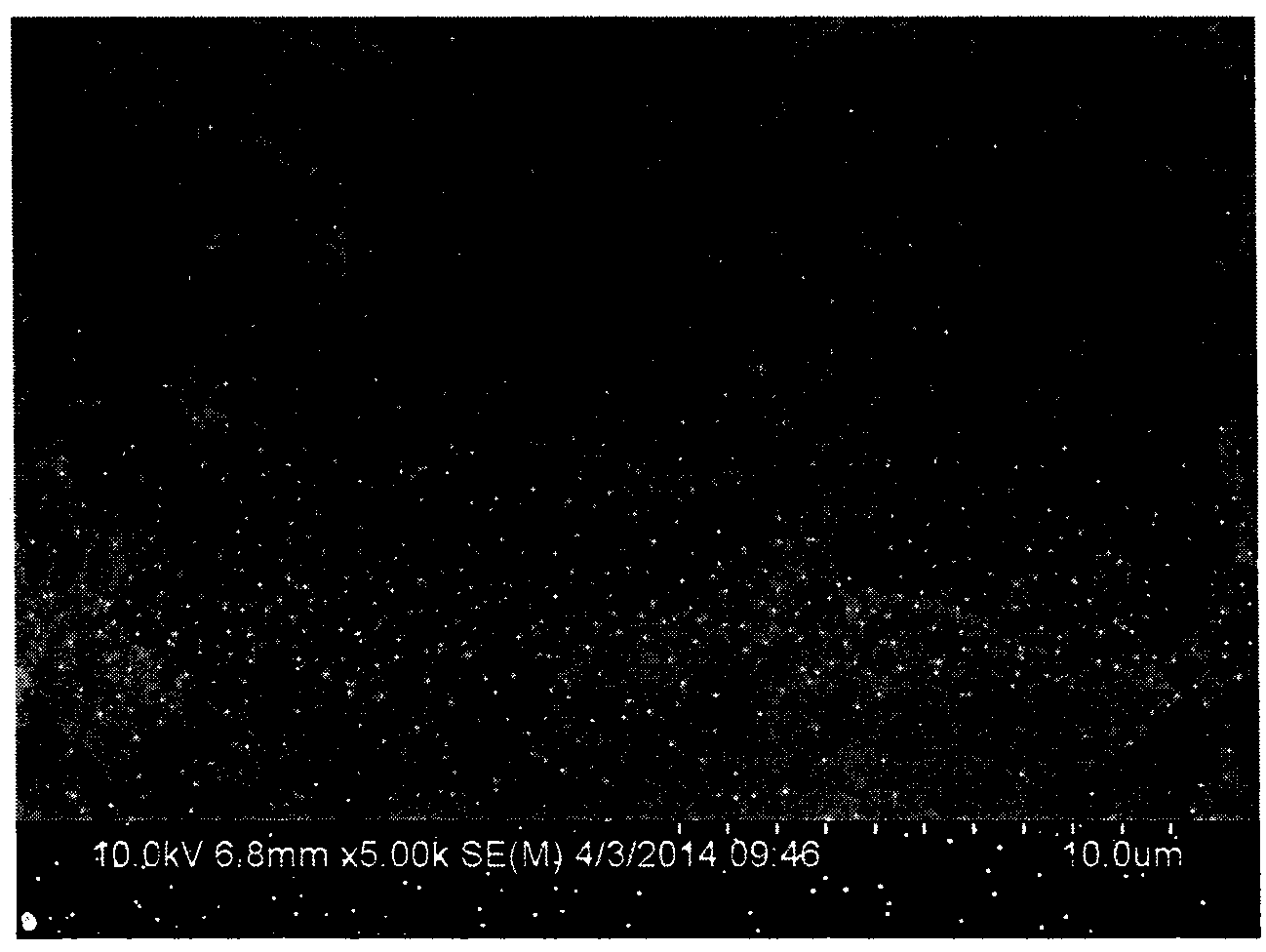

Image

Examples

Embodiment 1

[0019] (1) Preparation of spinning dope:

[0020] The polyimide matrix material was synthesized from two monomers, pyromellitic dianhydride and 4,4'-diaminodiphenyl ether. Before synthesis, the two monomer raw materials of pyromellitic dianhydride and 4,4'-diaminodiphenyl ether were put into a vacuum drying oven at 120°C for 24 hours, and the solvent N-methylpyrrolidone was removed with activated 3A molecular sieves. Water treatment, the treatment time is more than 24 hours. Take the dried 4,4'-diaminodiphenyl ether (6.01g, 30mmol) and dissolve it in N-methylpyrrolidone (69ml). After the 4,4'-diaminodiphenyl ether is completely dissolved, add Tetracarboxylic dianhydride (6.54 g, 30 mmol). After stirring and reacting at room temperature for 4 hours, a polyamic acid solution with a concentration of 15% by mass was obtained. Then add 9.3g of AgY molecular sieve, the mass percentage of molecular sieve is 10%, fully stir for more than 4 hours, and finally go through vacuum defoa...

Embodiment 2

[0026] (1) Preparation of spinning dope:

[0027] The polyimide matrix material was synthesized from two monomers, pyromellitic dianhydride and 4,4'-diaminodiphenyl ether. Before synthesis, the two monomer raw materials of pyromellitic dianhydride and 4,4'-diaminodiphenyl ether were put into a vacuum drying oven at 120°C for 24 hours, and the solvent N-methylpyrrolidone was removed with activated 3A molecular sieves. Water treatment, the treatment time is more than 24 hours. Take the dried 4,4'-diaminodiphenyl ether (6.01g, 30mmol) and dissolve it in N-methylpyrrolidone (49ml). After the 4,4'-diaminodiphenyl ether is completely dissolved, add Tetraformic dianhydride (6.54g, 30mmol) (note: add in several times, at least 3 times, to ensure full reaction of the monomer). After stirring and reacting at room temperature for 4 hours, a polyamic acid solution with a concentration of 20% by mass was obtained. Afterwards, 11.1 g of AgY molecular sieves were added, the mass percentag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com