Reversing motor

A technology of a motor and a cover, applied in the field of motors, can solve the problems of waste of motor power and easy heating of the motor, and achieve the effects of enhanced thrust, less heat generation, and increased work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

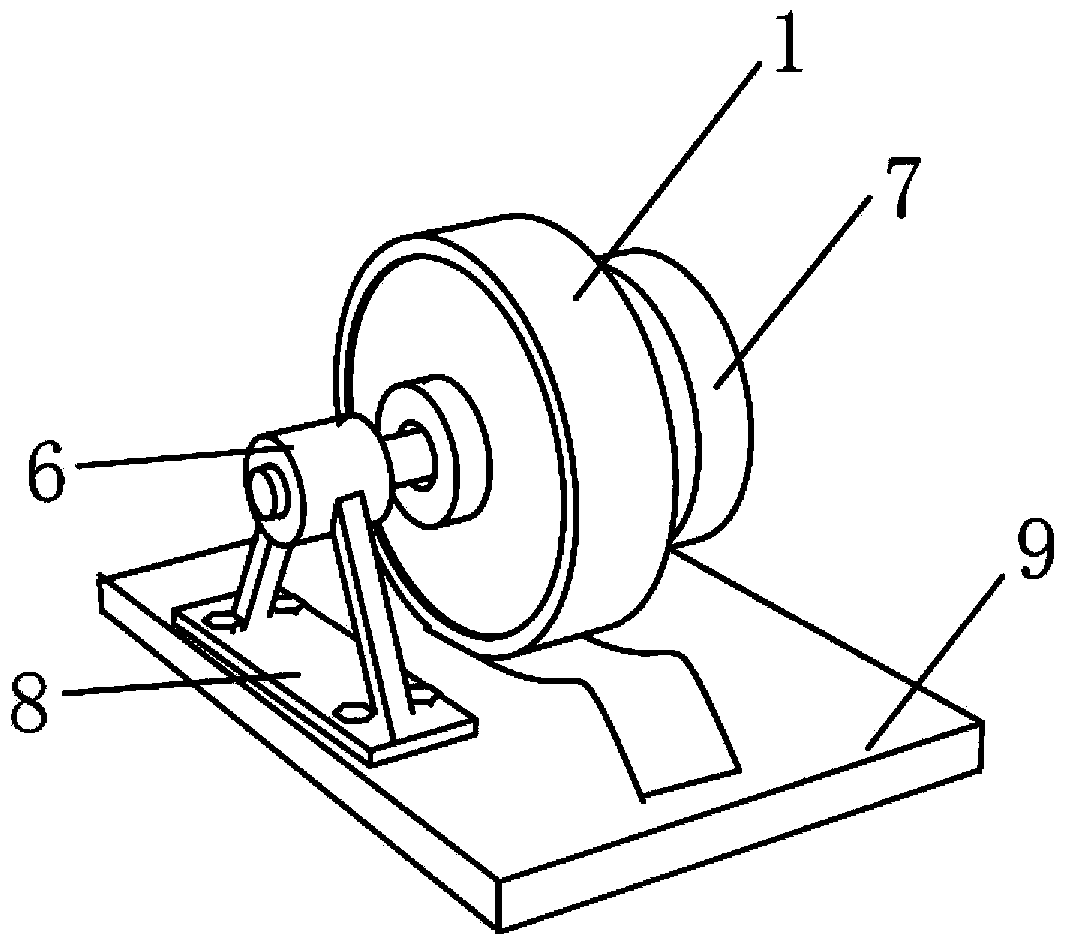

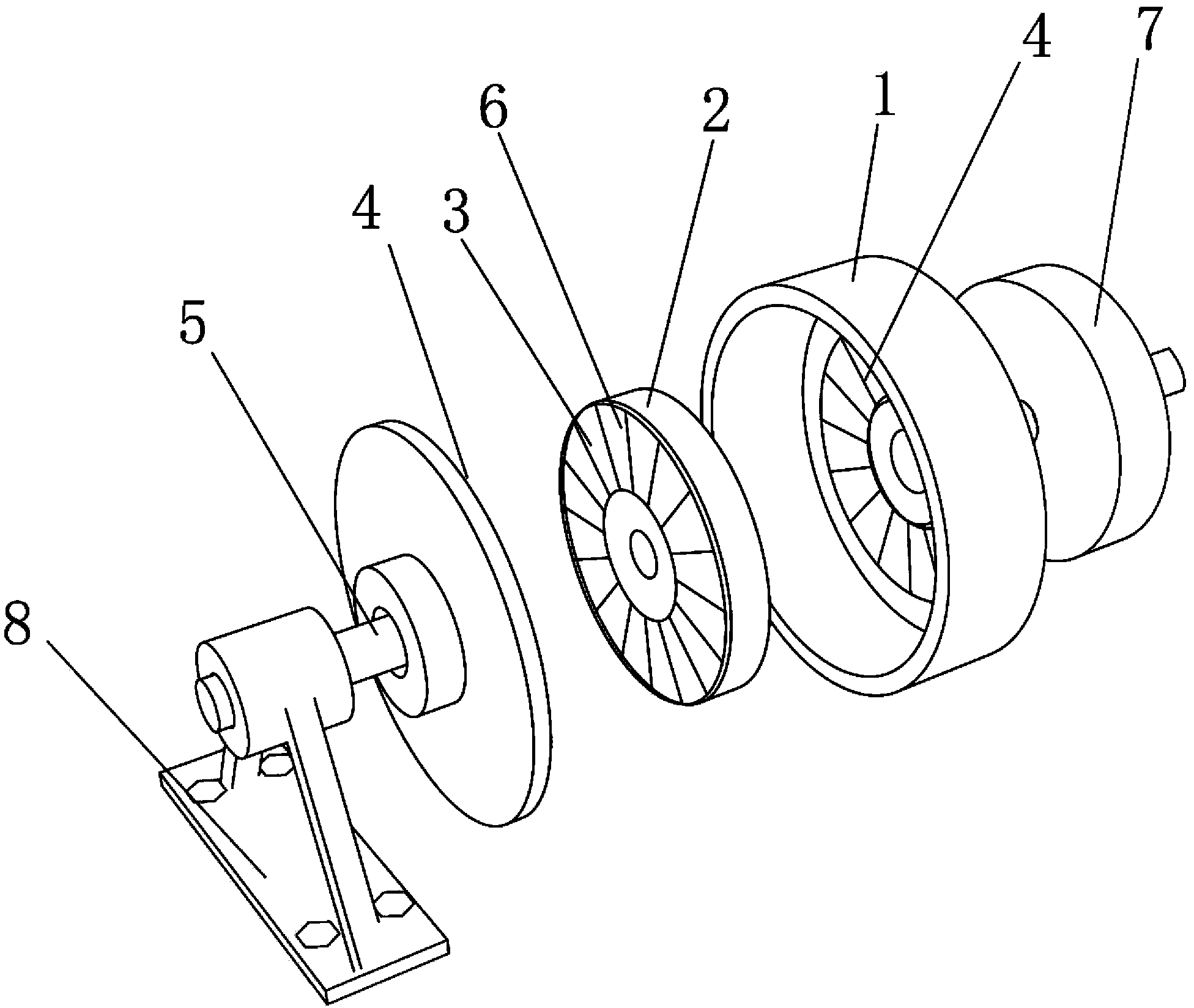

[0035] The bidirectional motor of the present invention is described below in conjunction with accompanying drawing and embodiment:

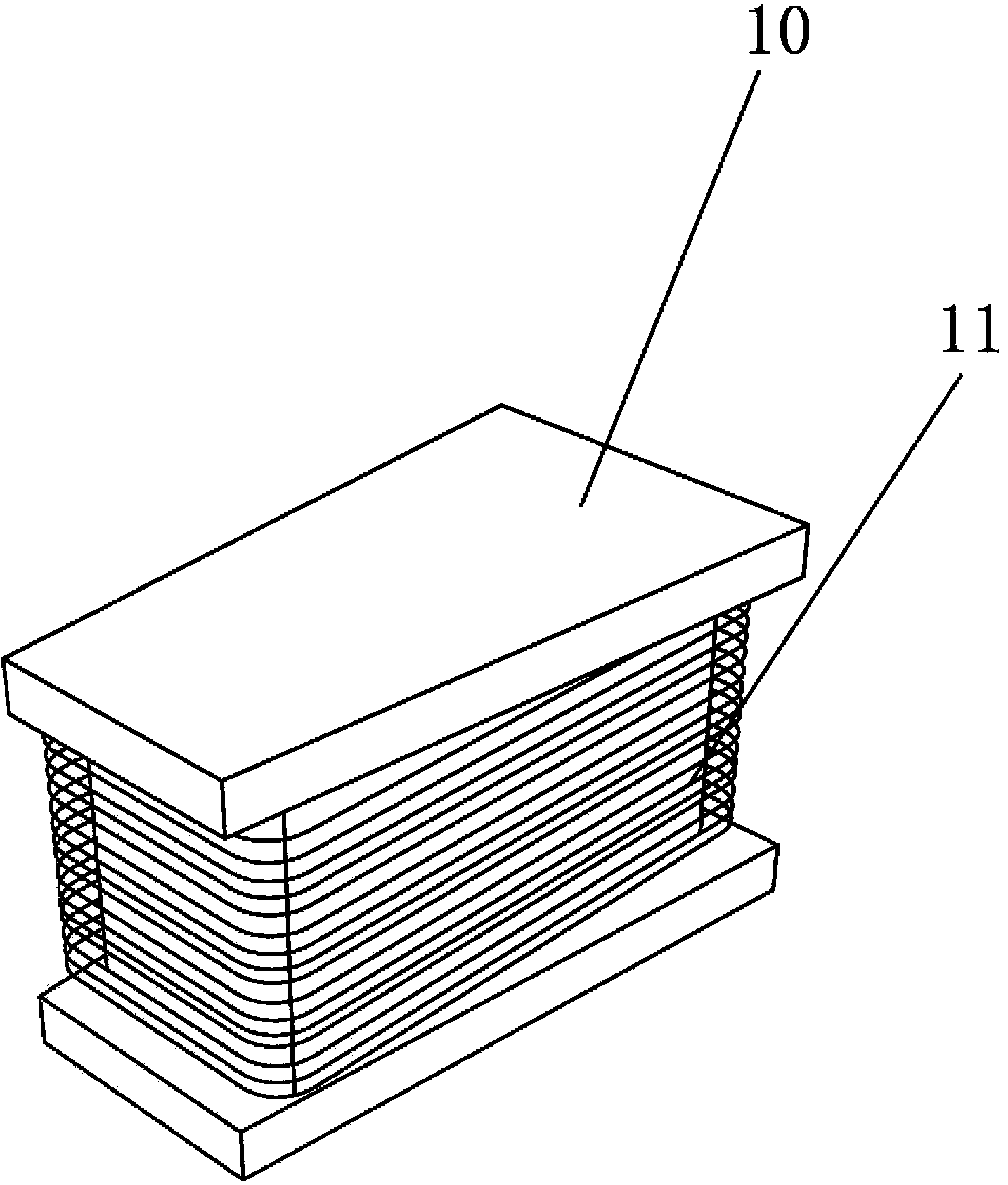

[0036] Such as Figure 1-3 As shown, the two-way motor in the present invention, the motor cover 1 and the coil support 2, the power shaft 5 is fixed on both sides of the coil support 2, and the coil support 2 is matched and installed in the bearing of the motor cover 1 through the power shaft 5. In this embodiment Among them, the coil support 2 is provided with 6 through-slots 3, and the through-slots 3 are circularly distributed in the center of the coil support 2, and the number of the through-slots 3 is an odd number. In this embodiment, there are seven through-slots 3. The slot 3 is inlaid with a wire core 10 in the shape of "I", and the wire core 10 is trapezoidal; the wire core 10 is wound with a coil 11, and the side cover of the motor cover 1 is provided with a magnet 4, and the number of the magnet 4 is the same as that of the slot. 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com