Perovskite solar battery based on CdSe nanocrystals and preparation method

A technology of nanocrystals and solar cells, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as device efficiency gaps, and achieve the effects of reducing recombination, reducing production costs, and high photoelectric energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

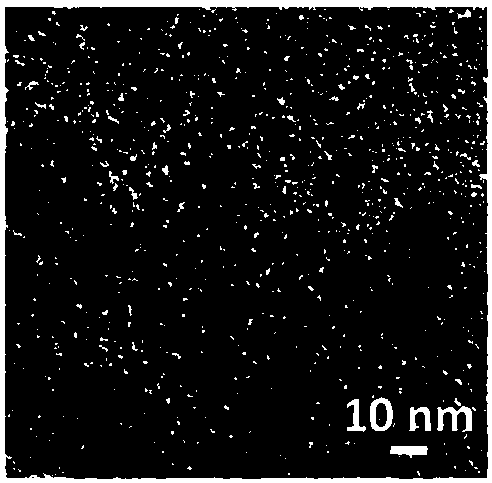

[0049] CdSe quantum dots were prepared by thermal injection method with an average particle size of 6.7 nm, figure 2 Its transmission electron microscope picture.

[0050] A solution was prepared by dissolving 35 mg of CdSe quantum dots in 1 ml of a mixed solvent of chlorobenzene and pyridine.

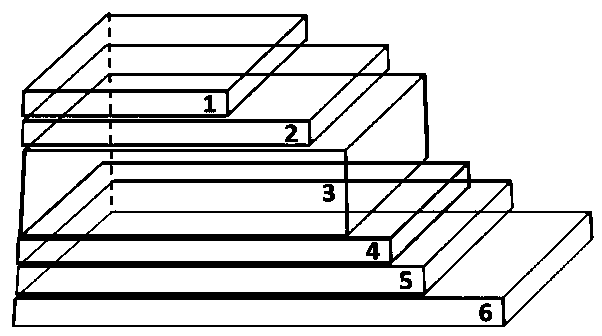

[0051] The transparent conductive glass etched with strip-shaped indium tin oxide (ITO, cathode) on the surface was ultrasonically oscillated for 15 minutes with aqueous detergent solution, deionized water, acetone and isopropanol, dried, and then treated with oxygen plasma 15 minutes; Then spin-coat the CdSe nanocrystal solution on the indium tin oxide (ITO) cathode with glass as the substrate, spin-coat for 40 seconds at a speed of 2000rpm (rev / min), and spin-coat twice under the above conditions to obtain a thickness of 50 nm CdSe film, 140 o C annealed for 10 min; then, spin-coated CH on the electron transport layer of the CdSe nanofilm at 2500 rpm 3 NH 3 I 3 / PbI 2 The mixe...

Embodiment 2

[0054] CdSe quantum dots were prepared by thermal injection method with an average particle size of 6.7 nm, as figure 2 shown.

[0055] A solution was prepared by dissolving 35 mg of CdSe quantum dots in 1 ml of a mixed solvent of chlorobenzene and pyridine.

[0056] The transparent conductive glass etched with strip-shaped indium tin oxide (ITO, cathode) on the surface was ultrasonically oscillated for 15 minutes with aqueous detergent solution, deionized water, acetone and isopropanol, dried, and then treated with oxygen plasma 15 minutes; Then spin-coat the CdSe nanocrystal solution on the indium tin oxide (ITO) cathode with glass as the substrate, spin-coat for 40 seconds at a speed of 2000rpm (rev / min), and spin-coat twice under the above conditions to obtain a thickness of 50 nm CdSe film, 100 o C annealed for 10 min; then, spin-coated CH on the electron transport layer of the CdSe nanofilm at 2500 rpm 3 NH 3 I 3 / PbI 2 The mixed solution, the molar ratio of which...

Embodiment 3

[0059] CdSe quantum dots were prepared by thermal injection method with an average particle size of 6.7 nm, as figure 2 shown.

[0060] A solution was prepared by dissolving 35 mg of CdSe quantum dots in 1 ml of a mixed solvent of chlorobenzene and pyridine.

[0061] The transparent conductive glass etched with strip-shaped indium tin oxide (ITO, cathode) on the surface was ultrasonically oscillated for 15 minutes with aqueous detergent solution, deionized water, acetone and isopropanol, dried, and then treated with oxygen plasma 15 minutes; Then spin-coat the CdSe nanocrystal solution on the indium tin oxide (ITO) cathode with glass as the substrate, spin-coat for 40 seconds at a speed of 2000rpm (rev / min), and spin-coat twice under the above conditions to obtain a thickness of 50 nm CdSe film, 120 o C annealed for 10 min; then, spin-coated CH on the electron transport layer of the CdSe nanofilm at 2500 rpm 3 NH 3 I 3 / PbI 2 The mixed solution, the molar ratio of which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com