Preparation method of low temperature polysilicon film

A low-temperature polysilicon and thin-film technology, applied in semiconductor/solid-state device manufacturing, gaseous chemical plating, coating, etc., can solve problems such as the absence of very effective countermeasures, and achieve optimal surface roughness, good stability, and uniformity good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a method for preparing a photoelectric device, in particular a method for preparing a low-temperature polysilicon thin film.

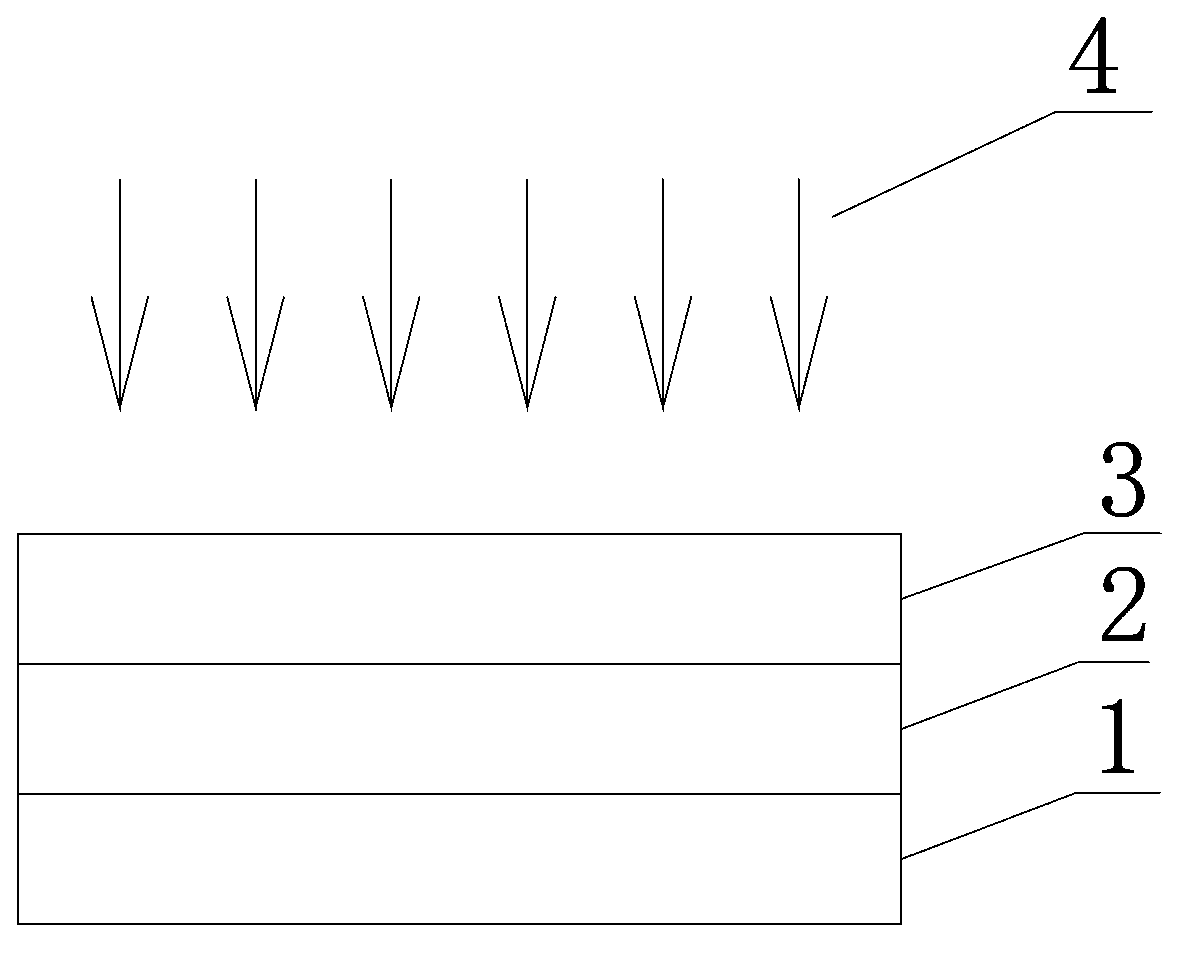

[0035] The core idea of the present invention is to provide a substrate; prepare an amorphous silicon layer on the substrate; prepare a silicon oxide layer on the amorphous silicon layer by using a plasma process; perform laser polysilicon on the amorphous silicon layer chemical process.

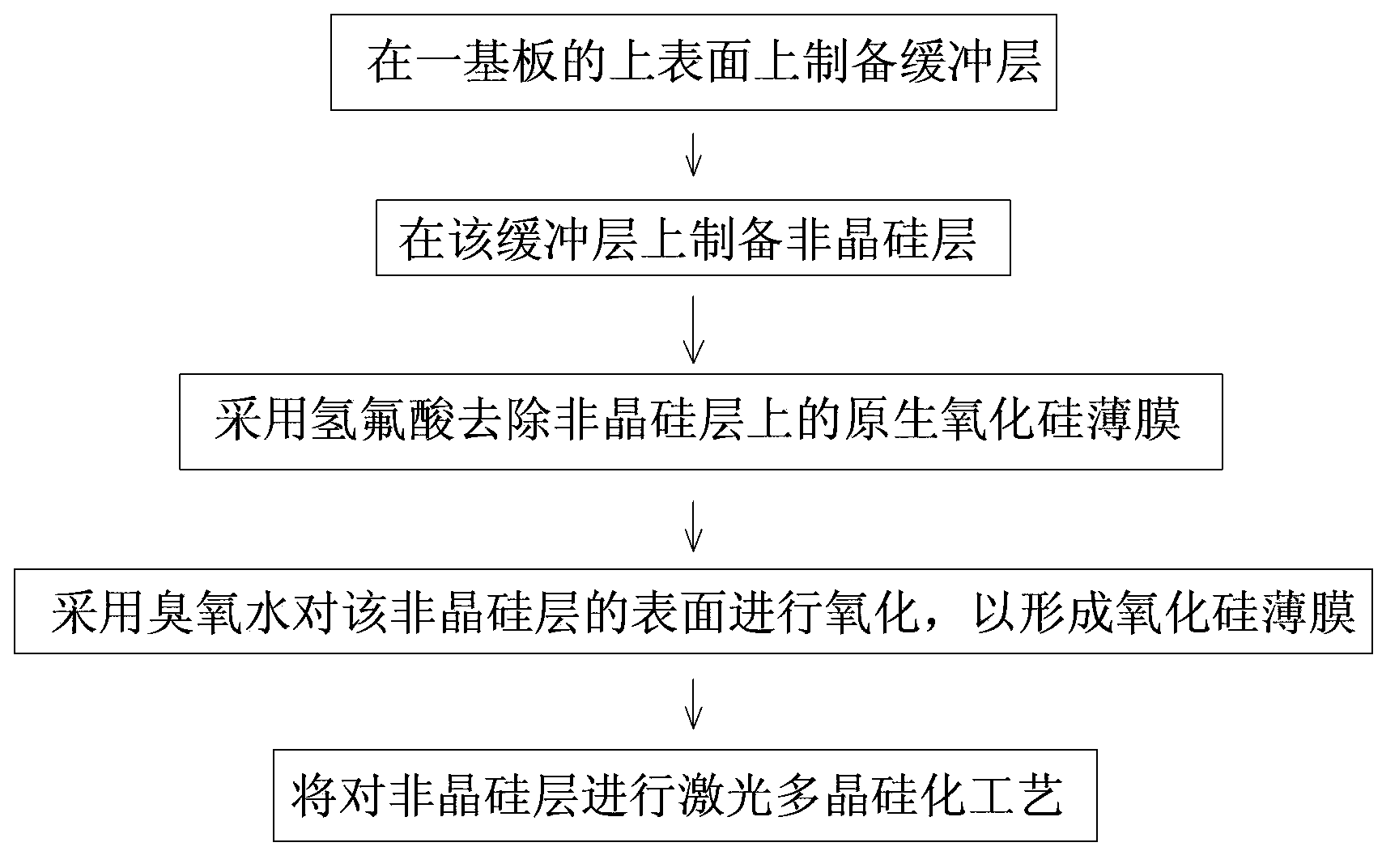

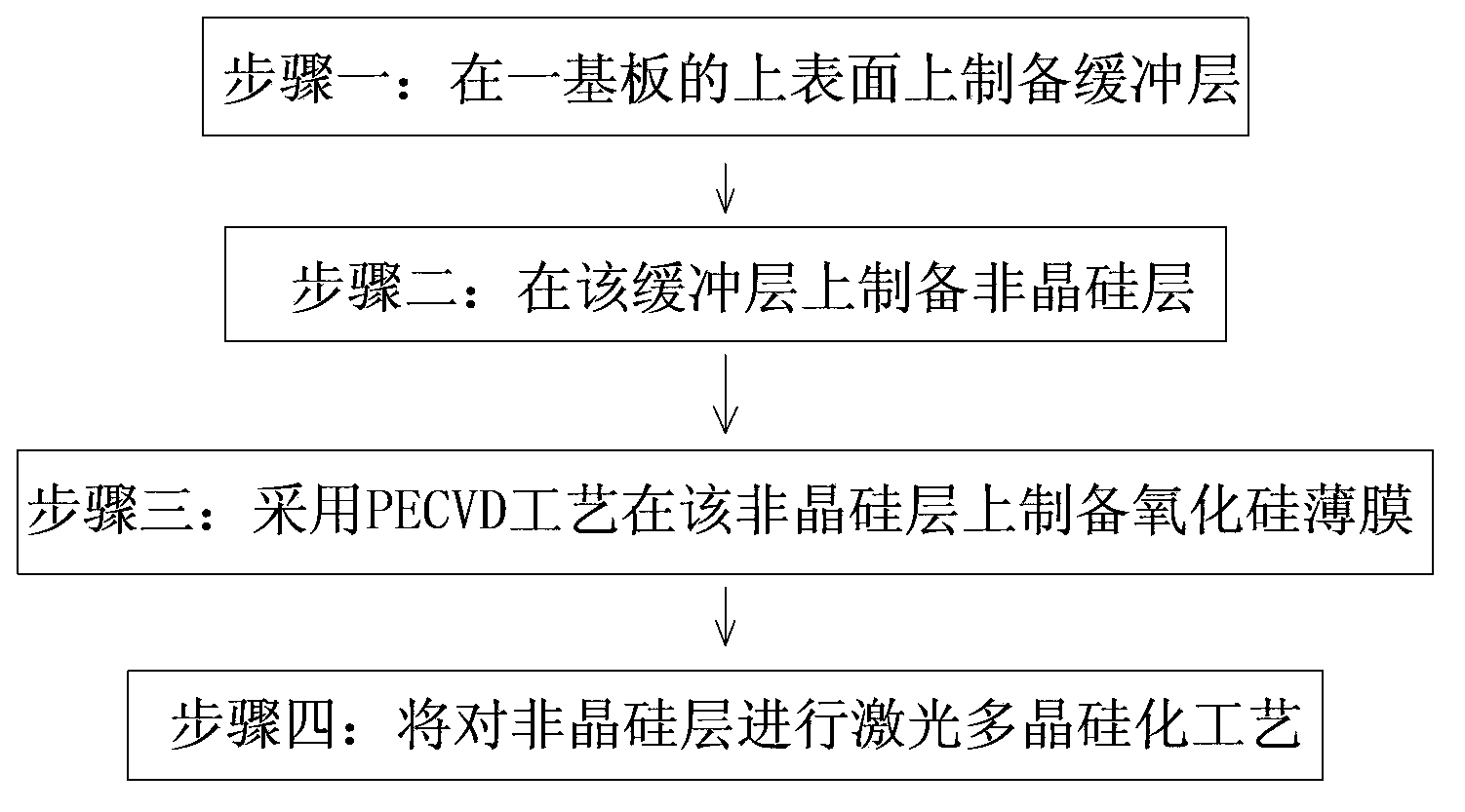

[0036] figure 2 It is a schematic diagram of the steps of the method for preparing a low-temperature polysilicon thin film in Embodiment 1 of the present invention, as figure 2 Shown:

[0037] The preparation method of low-temperature polysilicon film among the present invention comprises the following steps:

[0038] Step 1: Prepare a buffer layer on a substrate so that the buffer layer covers the upper surface of the substrate. In this embodiment, the substrate in the preparation of the low-temperature polysilicon thin film may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com