Transformer insulating sleeve temperature online monitoring system

An insulating sleeve and monitoring system technology, applied in thermometers, thermometer parts, instruments, etc., can solve problems such as large errors, missed reports of faults, and inability to achieve real-time monitoring, so as to avoid missed reports of faults and ensure accurate data. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

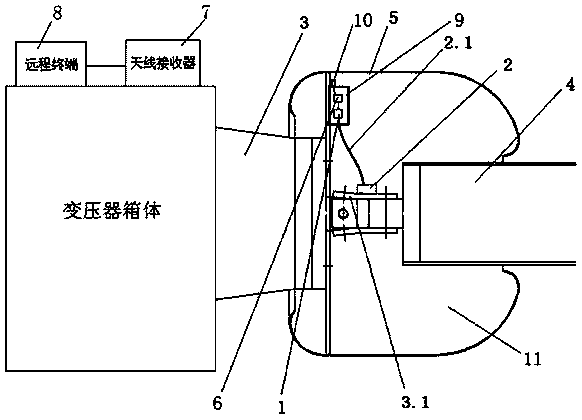

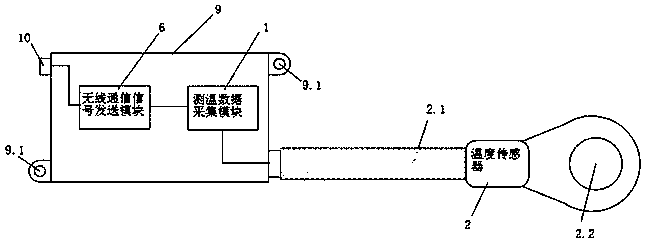

[0013] Such as figure 1 with figure 2 The transformer insulating bushing temperature online monitoring system shown includes a transformer insulating bushing 3, a bushing insert 4 and a voltage equalizing cover 5. The end of the transformer insulating bushing 3 is provided with a bushing edge 3.1. The end of the transformer insulating bushing 3 is clamped with the bushing inserting plate 4 through the bushing edge 3.1, and the pressure equalizing cover 5 seals and wraps the connection between the transformer insulating bushing 3 and the bushing inserting plate 4, so that The pressure equalizing cover 5 is filled with transformer oil 11, and it also includes a temperature sensor 2, a temperature measurement data acquisition module 1, a wireless communication signal sending module 6, a sending end antenna 10, an antenna receiver 7 and a remote t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com