Method for preparing magnesium

A technology of metal magnesium and magnesium vapor, applied in the field of metallurgy, can solve problems such as difficult to achieve continuous production, serious environmental pollution, and difficult to use reducing slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

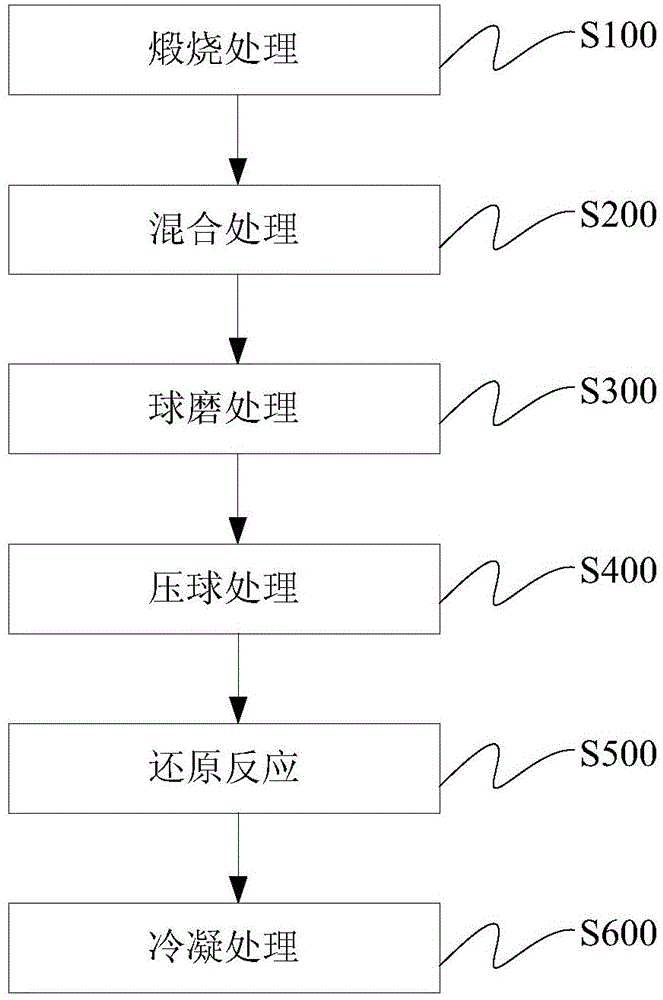

Method used

Image

Examples

Embodiment 1

[0088] The dolomite is crushed to an average particle size of not more than 25mm, and calcined in a rotary kiln at a temperature of 1250°C; the “calcined white” cooled to room temperature and the reducing agent ferrosilicon are prepared according to Si(Fe):MgO=2.2 (mole Ratio) batching, and then add 2% fluorite of the total of the two mixtures, after mixing, send it into the ball mill for grinding until the average particle size is 0.2mm, when the pressure of the ball press is 10MPa, the mixture Press into elliptical pellets; control the strong reducing atmosphere in the rotary hearth furnace. In the rotary hearth furnace, the pellets are reduced through the feeding area, preheating area, heating area, high temperature area, control area, and discharge area with the rotation of the rotary hearth furnace. The reduction time is 4 hours. The metal magnesium produced during the reduction process The steam crystallizes on the condenser on the top of the furnace, and the temperature...

Embodiment 2

[0090]The dolomite is crushed to an average particle size of not more than 35mm, and calcined in a rotary kiln at a temperature of 1200°C; the "calcined white" cooled to room temperature and the reducing agent ferrosilicon are prepared according to Si(Fe):MgO=2.8 (mole Ratio) ingredients, and then add the total 3% fluorite of the two mixtures, after mixing, send them into the ball mill for grinding until the average particle size is below 1mm, and press the mixture when the pressure of the ball press is 10MPa Form elliptical pellets; control the strong reducing atmosphere in the rotary hearth furnace. In the hearth furnace, the pellets are reduced through the feeding area, preheating area, heating area, high temperature area, control area, and discharge area with the rotation of the rotary hearth furnace. The reduction time is 1h. The metal magnesium vapor generated during the reduction process Crystallize on the condenser on the top of the furnace. The temperature of the cond...

Embodiment 3

[0092] The dolomite is crushed to an average particle size of not more than 35mm, and calcined in a rotary kiln at a temperature of 1200°C; the "calcined white" cooled to room temperature and the reducing agent ferrosilicon are prepared according to Si(Fe):MgO=2.5 (mole Ratio) batching, and then add 3% fluorite of the total of the two mixtures, after mixing, send them into the ball mill for grinding to an average particle size below 0.5mm, and mix the mixture when the pressure of the ball press is 10MPa Press into elliptical pellets; control the strong reducing atmosphere in the rotary hearth furnace, the maximum reduction temperature of the rotary hearth furnace is 1220°C, and the pressure in the furnace is between 13 and 15Pa. In the rotary hearth furnace, the pellets go through the feeding area, preheating area, heating area, high temperature area, control area, and discharge area successively with the rotation of the rotary hearth furnace for reduction. The reduction time i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com