Sintered ore quality control method in sintering process

A quality control method and sintering process technology, applied in the field of iron and steel production and processing, can solve the problems of large difference in composition, complex calculation of ingredients, and poor sampling representativeness, and achieve the effects of easy to master and operate, simple calculation method, and improved predictive ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

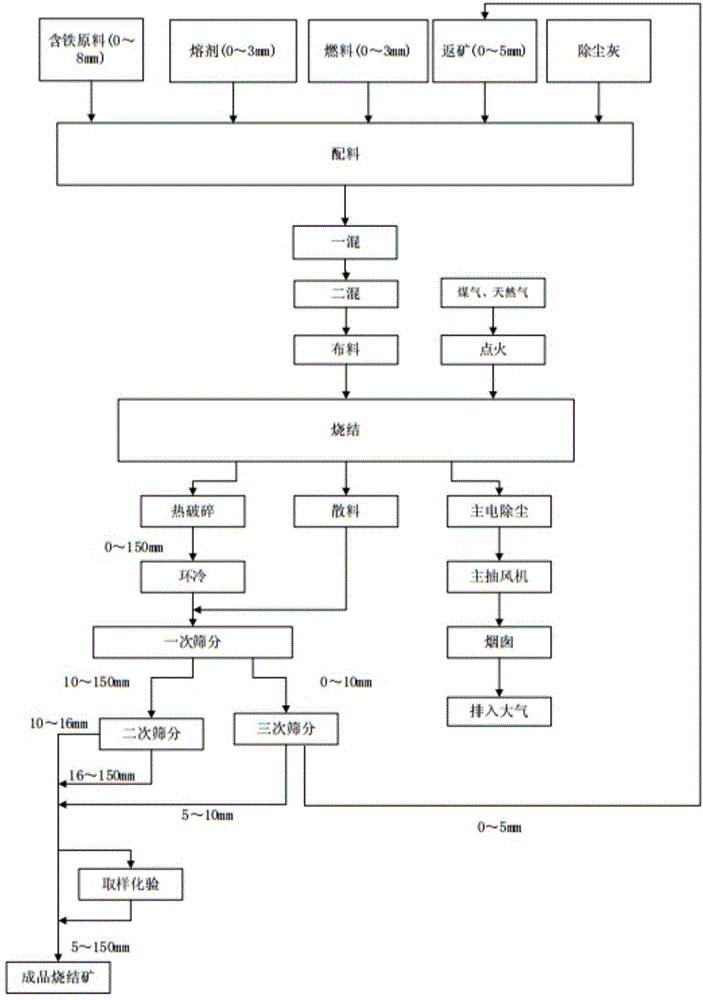

Method used

Image

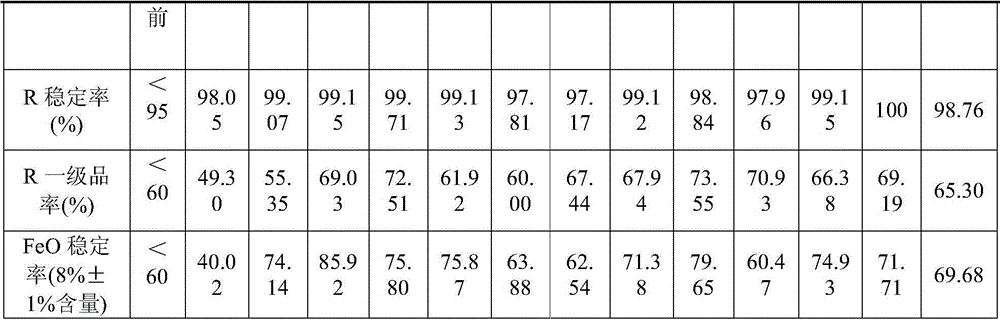

Examples

Embodiment 1

[0043] A. The total amount of sintering materials is 400t, including 160t total return ore, 12t fuel, 12t limestone, 7.2t dolomite, 14.4t quicklime, 194.4t mixed ore, 10t dedusting ash, 45% effective calcium content of limestone, and 45% quicklime The effective calcium content is 75%, the effective calcium content of dolomite is 35%, and the target product sinter requires R to be 2.

[0044] B. When batching, the CaO mass ratio of limestone, dolomite, and quicklime is 10:6:15, that is, if the alkalinity is adjusted, the amount of quicklime needs to be increased by 1t, and by adjusting the limestone, it needs 1.5t, and if the dolomite is adjusted, it needs to be 2.5t .

[0045] C. When batching, test the SiO of dust removal 2 content and CaO content, the test result is SiO 2 CaO content is 6%, CaO content is 10.8%, and R is 1.8, which is 0.2 lower than the requirement. Therefore, it is necessary to use flux to adjust the CaO content of dust removal ash, and it is necessary to...

Embodiment 2

[0050]A. The total amount of sintering materials is 400t, including 160t of external ore, 12t of fuel, 7.2t of dolomite, 12t of limestone, 14.4t of quicklime, 194.4t of mixed ore, and 10t of dedusting ash. The R required for the target product sinter is: 2. The effective calcium content of limestone is 50%, the effective calcium content of quicklime is 85%, and the effective calcium content of dolomite is 30%.

[0051] B. When batching, the CaO mass ratio of limestone, dolomite, and quicklime is 10:6:17, that is, if the alkalinity is adjusted, the amount of quicklime needs to be increased by 1t, while the adjustment of limestone requires 1.7t, and the adjustment of dolomite requires 2.83t .

[0052] C. When batching, test the SiO of dust removal 2 content and CaO content, the test result is SiO 2 CaO content is 6%, CaO content is 10.8%, R is 1.8, which is 0.2 lower than the requirements, so it is necessary to use flux to adjust the CaO content of dedusting ash, and it is nec...

Embodiment 3

[0057] A. The total amount of sintering materials is 400t, including 160t of external ore, 12t of fuel, 7.2t of dolomite, 12t of limestone, 14.4t of quicklime, 194.4t of mixed ore, and 10t of dust removal ash. The production requirement of sintering is 2. The effective calcium content of limestone is 55%, the effective calcium content of quicklime is 80%, and the effective calcium content of dolomite is 30%.

[0058] B. When batching, the CaO mass ratio of limestone, dolomite, and quicklime is 10:6:16, that is, if the alkalinity is adjusted, the amount of quicklime needs to be increased by 1t, and by adjusting the limestone, it needs 1.6t, and if the dolomite is adjusted, it needs 2.67t .

[0059] C. When batching, test the SiO of dust removal 2 content and CaO content, the test result is SiO 2 CaO content is 6%, CaO content is 10.8%, R is 1.8, which is 0.2 lower than the requirement, so it is necessary to use flux to adjust the CaO content of dedusting ash, and it is necess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com