Method using acetic acid for controlled catalysis of orientational hydrolysis of xylan to prepare multicomponent xylooligosaccharide

A technology of xylooligosaccharides and catalytic wood, which is applied in the fields of food engineering and chemical engineering, can solve the problems of high requirements for the production of enzyme preparations, and achieve the effects of overcoming many toxic decomposition products, simple process, and high yield cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In a 1L mechanically stirred stainless steel high-pressure reaction tank bottle, add 700mL of reactants containing 10% (mass percentage, the same below) xylan and 20% (mass percentage, the same below) edible acetic acid, seal it, and turn on the stirring speed of 150r / min, heated to 120°C for 2 hours, and quickly cooled the reaction system to room temperature in a water bath to obtain a reaction solution.

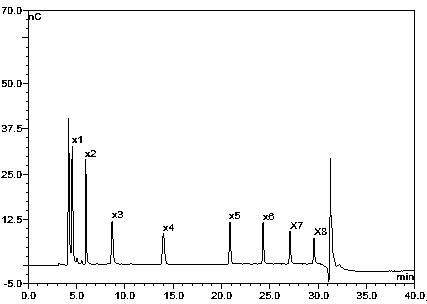

[0018] The components of the reaction solution were detected by high-performance liquid chromatography, and the chromatographic conditions were: American Dionex ICS-3000 ion chromatography system, equipped with CarboPac TM PA200 (3mm×250mm) chromatographic column and retention column (3×50mm), ED electrochemical detector, column temperature 30°C, injection volume 10.0μL; 100mmol / L sodium hydroxide-500mmol / L sodium acetate solution (A ) and 100mmol / L sodium hydroxide solution (B) as the eluent for binary gradient elution at a flow rate of 0.3mL / min (elution program,...

Embodiment 2

[0021] Add 600mL reactants containing 20% xylan and 30% edible acetic acid to a 1L mechanically stirred stainless steel high-pressure reaction tank bottle, seal it, turn on the stirring speed at 160r / min, heat to 130°C for 1.5h, and quickly cool in a water bath The reaction system was brought to room temperature to obtain a reaction liquid. A microfiltration membrane device is used to separate the reaction liquid, intercept unhydrolyzed xylan and pass through the xylooligosaccharide liquid. Then, the nanofiltration membrane device is used to separate the reaction solution by batch replenishment, retain more than 95% of the xylo-oligosaccharide component, pass through more than 98% of acetic acid and more than 92% of xylose, and obtain the xylo-oligosaccharide product liquid. The acetic acid solution was reused. The composition of the reaction solution was detected by high performance liquid phase ion chromatography, the method was the same as in Example 1, the results showe...

Embodiment 3

[0023] Add 550mL reactants containing 15% xylan and 15% edible acetic acid to a 1L mechanically stirred stainless steel high-pressure reaction tank bottle, seal it, turn on the stirring speed of 150r / min, heat to 110°C for 3 hours, and quickly cool the reaction in a water bath The system was brought to room temperature to obtain a reaction solution. A microfiltration membrane device is used to separate the reaction liquid, intercept unhydrolyzed xylan and pass through the xylooligosaccharide liquid. Then, the nanofiltration membrane device is used to separate the reaction solution by batch replenishment, retain more than 95% of the xylo-oligosaccharide component, pass through more than 98% of acetic acid and more than 92% of xylose, and obtain the xylo-oligosaccharide product liquid. The acetic acid solution was reused. High-performance liquid phase ion chromatography was used to detect the components of the reaction solution. The method was the same as in Example 1. Formic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com