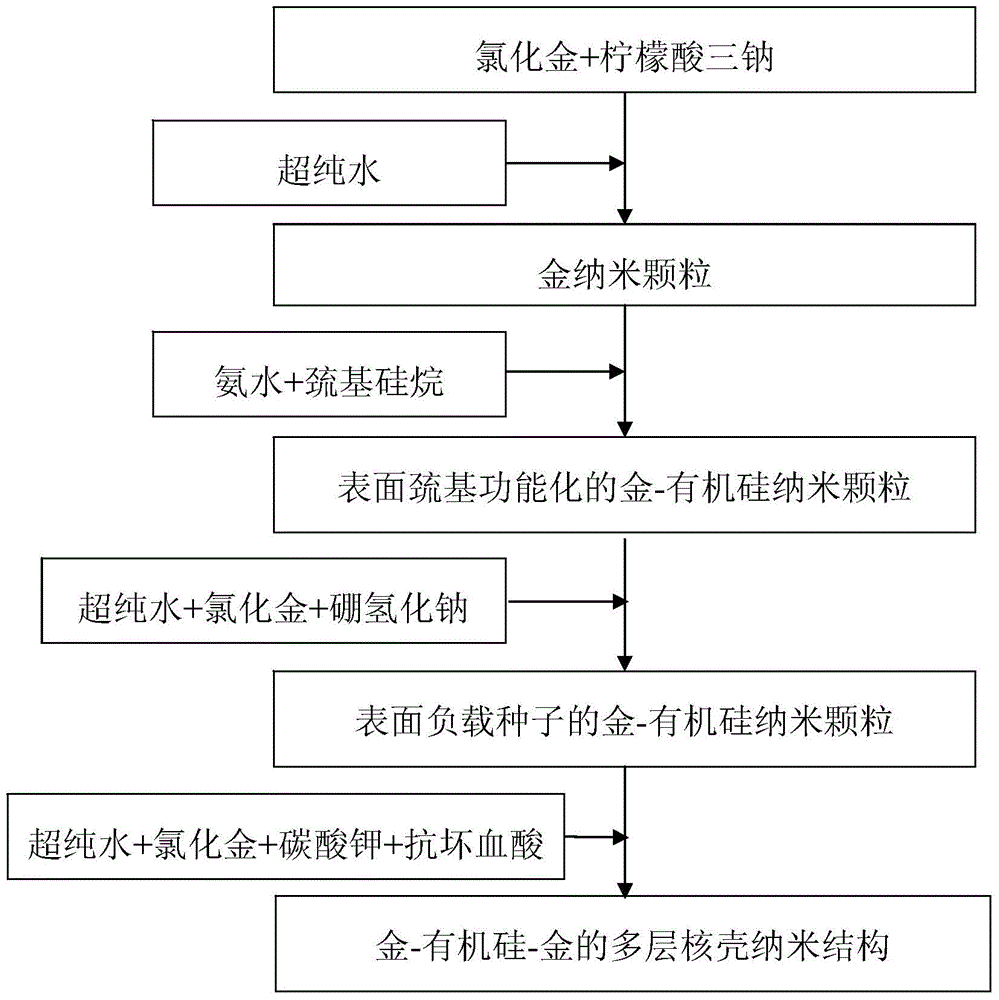

Gold-organic silicon-gold multilayer core-shell nano-structure and preparing method and application thereof

A nanostructure, organosilicon technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of poor preparation effect, unstable performance, and complex preparation process of multi-layer core-shell nanostructures. and other problems, to achieve the effect of excellent photothermal therapy ability, good effect and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] At room temperature, mix gold chloride and trisodium citrate at a molar ratio of 25:300, add 72ml of ultrapure water and mix evenly to obtain a bright red colloidal solution, heat the solution to boil and keep it for 15 minutes, then cool down to about 85°C. Continue to add gold chloride and trisodium citrate to the above solution at a molar ratio of 30:75, stir at 85°C for half an hour and then centrifuge to obtain 70ml of dark red colloidal solution dispersed with gold nanoparticles.

[0045] Take 16ml of the above colloidal solution, add 0.2mg of ammonia water and 0.03mg of 3-mercaptopropyltriethoxysilane (MPTES) directly according to the molar ratio of gold nanoparticles, ammonia water and mercaptosilane at 2:300:15, shake for 90s and then let stand for 12h , so as to form a surface mercapto-functionalized intermediate dielectric layer composed of organosilicon on the surface of the gold nanoparticles, thereby obtaining surface-mercapto-functionalized gold-organosili...

Embodiment 2

[0052] At room temperature, mix gold chloride and trisodium citrate at a molar ratio of 25:250, add 72ml of ultrapure water and mix evenly to obtain a bright red colloidal solution, heat the solution to boil and keep it for 15 minutes, then cool down to about 70°C. Continue to add gold chloride and trisodium citrate to the above solution at a molar ratio of 20:100, stir at 70°C for half an hour and then centrifuge to obtain 70ml of dark red colloidal solution dispersed with gold nanoparticles.

[0053] Take 16ml of the above colloidal solution, add 0.2mg of ammonia and 0.04mg of 3-mercaptopropyltriethoxysilane (MPTES) directly according to the molar ratio of gold nanoparticles, ammonia and mercaptosilane at 1:300:20, shake for 90s and let it stand for 12h , so as to form a surface mercapto-functionalized intermediate dielectric layer composed of organosilicon on the surface of the gold nanoparticles, thereby obtaining surface-mercapto-functionalized gold-organosilicon nanoparti...

Embodiment 3

[0058] At room temperature, mix gold chloride and trisodium citrate at a molar ratio of 30:250, add 72ml of ultrapure water and mix evenly to obtain a bright red colloidal solution, heat the solution to boil and keep it for 15 minutes, then cool down to about 90°C. Continue to add gold chloride and trisodium citrate to the above solution at a molar ratio of 40:100, stir at 90°C for half an hour and then centrifuge to obtain 70ml of dark red colloidal solution dispersed with gold nanoparticles.

[0059] After taking 16ml of the above colloidal solution, add 0.2mg of ammonia water and 0.018mg of 3-mercaptopropyltriethoxysilane (MPTES) directly according to the molar ratio of gold nanoparticles, ammonia water and mercaptosilane at a ratio of 6:300:9 and let it stand for 12h after shaking for 90s , so as to form a surface mercapto-functionalized intermediate dielectric layer composed of organosilicon on the surface of the gold nanoparticles, thereby obtaining surface-mercapto-funct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com