Solid-phase micro-extraction fiber and preparation method thereof

A technology for extracting fibers and capillaries, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of poor stability and non-universality of solid-phase microextraction materials, and achieve easy control, reduced production costs, and uniform pores Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

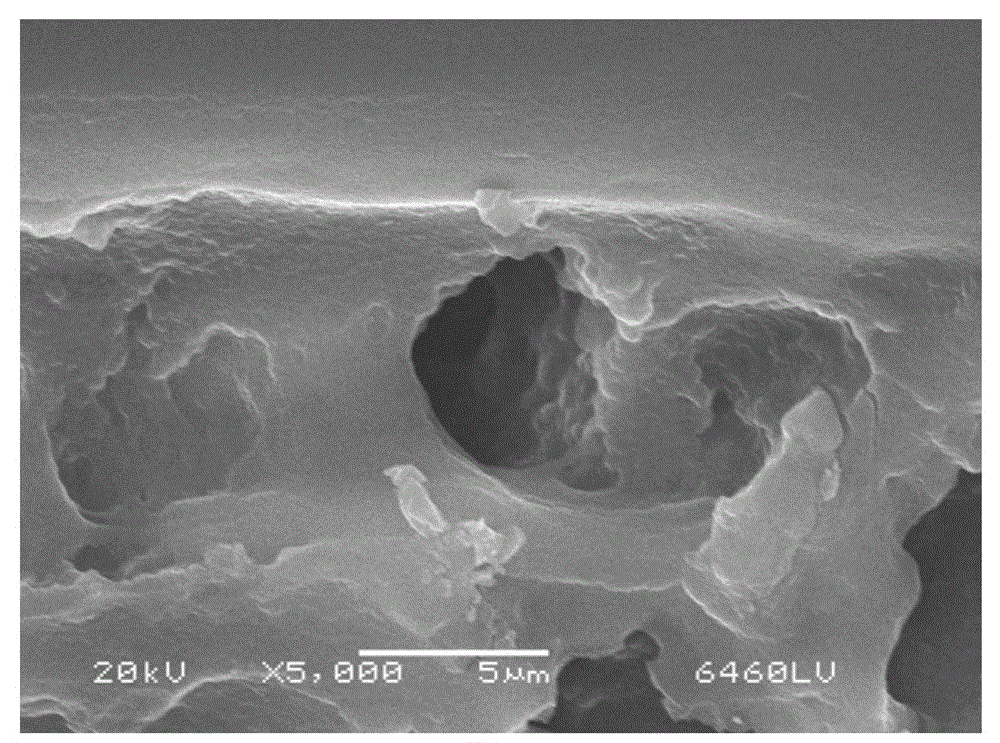

Image

Examples

preparation example Construction

[0018] The embodiment of the present invention provides a method for preparing solid-phase microextraction fibers. The method comprises the steps of:

[0019] S01. Prepare a mixed organic solution containing α-methacrylic acid, styrene, organic crosslinking agent, organic porogen, and azo initiator: mix α-methacrylic acid, styrene, organic crosslinking agent, and organic porogen , the azo initiator is mixed and processed to obtain a mixed organic solution;

[0020] S02: After placing the mixed organic solution in an oxygen-free environment, inject a capillary into the mixed organic solution prepared in step S01, and fill the mixed organic solution into the cavity of the capillary;

[0021] S03: Continue to heat the mixed organic solution with the capillary to 50-70°C in an oxygen-free environment to carry out the polymerization reaction, wash and remove the capillary after the polymerization reaction to obtain a solid Phase microextraction fibers.

[0022] Specifically, in ...

Embodiment 1

[0046] A solid-phase microextraction fiber and a preparation method thereof. The preparation method of this solid-phase microextraction fiber comprises the steps:

[0047] S11: Accurately measure 672 μL of α-methacrylic acid, 168 μL of styrene, 2016 μL of ethylene glycol dimethacrylate, 1008 μL of toluene, and 45.6 mg of azobisisobutyronitrile;

[0048] S12: ultrasonically vibrate each component measured in step S11 for 15 minutes at room temperature, so that each component is uniformly mixed and dissolved;

[0049] S13: Transfer the mixed solution prepared in step S12 to a watch glass, and seal it with plastic wrap (only one small hole is left), and blow nitrogen for 5 minutes;

[0050] S14: The specification is 50μL (specification: length: 125mm, outer diameter / internal warp) into the watch glass, so that the capillary is filled with the mixed solution, and continue to blow nitrogen for 2min;

[0051] S15: completely seal the watch glass with plastic wrap, and polymeri...

Embodiment 2

[0056] A solid-phase microextraction fiber and a preparation method thereof. The preparation method of the solid phase microextraction fiber is as follows: figure 1 As shown, it includes the following steps:

[0057] S21: Accurately measure 504 μL of α-methacrylic acid, 168 μL of styrene, 1008 μL of trimethylpropane trimethacrylate, 2016 μL of dimethyl phthalate, and 34.95 mg of azobisisoheptanonitrile;

[0058] S22: ultrasonically vibrate each component measured in step S21 for 20 minutes at room temperature, so that each component is uniformly mixed and dissolved;

[0059] S23: Transfer the mixed solution prepared in step S22 to a watch glass, seal it with a plastic wrap (leaving only one small hole), and blow nitrogen for 8 minutes;

[0060] S24: The specification is 25μL (specification: length: 125mm, outer diameter / Nei Jing) capillary into a watch glass, so that the capillary is filled with the mixed solution, continue blowing nitrogen for 10min;

[0061] S25: compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com