Light guide elements for laser automotive headlights

A technology of light-guiding components and light-emitting components, which is applied in the direction of headlights, vehicle parts, electric light sources, etc., can solve the problems of harming traffic participants, eye laser rays, etc., and achieve the effect of high light output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

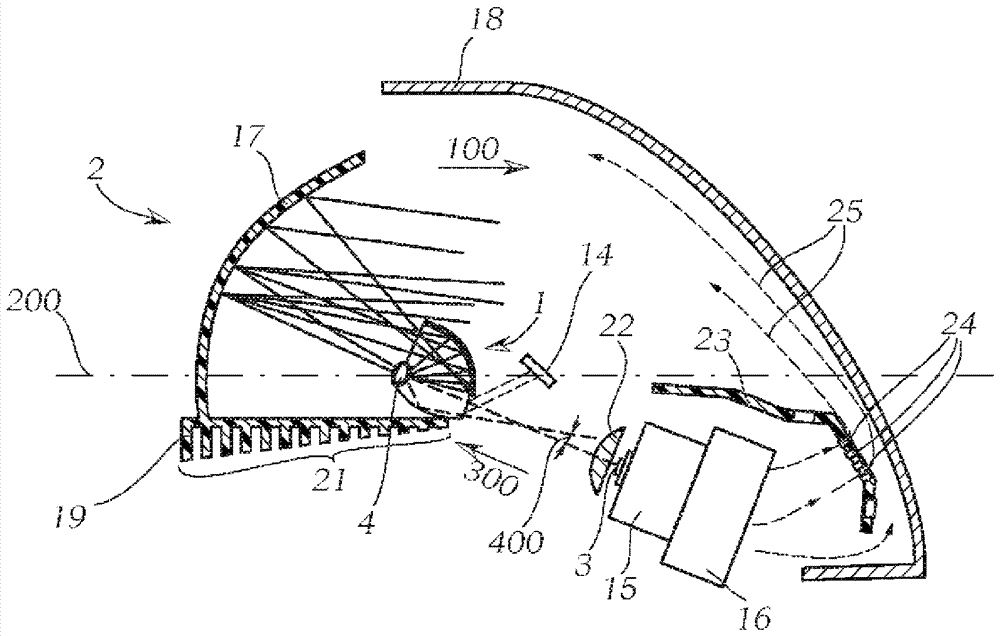

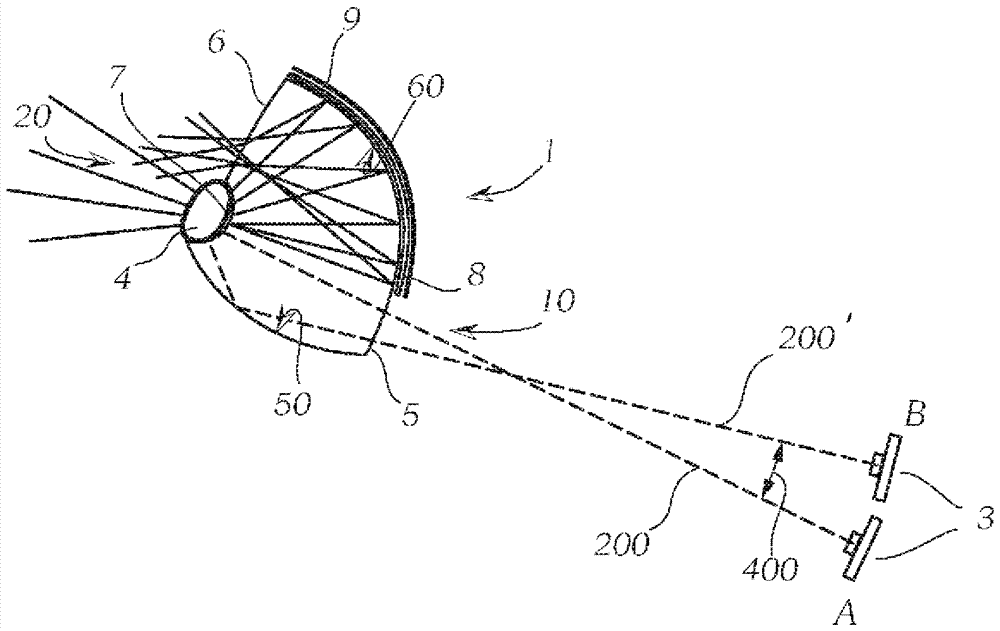

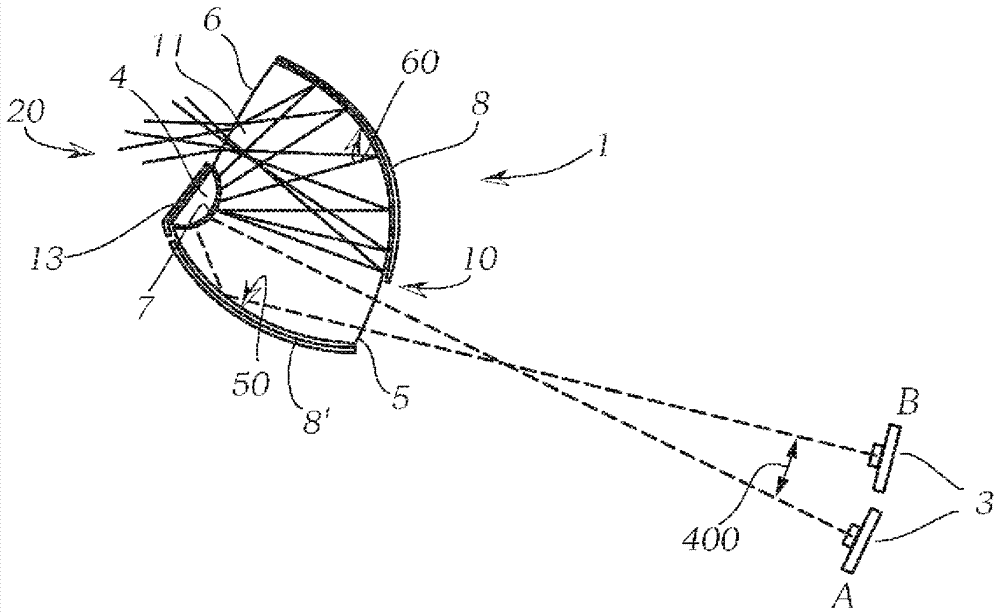

[0023] In the following figures, for the sake of clarity, identical components are assigned the same reference symbols. The terms used below such as "upper", "lower", "front" and "rear" relate to the state of assembly in a motor vehicle, if the light guide element 1 is also used in a motor vehicle headlight 2, which is front-mounted inside the car.

[0024] exist figure 1 A first variant of the light guiding element 1 according to the invention is shown in . The light guide element 1 is used, for example, in laser car headlights 2 (see image 3 ), and between the laser source 3 and the light-emitting element 4, the light-emitting element is excited for emitting visible light, especially white light, by the light incident from the laser source 3 . exist figure 1 Two different positions of the laser source 3 are shown in , as will be explained in more detail below.

[0025] The light guiding element 1 is preferably made of a transparent material, such as glass or plastic. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com