Installation for treating a fuel to increase its caloric power

A calorific value and fuel technology, which is applied in the field of devices for processing fuel to increase its calorific value, can solve the problems of magnetic field reduction, etc., and achieve the effects of increasing calorific value, easy transportation, loading and unloading, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

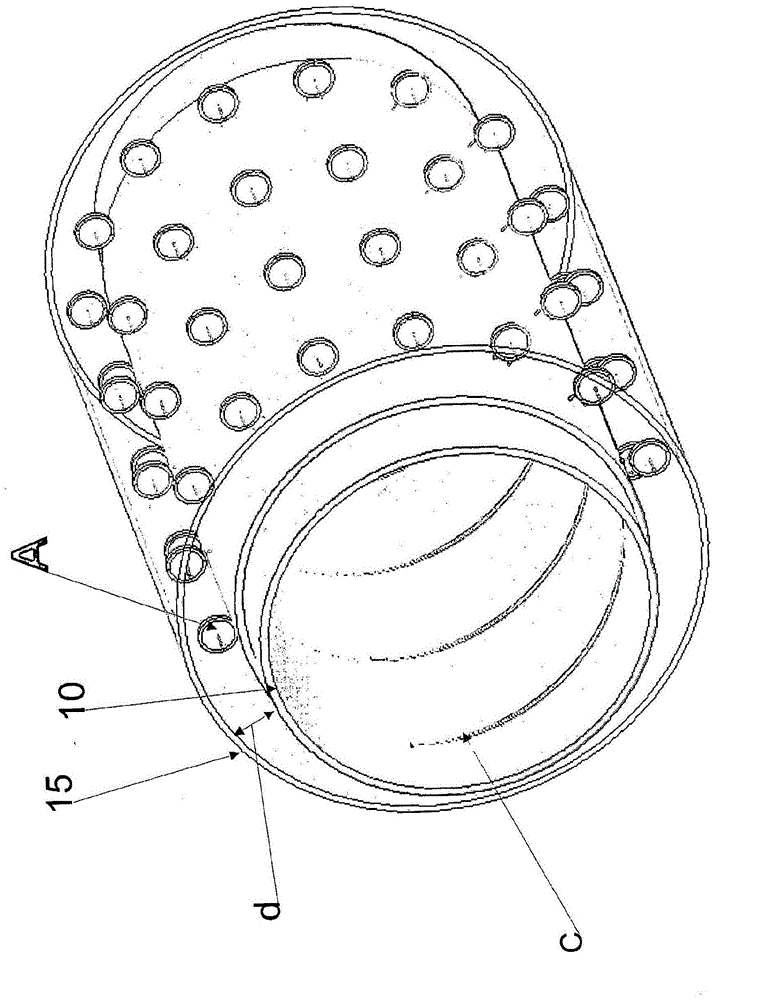

[0032] The device according to the claimed invention consists of several exciter units A with two half-assemblies 1 and 2 between which there are still some spaces a and b at the functioning position to isolate each other. Each of the half-fittings 1 and 2 is made of 99.99% electrolytic copper doped with a precious metal, preferably platinum, on the order of parts per million.

[0033] In front of the space a attached to the half-fittings 1 and 2 are long wire electrodes 3 and 4 made of good electrical conductors, preferably copper, which are insulated from the outside.

[0034] Inside the half-fittings 1 and 2 are placed inferior and superior circular electrodes 5 and 6 made of electrolytic copper. Between and in contact with the electrodes 5 and 6 is placed a thick circular part (7) having a thickness proportional to the voltage applied to the electrodes 5 and 6 according to the relation (1):

[0035] V d 3 ·...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com