Multi-stage evaporation micro-channel heat pipe heat transferring and radiating device

A technology of micro-channel heat pipe and heat dissipation device, which is applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of affecting the working performance of heat pipes, reducing heat transfer efficiency, drying of capillary structure, etc., and achieving excellent isothermal performance and temperature. controllability, increase the heat extraction area, and reduce the effect of thermal coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

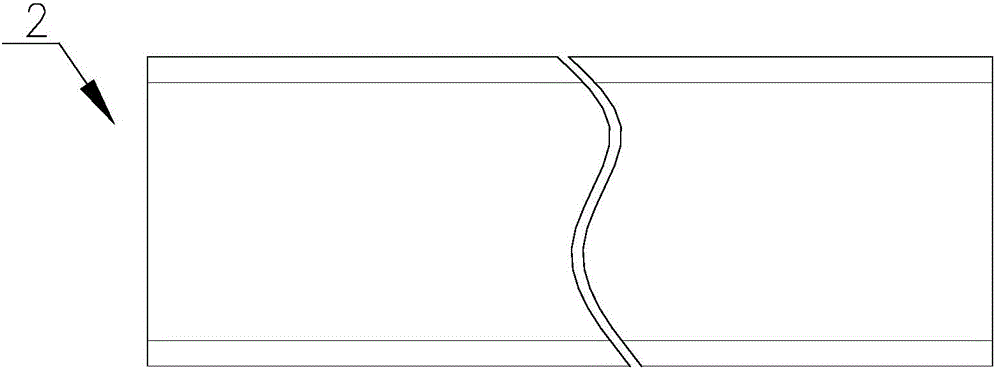

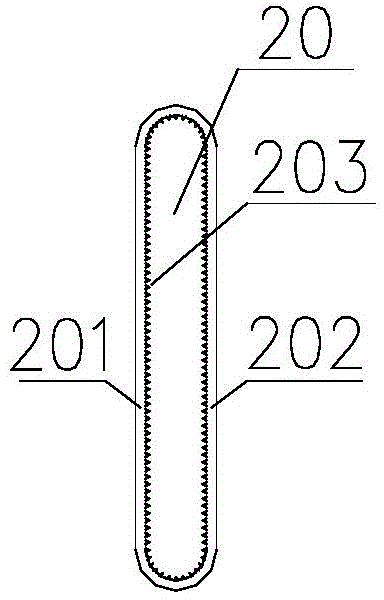

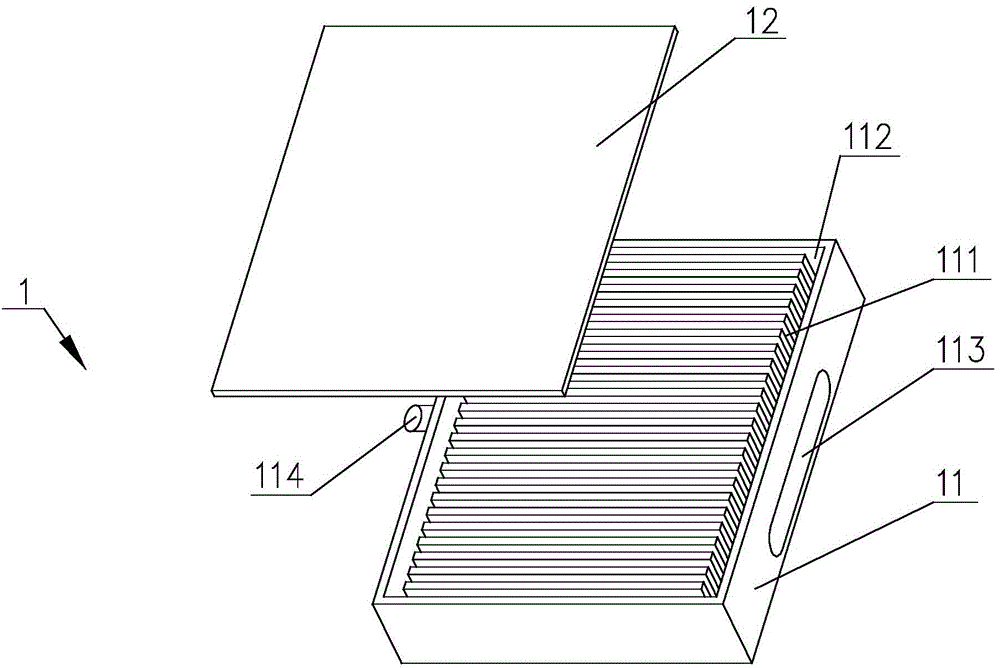

[0029] The heat dissipation device in this example is a two-stage evaporative heat transfer system, including two independent working fluid circulation systems composed of a heat absorption end and a heat dissipation end. In this example, the heat sink is composed of three heat sinks 1, which are respectively installed on the three heat sources. Each heat sink 1 is connected to the condenser 3 through a heat pipe 2, such as Figure 4 shown. The size of each heat sink 1 (indicating the number of microchannels included) is determined by the calorific value and heating area of the heat source. The larger the heat source, the larger the installed heat sink and the more microchannels it contains. Figure 5 The microchannel structure inside the condenser 3 is shown. According to the size of the three connected heat sinks 1, the condenser 3 in this example is divided into three parts of corresponding size, each part includes a number of microchannels 311, and the The number corre...

Embodiment 2

[0032] In the heat sink of this example, a heat transfer device is connected between the heat absorption end and the heat dissipation end. The structure of the heat transfer device is as follows: Figure 9 As shown, the condenser end 33 and the evaporation end 31 are included. The condenser end 33 and the evaporation end 31 have the same structure as the condenser 3. The microchannel structure inside the condenser end 33 and the evaporation end 31 can be referred to the structure of the condenser 3, which is also divided into three parts. Parts are connected by three heat pipes 2 to form three enclosed and independent working fluid circulation spaces, such as Figure 9 Shown in dashed line. The heat transfer device in this example also uses the phase change of the working medium to transfer heat. The connection structure between the transfer device and the heat absorption end and the heat dissipation end is as follows Figure 10 As shown, the evaporation end 31 is welded with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com