Impeller capable of increasing centrifugal pump noise tone quality and design method thereof

A technology of centrifugal pumps and impellers, which is applied to parts, pumps, and pump components of pumping devices for elastic fluids, and can solve problems such as the lack of consideration of the smooth distribution of noise spectrum, casting difficulties, and simple centrifugal pumps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

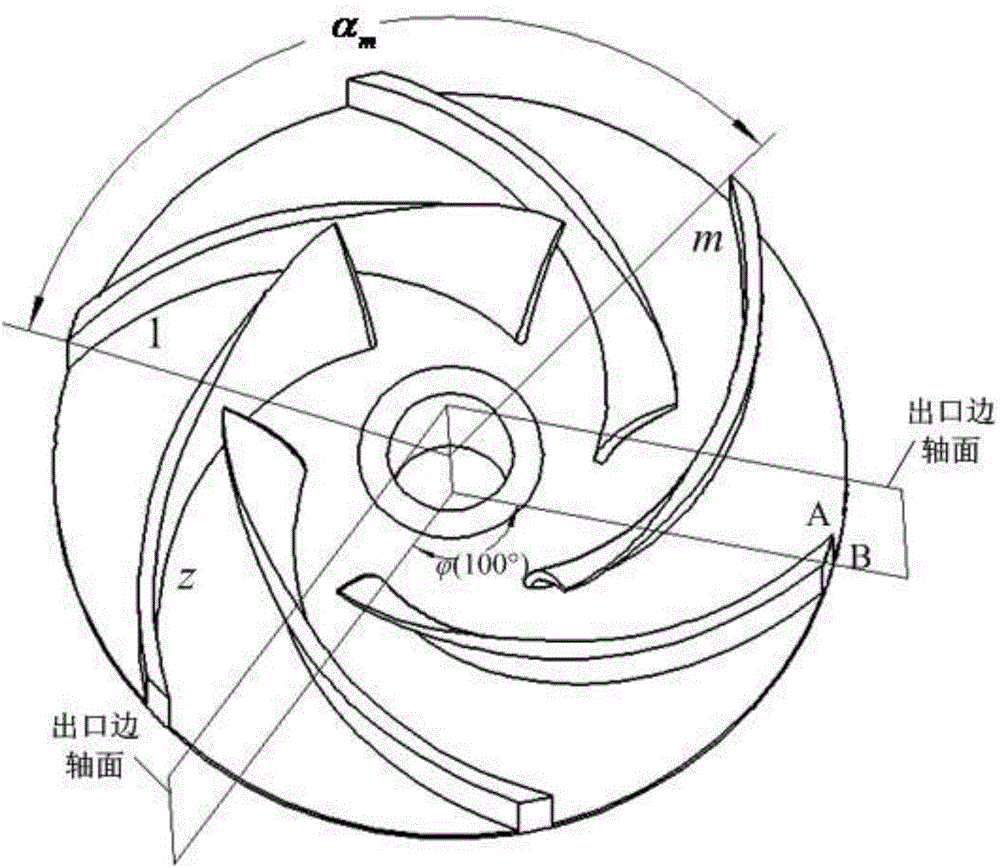

[0046] figure 1 It is a schematic diagram of the original impeller, which is used in the embodiments for detailed description.

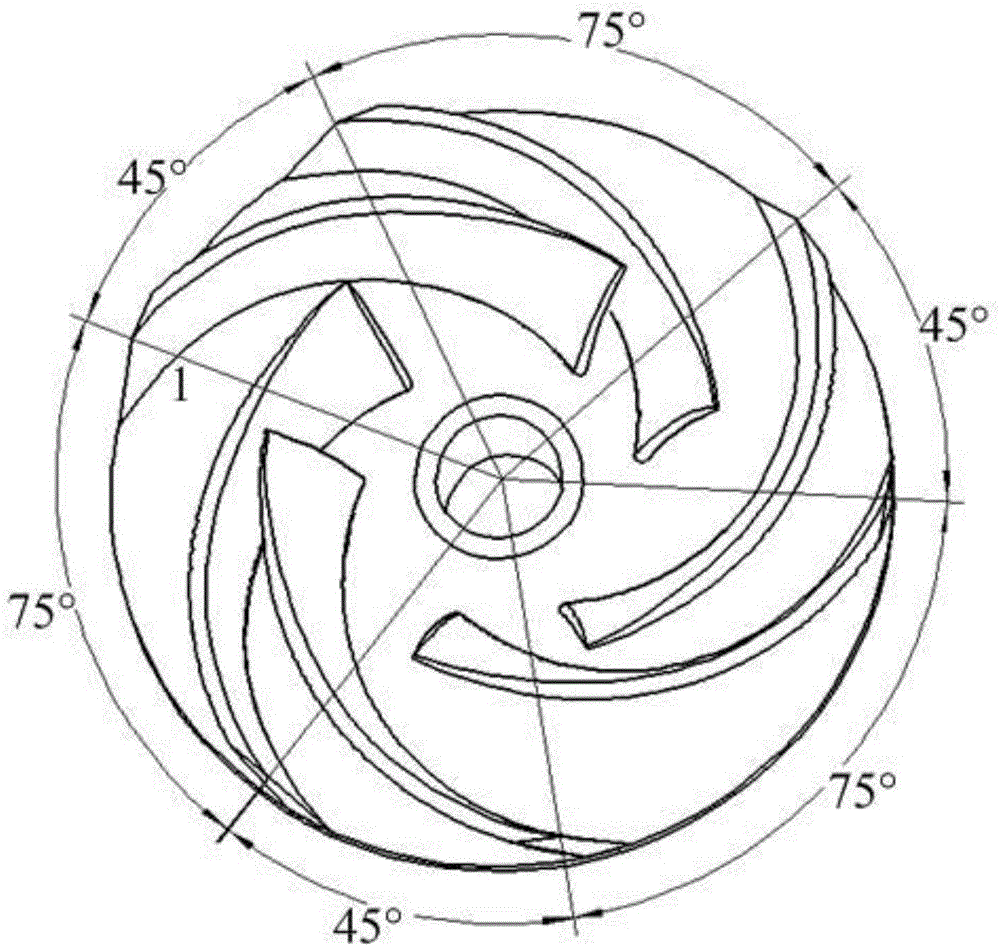

[0047] (1) The number of blades obtained by measuring the original impeller is 6, and the position of one blade 1 is used as a reference, that is, the position of blade 1 is fixed, so that the number of blades that can optimize the modulation pitch is reduced to 5 blades.

[0048] (2) The automatic balance theory is used to constrain the rotor blade spacing arrangement, and the constraint equation is:

[0049] Σ m = 1 6 cos α m = 0 , Σ m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com