Straight Shaft Pump

A water pump and straight cylinder technology, applied in the field of straight cylinder axial water pumps, can solve the problems of not completely independent space between the stator inner cavity and the stator winding, limited scope of application, complex supporting machinery, etc., achieve obvious energy saving effect, less auxiliary machinery, and small volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

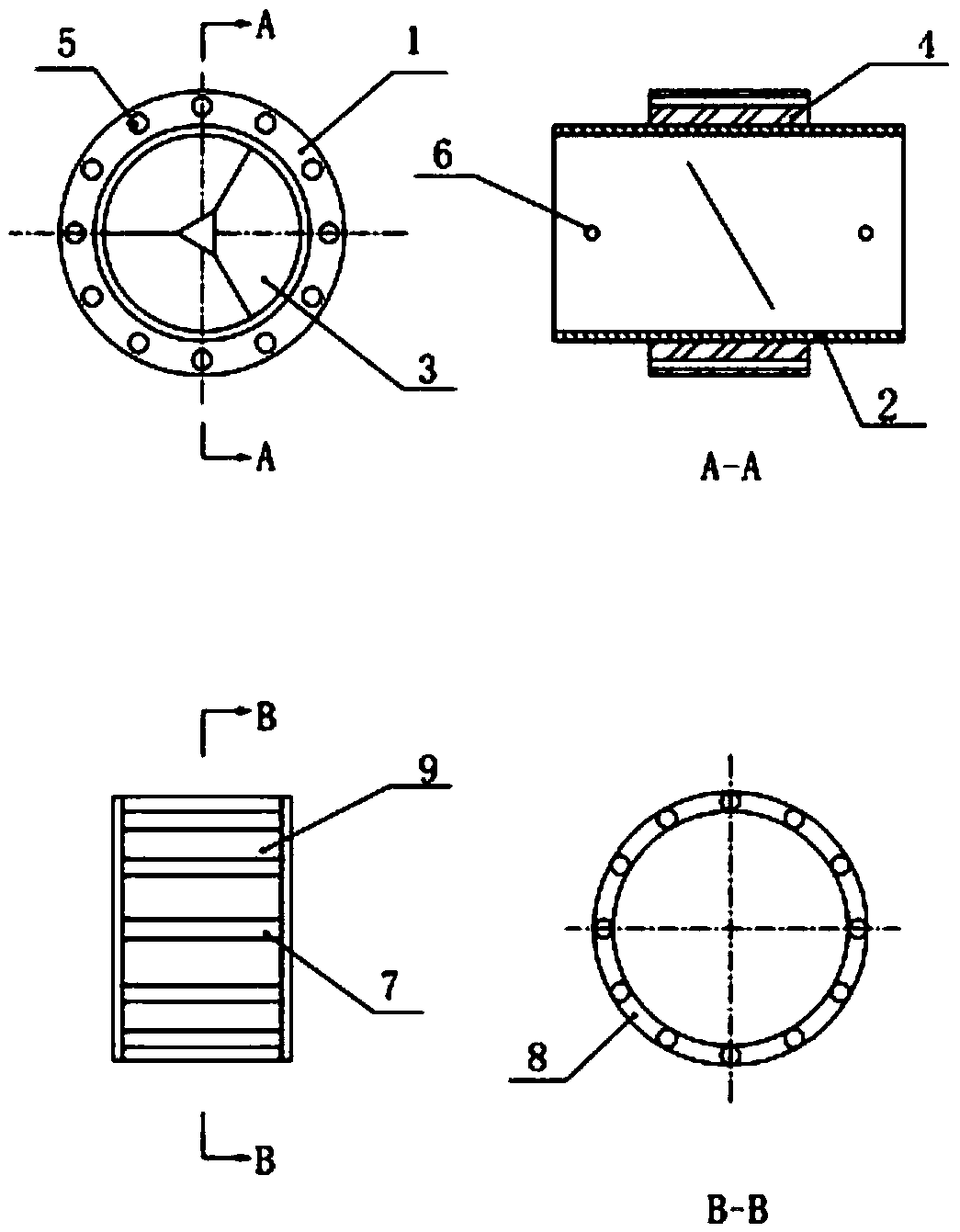

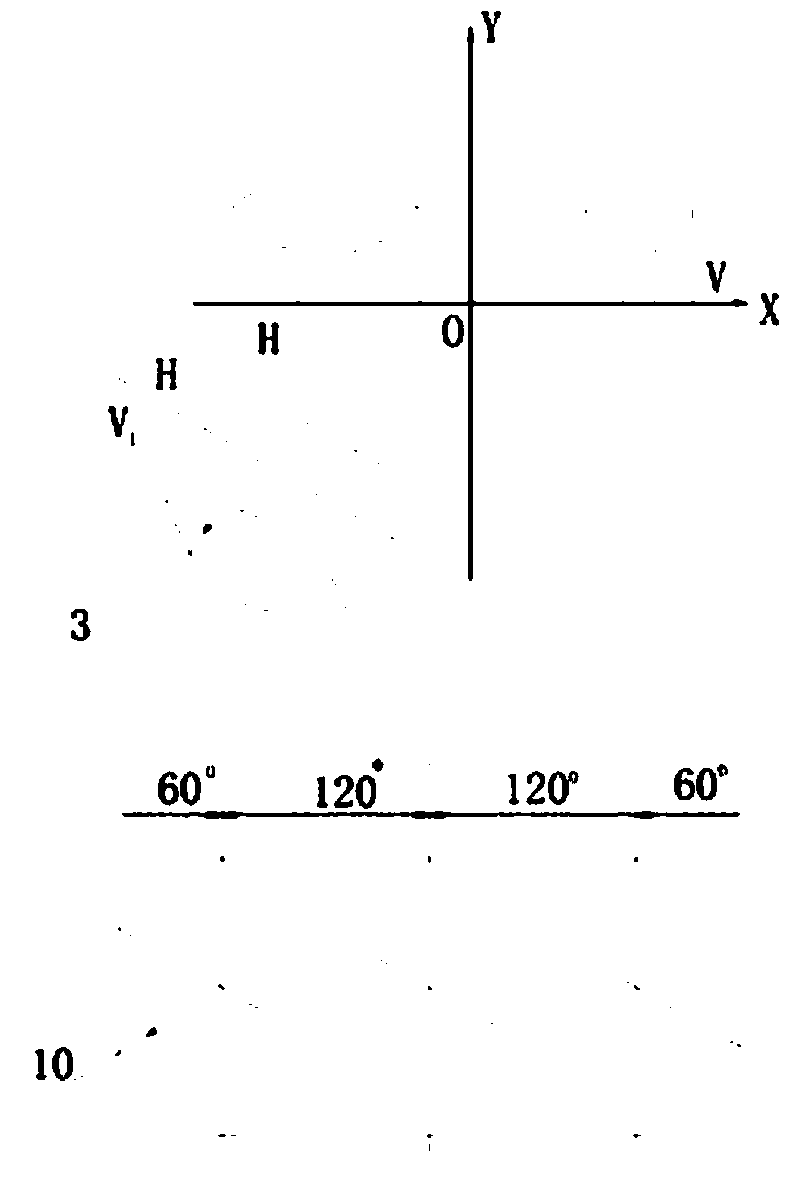

[0024] exist figure 1 , install three blades (3) with the same shape and size on the inner wall of the straight shaft (2) according to the position shown in (10), and then install the rotor core (4) made of silicon steel sheets on the straight shaft ( 2) On the outer wall of the rotor, install the copper guide bar (7) of the rotor winding (9) in the rotor slot (5), and install the copper end ring (8) and the copper guide bar at both ends of the rotor core (4). Bars (7) are connected, and a pair of symmetrical temperature adjustment holes (6) are respectively opened on both sides of the rotor iron core (4) on the straight rotor shaft (2) to form the motor rotor (impeller) (1).

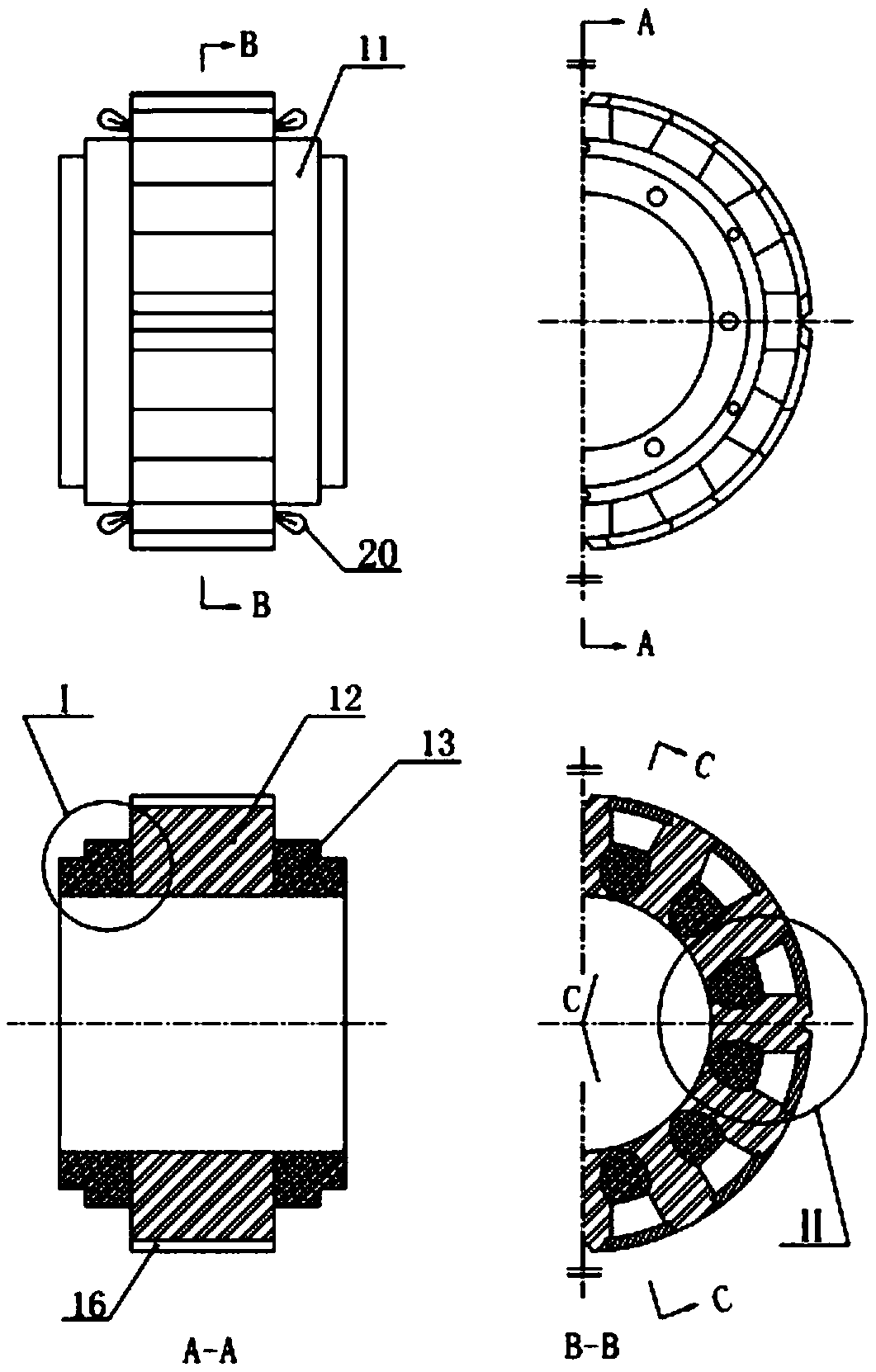

[0025] exist image 3In the shown embodiment, the silicon steel sheet is punched according to the shape of the stator core pole (12), laminated and fixed to form the stator core pole (12), and installed in the stator core fixture (21), the inner diameter Leave a certain gap (17) between the magnetic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com