Acidic copper chloride etching liquid electrolytic regeneration recycling and copper plate recovery device and method

An electrolytic regeneration and recovery device technology, which is applied in the direction of photographic technology, equipment, and photographic auxiliary technology, can solve the problems of high energy consumption, high content of cathode copper impurities, low recycling rate, etc., and achieve low energy consumption, uniform current distribution, The effect of high reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

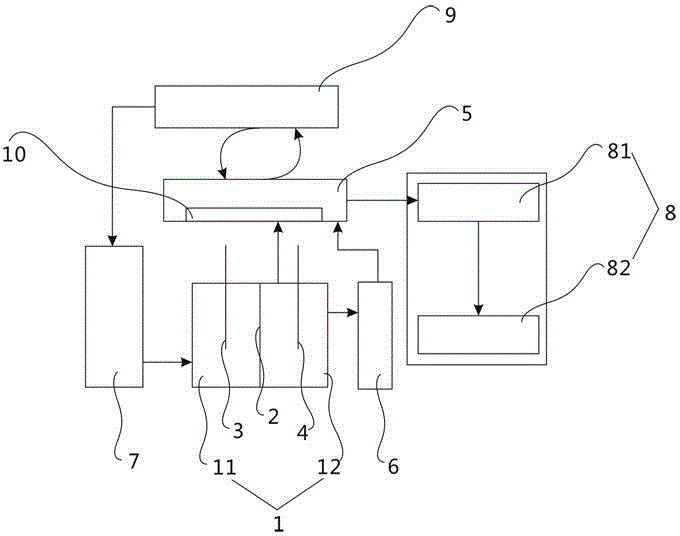

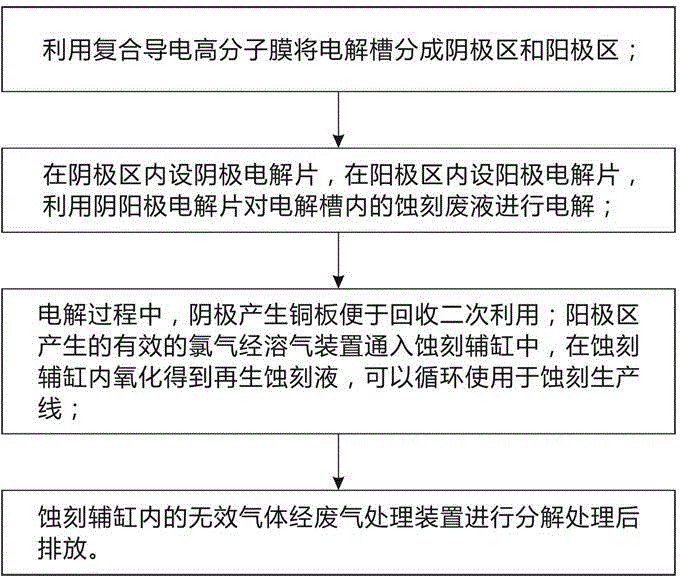

[0036] refer to figure 1 , The acidic copper chloride etching solution electrolytic regeneration cycle and copper plate recovery device of the present invention include a composite conductive polymer film electrolytic cell 1, an etching auxiliary cylinder 5, an etching waste liquid collection cylinder 7, a regeneration liquid collection cylinder 6, and a waste gas treatment device 8. The composite conductive polymer film 2 divides the electrolytic cell 1 into a cathode area 11 and an anode area 12. The cathode area 11 is provided with a cathode electrolysis sheet 3, the anode area 12 is provided with an anode electrolysis sheet 4, and the etching auxiliary cylinder 5 is provided with a dissolved gas Device 10; the waste liquid produced by the etching cylinder 9 is sent to the cathode area 11 of the electrolytic ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com