Method for manufacturing hard plastic bridge frame with waste plastic

A technology for rigid plastics and waste plastics, applied in the field of processing rigid plastic bridges, can solve the problems of poor use effect, large amount of formula addition and high production cost, and achieve the effects of improved strength, good flame retardant performance and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] A method for processing rigid plastic bridge frames using waste plastics, the preparation method is:

[0022] (1) Wash the waste plastic with a plastic cleaning agent and filter it in clean water for 10 minutes. Put the washed waste plastic in a dryer for 10 minutes at a drying temperature of 100°C;

[0023] (2) The waste plastics after cleaning and drying in step (1) are cut into 20*20cm pieces with a cutting machine and then added to the crusher to be broken into waste plastic particles with a diameter of 0.5mm, and then the waste plastic particles are added to the mill Grind in the powder machine into waste plastic powder with a particle size of 50 mesh;

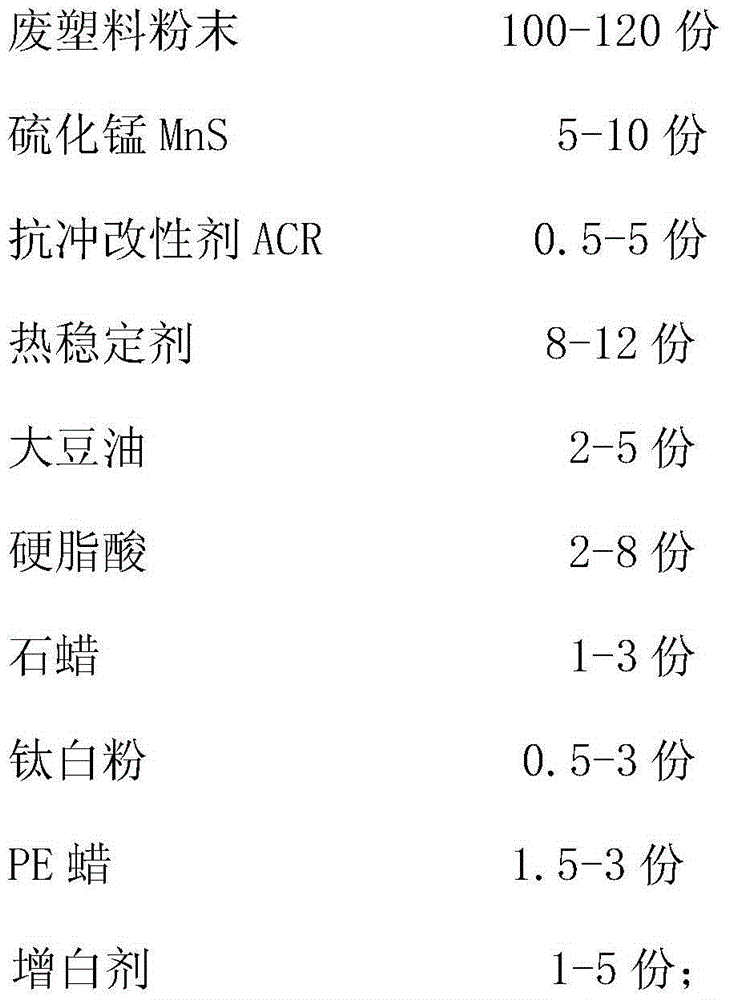

[0024] (3) Methyl tin mercaptan, calcium laurate, calcium zinc stabilizer, and propylene oxide are mixed uniformly with heat stabilizer in a weight ratio of 2:3.5:1.8:1.2, and 100 parts of waste plastic powder, manganese sulfide Add 6 parts of MnS, 1.5 parts of impact modifier ACR, 9 parts of heat stabilizer, 2.5 parts o...

example 2

[0027] A method for processing rigid plastic bridge frames using waste plastics, the preparation method is:

[0028] (1) Wash the waste plastic with a plastic cleaning agent and filter it in clean water for 10 minutes. Put the cleaned waste plastic in a dryer for 10 minutes at a drying temperature of 110°C;

[0029] (2) The waste plastics after cleaning and drying in step (1) are cut into 15*15cm pieces with a cutting machine, and then added to the crusher to be broken into waste plastic particles with a diameter of 0.1mm, and then the waste plastic particles are added to the mill Grind in the powder machine into waste plastic powder with a particle size of 30 mesh;

[0030] (3)Mix methyl tin mercaptide, calcium laurate, calcium zinc stabilizer in a weight fraction ratio of 2:2.5:1.6 to mix uniform heat stabilizer, 120 parts of waste plastic powder, 5.5 parts of manganese sulfide MnS, impact resistance 0.8 parts of modifier ACR, 10 parts of heat stabilizer, 3 parts of soybean oil, 5...

example 3

[0033] A method for processing rigid plastic bridge frames using waste plastics, the preparation method is:

[0034] (1) Wash the waste plastic with a plastic cleaning agent and filter it in clean water for 10 minutes. Put the cleaned waste plastic in a dryer for 10 minutes at a drying temperature of 110°C;

[0035] (2) The waste plastics after cleaning and drying in step (1) are cut into 15*15cm pieces with a cutting machine, and then added to the crusher to be broken into waste plastic particles with a diameter of 0.1mm, and then the waste plastic particles are added to the mill Grind in the powder machine into waste plastic powder with a particle size of 30 mesh;

[0036] (3) 110 parts of waste plastic powder, 6 parts of manganese sulfide MnS, 1.3 parts of impact modifier ACR, 9 parts of calcium and zinc stabilizer, 3 parts of soybean oil, 4.8 parts of stearic acid, 1.2 parts of paraffin, 1.5 parts of titanium dioxide Part, PE wax 1.8 parts, and whitening agent 1.5 parts are adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com