Preparation method for particle diameter controllable millimeter-scale polyurea monodisperse microsphere

A monodisperse microsphere, millimeter-scale technology, applied in the field of preparing polymer monodisperse microspheres and millimeter-scale polyurea monodisperse microspheres, can solve the problems of complex post-processing process, low monomer conversion rate and high production cost, To achieve the effect of simple post-processing steps, simple post-processing process, low production cost and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Add 400 g of 0.1% ethylenediamine aqueous solution (liquid level height 10 cm, the same below) into a 500 mL beaker with a height of 15 cm, and then place the beaker in a constant temperature water bath at 70 ° C until the system temperature is constant at 70 ° C , use a syringe pump to drop 20mL of toluene diisocyanate monomer into the ethylenediamine aqueous solution at a rate of 130mL / h through a needle with an inner diameter of 250μm, and continue to keep warm for 4h after the addition is completed. Then the product was filtered and dried in an oven at 80° C. for 10 h to obtain the polyurea microsphere product.

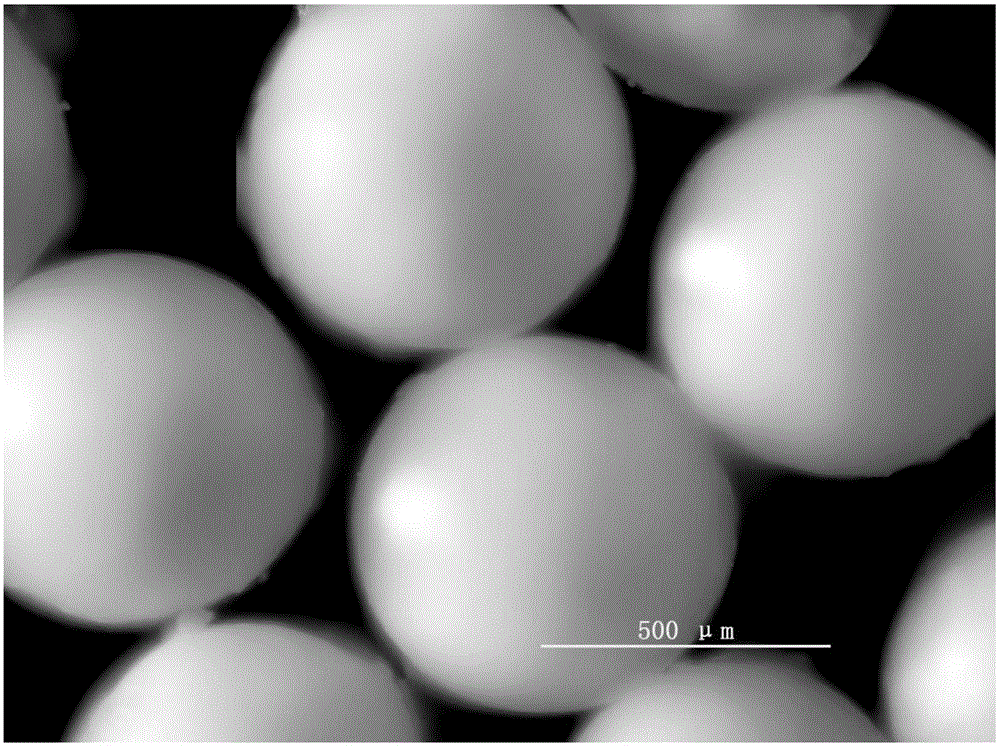

[0046] The average particle size of the obtained polyurea microspheres is 0.66mm, the particle size polydispersity coefficient is 1.011, and the specific surface is 118.68m 2 / g, the porosity is 48.2%, and its scanning electron micrograph is as follows figure 1 As shown, the microsphere cross-sectional scanning electron micrograph ( figure 2 ) shows tha...

Embodiment 2

[0048] Add 400 g of triethylenetetramine aqueous solution with a mass fraction of 0.1% to a 500 mL beaker with a height of 15 cm, and then place the beaker in a constant temperature water bath at 60 ° C. After the temperature is constant, use a syringe pump to inject 130 mL Add 20 mL of toluene diisocyanate monomer dropwise to the triethylenetetramine aqueous solution at a speed of 1 / h, and continue the heat preservation reaction for 3 h after the dropwise addition is completed. Then the product was filtered and dried in an oven at 80° C. for 10 h to obtain the polyurea microsphere product.

[0049] The average particle size of the obtained polyurea microspheres is 0.68mm, the particle size polydispersity coefficient is 1.008, and the specific surface is 109.56m 2 / g, the porosity is 45.5%, and the optical microscope photos of the microspheres are as follows image 3 shown.

Embodiment 3

[0051] Add 400g of distilled water to a 500mL beaker with a height of 15cm, and then place the beaker in a constant temperature water bath at 50°C. After the temperature is constant, use a syringe pump to drop into the water at a rate of 50mL / h 20mL of toluene diisocyanate monomer, after the dropwise addition, continue to keep warm for 3h. Then the product was filtered and dried in an oven at 80° C. for 10 h to obtain the polyurea microsphere product.

[0052] The average particle size of the obtained polyurea microspheres is 0.30mm, the particle size polydispersity coefficient is 1.005, and the specific surface is 149.83m 2 / g, the porosity is 57.3%, the infrared spectrum of the microspheres is as follows Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com