Preparation method of millimeter wave RF-MEMS (radio frequency-micro-electromechanical system) switch

A millimeter wave and switch technology is applied in the field of preparation of millimeter wave RF MEMS switches, which can solve the problems of low switch yield, short service life, low insertion loss and difficulty in realizing high isolation, and achieves the effect of a simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

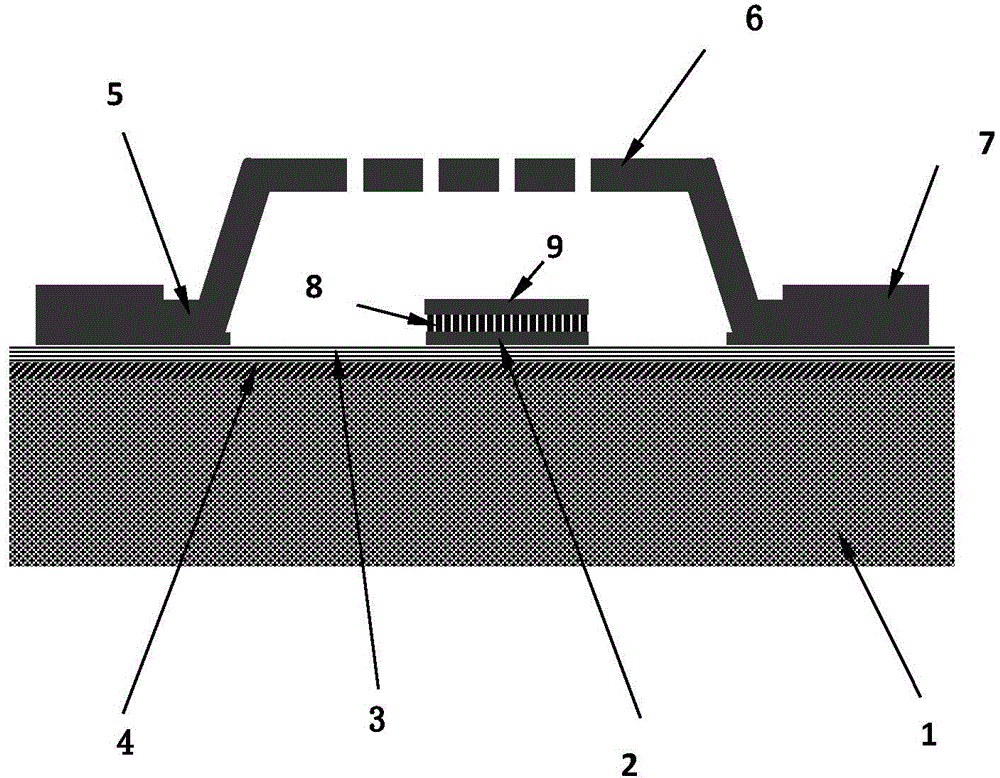

[0037] Below, combine figure 1 The present invention is further described.

[0038] A preparation method of a millimeter-wave RF MEMS switch, the millimeter-wave RF MEMS switch includes a switch substrate, a CPW pattern on the switch substrate and a thin film microbridge 6, the CPW pattern includes an RF transmission line 2 and is located on both sides of the RF transmission line The ground wire 7 specifically includes the following steps:

[0039] (1) On the surface of the high-resistance silicon wafer 1, a layer of polysilicon 4 is grown by PECVD process, and then a layer of silicon dioxide 3 is grown on the polysilicon to obtain a switch substrate;

[0040] (2) cleaning and drying the silicon wafer after step (1);

[0041] (3) Send the silicon chip after step (2) into the magnetron sputtering station, and sputter the titanium-tungsten-gold film layer;

[0042] (4) take out the silicon chip after step (3) processing, cover the position other than the line pattern that nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com