Welded joint of intercommunicating liquid-cooled rack and manufacturing method thereof

A technology for welding joints and liquid cooling racks, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problem of low welding qualification rate of rack or chassis, remelting of cold plate brazing seam, and limited welding space and other problems, to achieve the effect of simple structure, good welding seam sealing and high qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

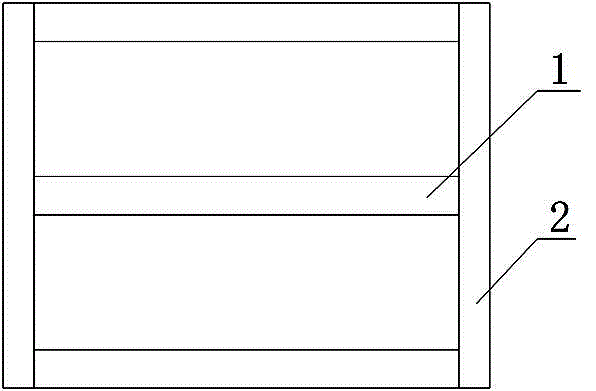

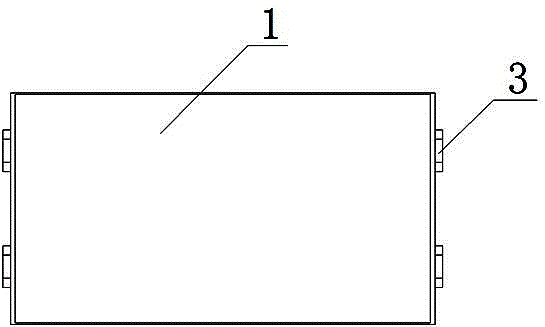

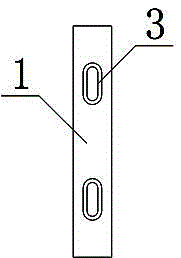

[0034] Such as figure 1 As shown, a welded joint of an intercommunicating liquid-cooled rack includes a welding cold plate 1 and a connecting cold plate 2, such as figure 2 As shown, the two sides of the welding cold plate 1 are respectively provided with at least two tenons 3, such as image 3 As shown, tenon 3 is a hollow structure, such as Figure 4 and Figure 5 As shown, the connecting cold plate 2 is provided with a vertically downward groove 4, and the bottom of the groove 4 is provided with a plurality of mortises 5 consistent with the number of the welded cold plate 1. 3 are matched, and there is a cover plate groove 6 along the side wall of the groove 4, and a cold plate cover plate is installed in the cover plate groove 6; the welded cold plate 1 is horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com