Metal ion-doped titanium dioxide plate-type photocatalytic microreactor and preparation method for catalyst thin films in reactor

A technology of metal ions and titanium dioxide, applied in the field of photocatalysis, can solve problems such as difficult engineering problems, low processing capacity of a single microchannel, inconsistent surface in the propagation direction, etc., and achieve low cost, increase raw material processing capacity, and simple parallel amplification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention has the preparation method of catalyst thin film in the titania plate type photocatalytic microreactor of metal ion doping, and it comprises the following steps:

[0048] Step 1: Prepare the sol-gel solution, the specific steps are:

[0049] (a) Add butyl titanate, absolute ethanol and diethanolamine in sequence in the reactor, and electromagnetically stir until the mixture reaches a clear and transparent state, wherein the molar ratio of butyl titanate, absolute ethanol and diethanolamine is 1: (4-6):(1-8);

[0050] (b) add absolute ethanol, distilled water and metal soluble salt in the container successively to completely dissolve the metal soluble salt to form a metal soluble salt solution, wherein absolute ethanol, distilled water and metal soluble salt are added with butyl titanate in step (a) The molar ratio of amount is (2-4):(1-10):(0.0001-0.005):1; The preferred metal ion of doping is La 3+ 、Cu 2+ , Mn 2+ , Fe 3+ , Zn 2+ or Ni 2+ On...

Embodiment 1

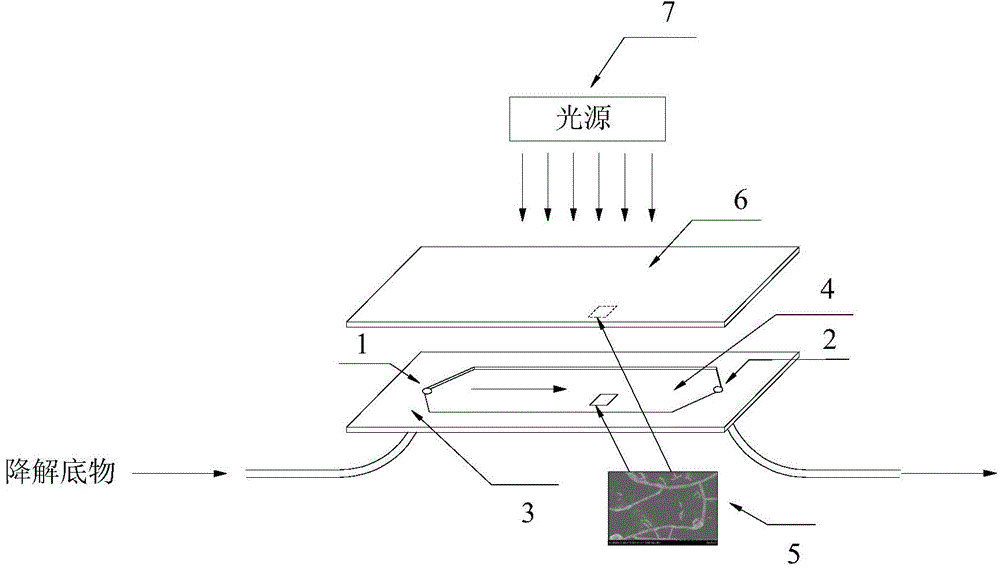

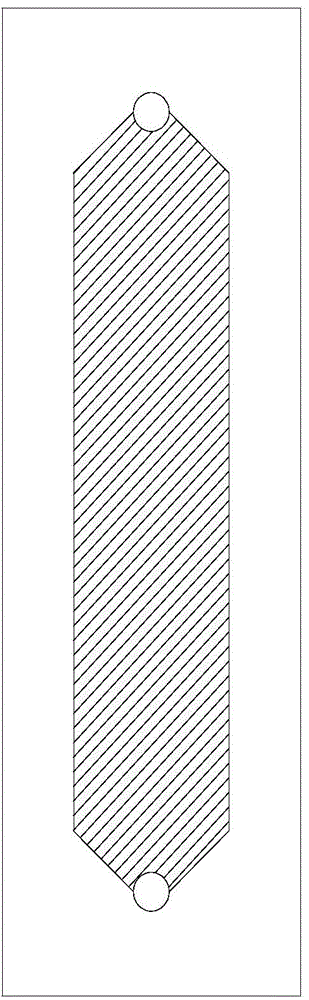

[0056] In the first step, a single-channel groove reaction area is formed on a stainless steel plate by chemical etching. The width of the groove is 15 mm, and the depth is 300 μm. An inlet 1 and an outlet 2 respectively connected to the inlet and outlet of the single-channel reaction area are opened on the stainless steel plate base;

[0057] In the second step, TiO doped with metal ions was prepared by sol-gel method 2 Sol-gel.

[0058] (a) Add butyl titanate, absolute ethanol and diethanolamine in sequence in the reactor, and electromagnetically stir until the mixture reaches a clear and transparent state, wherein the molar ratio of butyl titanate, absolute ethanol and diethanolamine is 1: 4:5;

[0059](b) add absolute ethanol, distilled water and metal soluble salt in the container successively, make metal soluble salt dissolve completely and form metal soluble salt solution, wherein absolute alcohol, distilled water and metal soluble salt are mixed with butyl titanate i...

Embodiment 2

[0069] Preparation of the single channel reactor of the present invention:

[0070] In the first step, a single-channel grooved reaction area is formed on a stainless steel plate by electrocorrosion. The width of the groove is 20 mm, and the depth is 250 μm. On the base of the stainless steel plate, an inlet 1 and an outlet 2 respectively connected with the inlet and outlet of the single-channel reaction area are opened, the area of the channel wall, the area of the inner bottom of the channel, and the area of the catalyst. Coating area, reaction volume, and specific surface area parameters are as follows: 26mm 2 , 727mm 2 , 753mm 2 , 0.15mL, 5.18mm 2 / mm 3 ;

[0071] In the second step, Cu 2+ Doped TiO 2 Sol-gel.

[0072] (a) Add butyl titanate, absolute ethanol and diethanolamine in sequence in the reactor, and electromagnetically stir until the mixture reaches a clear and transparent state, wherein the molar ratio of butyl titanate, absolute ethanol and dietha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com