Wafer silicon through hole structure and preparation method thereof

A technology of through-silicon vias and wafers, applied in the field of microelectronics, can solve the problems of limited space for increasing the thickness of silicon dioxide insulating layer, expensive high-resistance silicon, slow oxidation speed, etc., so as to weaken the electric field density and reduce the effective contact , the effect of reducing the thermal stress effect

Active Publication Date: 2014-11-12

NAT CENT FOR ADVANCED PACKAGING

View PDF3 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

High-resistance silicon is more expensive, and it is only suitable for 2.5D silicon adapter boards, not for 3D active chip through-silicon vias

The space for increasing the thickness of the silicon dioxide insulating layer is limited. For thermally oxidized silicon dioxide, the oxidation rate is very slow after the thickness is greater than 1 micron. The increase in the thickness of silicon dioxide grown by PECVD will cause stress and cracking problems.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

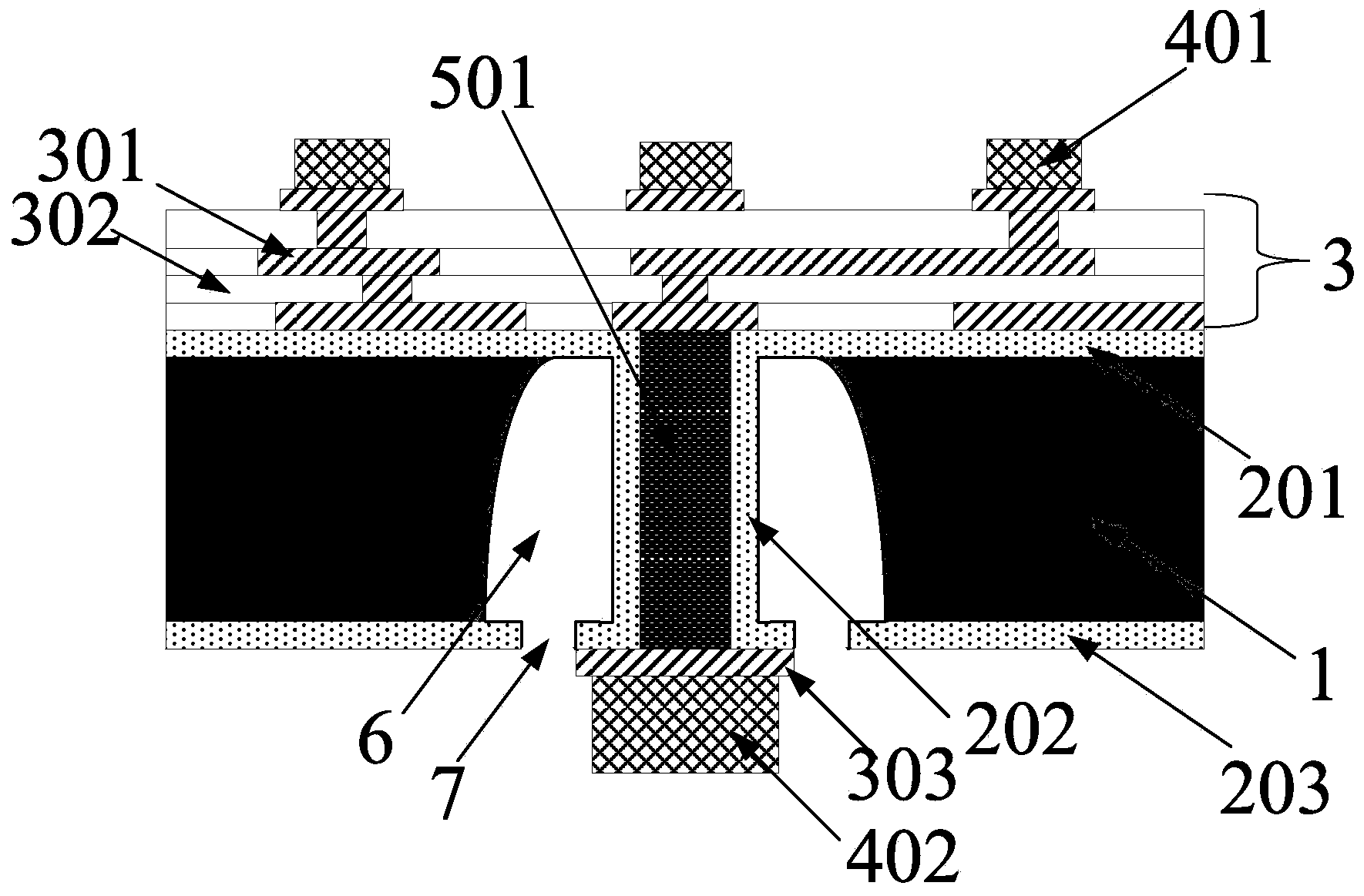

The invention belongs to the field of micro electronic techniques and discloses a wafer silicon through hole structure. The wafer silicon through hole structure comprises a through hole, a front passivation layer, a through hole passivation layer, a back passivation layer and a cavity in the periphery of the through hole passivation layer. The through hole is formed in a silicon substrate of a wafer, the through hole passivation layer is arranged on the lateral wall in the through hole, the front passivation layer and the back passivation layer are arranged on the front face and the back face of the silicon substrate and are respectively connected with the through hole passivation layer, and the cavity is formed in the periphery of the through hole passivation layer and in the silicon substrate. The thermal stress effect caused by large difference between coefficients of thermal expansion of through hole metal and silicon materials is reduced by forming the cavity outside the through hole in the wafer silicon substrate. Meanwhile, electric field density of the periphery of the through hole is greatly reduced so as to reduce high frequency loss of the through hole.

Description

technical field The invention relates to the technical field of microelectronics, in particular to a wafer through-silicon hole structure. Background technique With the consumer market's increasing demand for electronic products with small size, multi-function, low power consumption, and high performance, planar integrated circuits are facing huge challenges, and the feature size of CMOS is gradually approaching the physical limit. "Ultramole", 2.5-dimensional and 3-dimensional integration technology based on through-silicon via (Throuth-silicon-Via TSV) is expected to become a new driving force for the development of electronic integration technology. The structural design, fabrication process, physical parameter extraction and modeling of TSVs have become research hotspots. Since silicon is a semiconductor material with a forbidden band width of only 1.12eV, even intrinsic silicon has a certain degree of conductivity at room temperature, and in actual use, it usually pre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L23/528H01L21/768

Inventor 李宝霞

Owner NAT CENT FOR ADVANCED PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com