Semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, which are used in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of high substrate cost, difficult threshold voltage control, and inability to meet the breakdown voltage requirements of different devices at the same time. , to achieve the effect of increasing the breakdown voltage and reducing the electric field density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

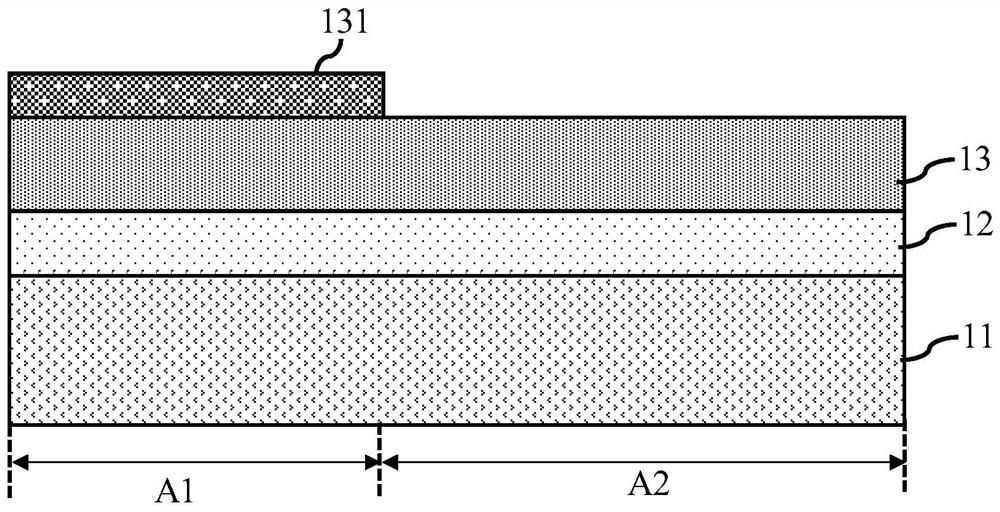

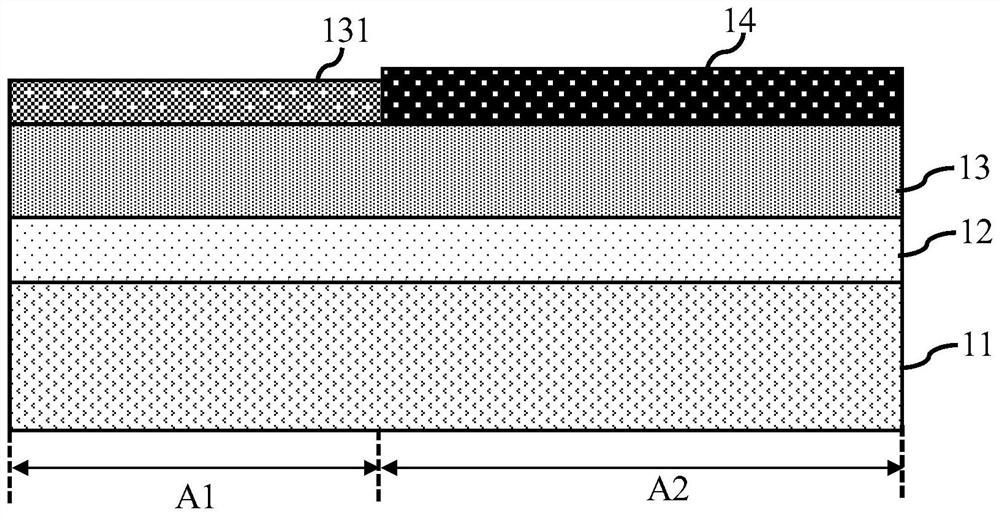

[0049] In order to make the purpose, advantages and features of the present invention clearer, the semiconductor device and its manufacturing method proposed by the present invention will be further described in detail below with reference to the accompanying drawings. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

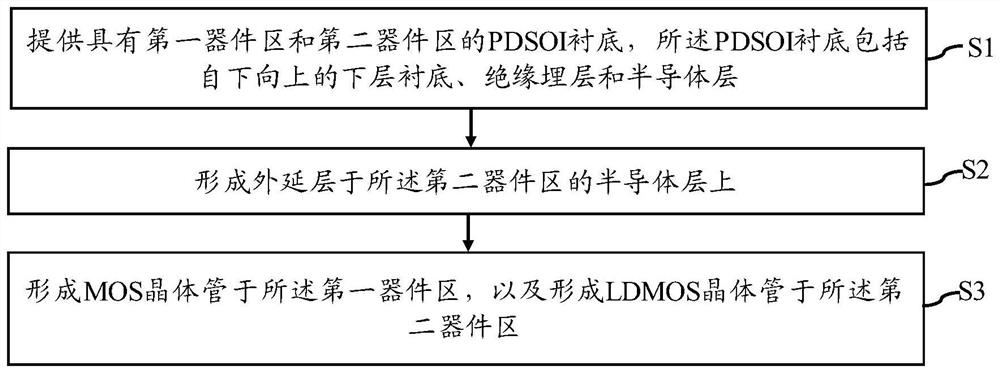

[0050] An embodiment of the present invention provides a method for manufacturing a semiconductor device, see figure 1 , figure 1 It is a flowchart of a method for manufacturing a semiconductor device according to an embodiment of the present invention, and the method for manufacturing a semiconductor device includes:

[0051] Step S1, providing a PDSOI substrate having a first device region and a second device region, the PDSOI substrate comprising an underlying substrate, an insulating buried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com