Low-temperature dehydration method of tea oil

A low-temperature dehydration and camellia oil technology, applied in the direction of fat oil/fat refining, fat production, etc., to achieve the effects of sufficient liquid-solid contact, shortened dehydration time, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

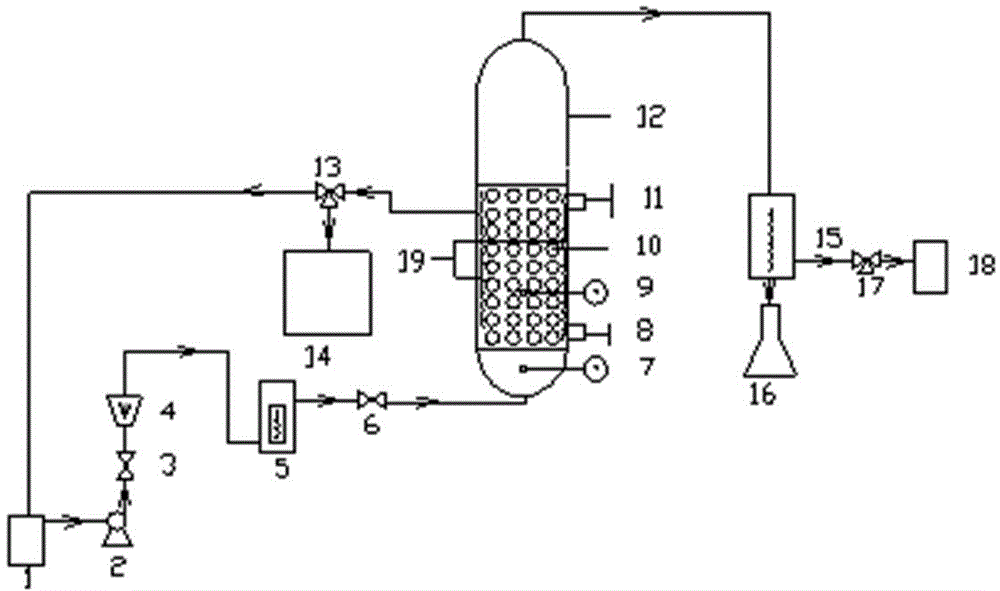

[0017] see figure 1 , the low-temperature dehydration of camellia oil concrete operation steps are as follows:

[0018] Step 1: Preparation of the molecular sieve bed: take 4A molecular sieve, put it into the distribution plate in the molecular sieve fluidized bed tower 12 from the molecular sieve inlet 11;

[0019] Step 2: Molecular sieve fluidized bed assisted negative pressure low-temperature dehydration: Put 50L of camellia seed crude oil pressed at low temperature to be dehydrated into the oil storage tank 1, adjust the first regulating valve 3, and transfer the oil through the oil pump 2 and the rotameter 4 The oil in the storage tank 1 is input into the first heater 5 and heated until the oil inlet thermometer 7 shows 45°C, the first regulating valve 3 and the second regulating valve 6 are adjusted, the second heater 19 is turned on, and the molecular sieve fluidized bed tower 12 is heated. The apparent fluidization liquid velocity of the oil is 1.5mm / s, the aspect rat...

Embodiment 2

[0022] Step 1: Preparation of the molecular sieve bed: take 5A molecular sieve, put it into the distribution plate in the molecular sieve fluidized bed tower 12 from the molecular sieve inlet 11;

[0023] Step 2: Negative-pressure low-temperature dehydration assisted by molecular sieve fluidized bed: put 30 L of washed oil of camellia oleifera seeds to be dehydrated into oil storage tank 1, adjust the first regulating valve 3, and pump oil storage tank 1 through oil pump 2 and rotameter 4 The oil input in the first heater 5 is heated until the oil inlet thermometer 7 shows 45°C, the first regulating valve 3 and the second regulating valve 6 are adjusted, and the second heater 19 is opened to make the oil in the molecular sieve fluidized bed tower 12 The apparent fluidized liquid velocity is 1.0 mm / s, the aspect ratio of the bed of molecular sieve 10 is 8:1, and the thermometer 9 at the bed mouth of the bed of molecular sieve 10 shows 60°C, then turn on the negative pressure pum...

Embodiment 3

[0026] Step 1: Preparation of the molecular sieve bed: take 4A molecular sieve, put it into the distribution plate in the molecular sieve fluidized bed tower 12 from the molecular sieve inlet 11;

[0027] Step 2: Molecular sieve fluidized bed assisted negative pressure low-temperature dehydration: Put 30L of tea seed crude oil pressed at low temperature to be dehydrated into the oil storage tank 1, adjust the first regulating valve 3, and transfer the oil through the oil pump 2 and the rotameter 4 The oil in the storage tank 1 is input into the first heater 5 and heated until the oil inlet thermometer 7 shows 45°C, the first regulating valve 3 and the second regulating valve 6 are adjusted, the second heater 19 is turned on, and the molecular sieve fluidized bed tower 12 is heated. The apparent fluidization liquid velocity of the oil is 1.2mm / s, the aspect ratio of molecular sieve 10 bed is 5: 1, the bed mouth thermometer 9 of molecular sieve 10 bed shows 65 ℃, then open negati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com