Low-temperature cureable coating composition and article having cured coating thereof

A curing and composition technology, applied in the direction of coating, etc., can solve the problems of isocyanate instability, poor adhesion, skin irritation, etc., achieve good adhesion, maintain alkali resistance, and eliminate hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

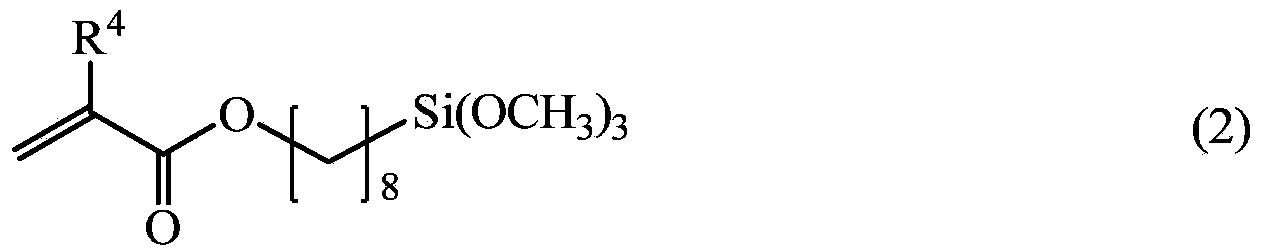

[0100] Providing methyl methacrylate as the alkyl (meth)acrylate (a1) and 8-methacryloxyoctyltrimethoxysilane as the silane compound having a hydrolyzable functional group and a radically polymerizable unsaturated group (a2). They were dissolved in methyl isobutyl ketone at a molar ratio a1 / a2 of 50 / 50 to form a monomer mixed solution. A solution of 2,2'-azobis(2-methylbutyronitrile) in methyl isobutyl ketone was added dropwise to the monomer mixed solution at 90°C. The reaction solution was aged at 90°C for 2 hours and then passed through a mesh filter. The corresponding hydrolyzable silyl group-containing (meth)acrylic copolymer was obtained as a solution in methyl isobutyl ketone with a non-volatile content of 25%.

[0101] Next, 100 parts by weight of a hydrolyzable silyl-containing (meth)acrylic copolymer (corresponding to the solid or non-volatile content of the copolymer solution) and 5 parts by weight of tetrabutyl orthotitanate as an organometallic catalyst were mix...

Embodiment 2

[0103] Except for using di-n-butoxy(ethyl acetoacetate)aluminum as the organometallic catalyst, the same procedure as in Example 1 (including the mixing ratio and base material) was repeated. Coatings were similarly evaluated.

Embodiment 3

[0105] Except for using 11-methacryloyloxyundecyltrimethoxysilane as the silane compound (a2), the same procedure as in Example 1 (including the mixing ratio and base material) was repeated. Coatings were similarly evaluated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com