Method for separating different sizes of alpha aluminum oxide nano-particles

A technology of α-alumina and nano-particles, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of difficult particle separation, easy introduction of impurities, complicated operation, etc., and achieve easy recycling and simple methods , the effect of high repetition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

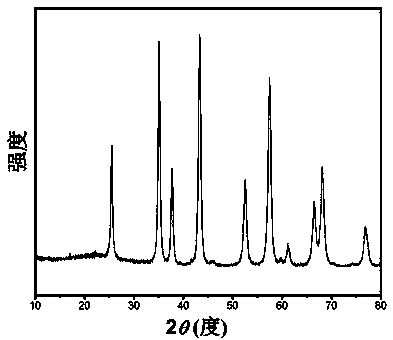

[0027] Weighing α-Al obtained by high energy ball milling method with electronic balance 2 o 3 For 0.4 g of nanoparticle powder, use a 10 mL graduated cylinder to take 4 mL of 1.25 M hydrochloric acid solution, put it into a centrifuge tube, and disperse the weighed alumina powder into it, and sonicate for 0.5 h. After sonication, centrifuge at 10,000 rpm for 5 min. Use a straw to draw the supernatant into another centrifuge tube, and adjust its concentration to 4.0 M with concentrated hydrochloric acid. It can be found that the originally clear solution has turned into a white emulsion, and then continue to centrifuge the white emulsion at 15,000 rpm for 5 min After centrifugation, suck out the supernatant with a pipette, and the precipitate in the centrifuge tube is the first step of separating the product.

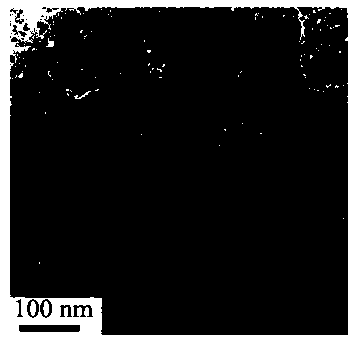

[0028] pass image 3 It can be seen from the TEM photos that the size distribution of the α-alumina nanoparticles separated in the first step is very uniform, the s...

Embodiment 2

[0030] Take 4 mL of 0.75 M hydrochloric acid solution in a 10 mL graduated cylinder, and disperse the precipitate obtained by centrifuging at 10,000 rpm for 5 min in Example 1 into it, and ultrasonicate for half an hour. The centrifuge tubes were then placed in a centrifuge and centrifuged at 10,000 rpm for 5 min. Use a straw to draw the supernatant into another centrifuge tube, and adjust its concentration to 4.0 M with concentrated hydrochloric acid. It can be found that the originally clear solution has turned into a white emulsion, and then continue to centrifuge the white emulsion at 15,000 rpm for 5 min After centrifugation, suck out the supernatant with a straw, and the precipitate in the centrifuge tube is the product of the second step of separation.

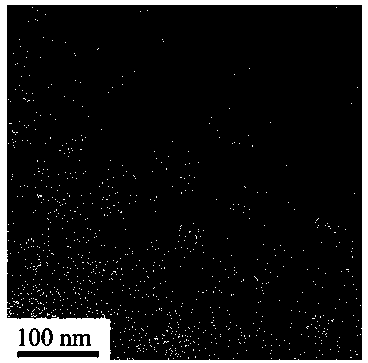

[0031] pass Figure 4 It can be seen from the TEM photos that the size distribution of α-alumina nanoparticles separated in the second step is mainly concentrated between 6.1-17.2 nm, and the average particle size is ...

Embodiment 3

[0033] Take 4 mL of 0.1 M hydrochloric acid solution in a 10 mL graduated cylinder, and disperse the precipitate obtained by centrifuging at 10,000 rpm for 5 min in Example 3 into it, and ultrasonicate for half an hour. The centrifuge tubes were then placed in a centrifuge and centrifuged at 10,000 rpm for 5 min. Use a straw to draw the supernatant into another centrifuge tube, and adjust its concentration to 4.0 M with concentrated hydrochloric acid. It can be found that the originally clear solution has turned into a white emulsion, and then continue to centrifuge the white emulsion at 15,000 rpm for 5 min After centrifugation, suck out the supernatant with a straw, and the precipitate in the centrifuge tube is the product of the third step separation.

[0034] pass Figure 5 It can be seen from the TEM photos that the size distribution of α-alumina nanoparticles separated in the third step is mainly concentrated between 8.8-30.7 nm, and the average particle size is 17.7 nm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com