Separation membrane support, method for manufacturing same, separation membrane using separation membrane support, and fluid separation device

A manufacturing method and technology for separation membranes, which are used in household components, chemical instruments and methods, semi-permeable membrane separation, etc., can solve problems such as peeling, and achieve excellent film-making properties, excellent processability, and small dimensional changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

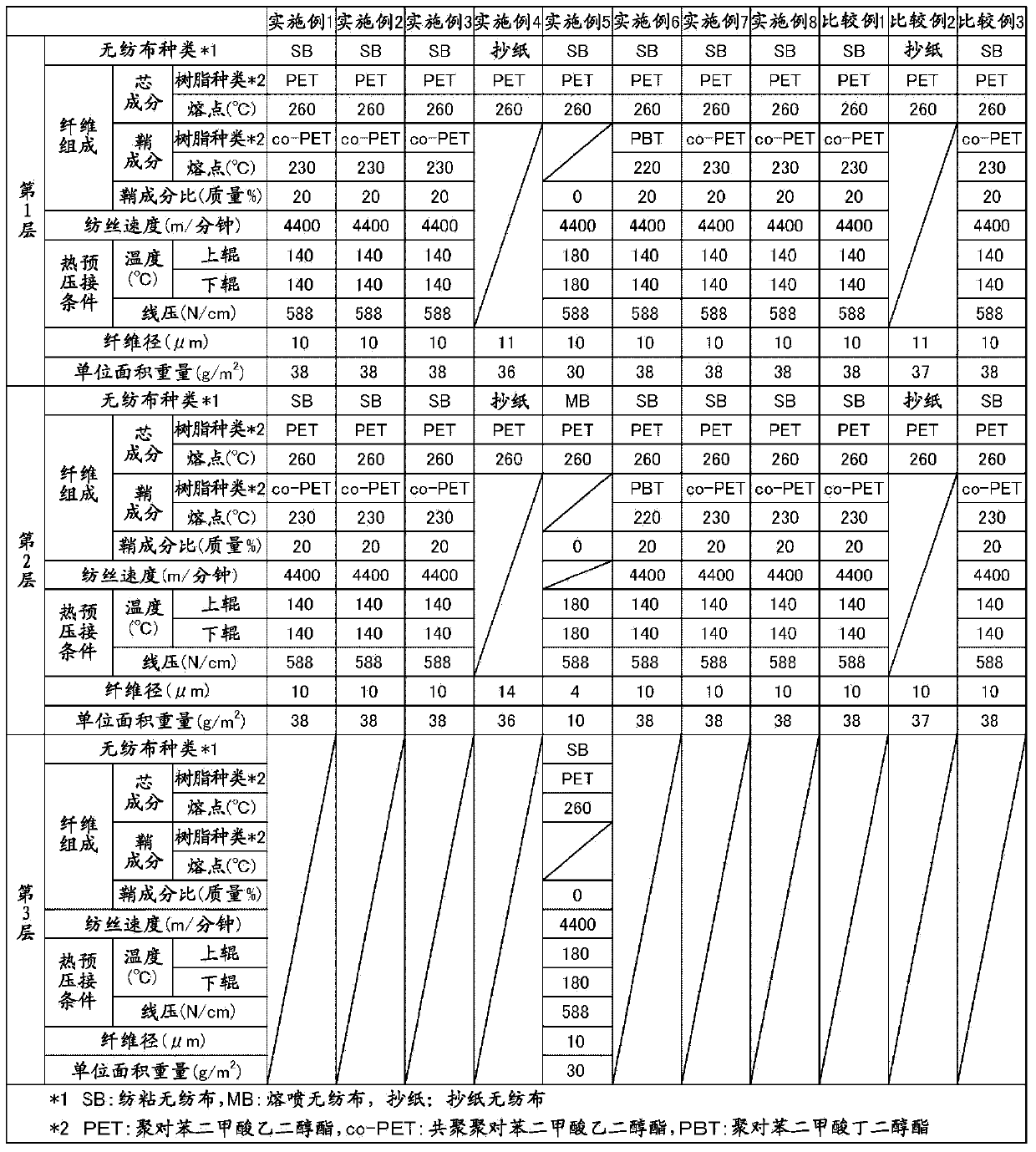

[0145] (core ingredient)

[0146] A polyethylene terephthalate resin having an intrinsic viscosity IV of 0.65, a melting point of 260° C., a titanium oxide content of 0.3% by mass, and dried to a moisture content of 10 ppm was used as a core component.

[0147] (sheath component)

[0148] A copolymerized polyethylene terephthalate resin having an intrinsic viscosity IV of 0.66, a copolymerization ratio of isophthalic acid of 11 mol%, a melting point of 230°C, a titanium oxide content of 0.2% by mass, and dried to a moisture content of 10 ppm was used as the sheath Element.

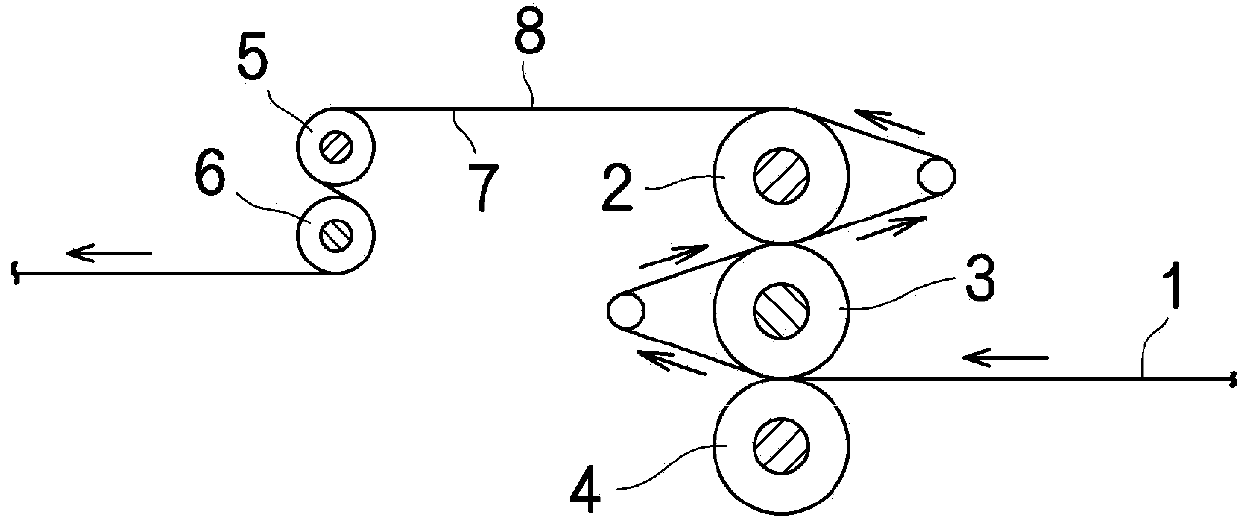

[0149] (Spinning and web capture)

[0150] The core component and the sheath component were melted at 295° C. and 270° C. respectively, and composited into a concentric core-sheath type (circular cross-section) with a die temperature of 300° C. and a core / sheath mass ratio of 80 / 20. The fine holes are spun out, and then spun through the ejector at a spinning speed of 4400m / min, and collected in the form...

Embodiment 2

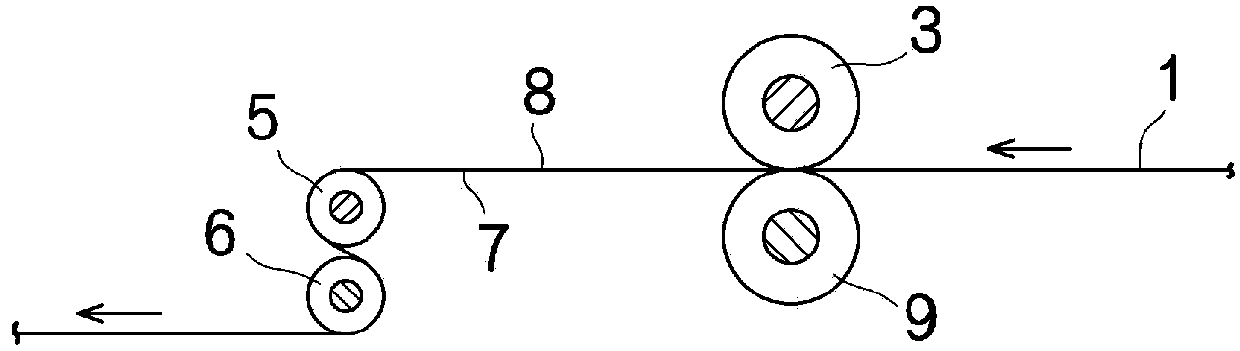

[0159] In the lamination thermocompression bonding, except that the speed ratio to the three flat rolls and the cooling roll was 1.02, a film with a basis weight of 76 g / m was manufactured in the same manner as in Example 1. 2 , a thickness of 0.09 mm, a boiling water shrinkage rate of 1.0% in the longitudinal direction, a water absorption time of 60 seconds or more, and a spun-bonded nonwoven fabric with a Becker smoothness of 14 seconds on the back to obtain a separation membrane support, and the separation membrane support A polysulfone membrane was produced in the same manner as in Example 1. At this time, the backside penetration of the casting liquid was not seen at all, and the length of the separation membrane formed / the length of the support rolled out was 0.995, and the membrane peel strength of the produced separation membrane was 44 cN / 15 mm. The results are shown in Table 1 and Table 2.

Embodiment 3

[0161] In the lamination thermocompression bonding, except that the surface temperature of the cooling roll was 90° C., and the speed ratio of the cooling roll to the three flat rolls was 1.02, it was produced in the same manner as in Example 1. m 2 , a thickness of 0.09 mm, a boiling water shrinkage rate of 1.8% in the longitudinal direction, a water absorption time of 60 seconds or more, and a spun-bonded nonwoven fabric with a Becker smoothness of 13 seconds on the back side to obtain a separation membrane support, on which the separation membrane support A polysulfone membrane was produced in the same manner as in Example 1 above. At this time, the backside penetration of the casting liquid was not seen at all, and the length of the separation membrane formed / the length of the support rolled out was 0.992, and the membrane peel strength of the produced separation membrane was 36 cN / 15 mm. The results are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com