Method of directly reducing vanadium-titanium ore hot-pressing blocks in rotary hearth furnace and melting in electric furnace

A technology of vanadium-titanium ore and hot briquetting, applied in the direction of rotary drum furnace, furnace, furnace type, etc., can solve the problem of reducing the production efficiency of the rotary hearth furnace reduction process, increasing the energy consumption and cost of the electric furnace melting process, and not being able to use multi-layer Cloth and other issues, to achieve broad market industrial application prospects, significant social and economic benefits, good separation and enrichment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

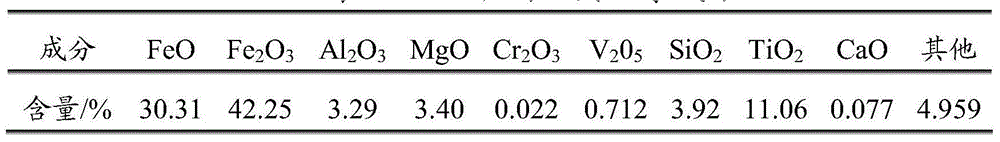

[0031] Taking the vanadium-titanium ore powder that a company is using as raw material, its total iron TFe content is 53.15%, V 2 o 5 The content is 0.712%, TiO 2The content is 11.06%, its chemical composition is shown in Table 1 by mass percentage, and the particle size of the mineral powder is not greater than 0.15mm.

[0032] Table 1 Main chemical components of vanadium-titanite

[0033]

[0034] Taking the bituminous coal powder being used by a company as the carbon-containing raw material, the fixed carbon content is 50.94%, the ash and volatile content are 14.00% and 34.70% respectively, the colloidal layer index of the bituminous coal is 11, and the chemical composition is shown in mass percentage. In Table 2 and Table 3 below, the particle size of bituminous coal powder is not greater than 0.15mm.

[0035] Table 2 Chemical composition of a bituminous coal ( / %)

[0036]

[0037] Table 3 Chemical composition of bituminous coal ash

[0038]

[0039] The abov...

Embodiment 2

[0047] Still take the ore powder and coal powder listed in Example 1 as raw materials.

[0048] The above two raw materials are mixed, mixed, heated and hot-pressed according to the mass percentages of vanadium-titanium ore powder and bituminous coal powder being 74.46% and 25.54% respectively.

[0049] In the hot-pressing process, the hot-pressing temperature is 300°C, and the hot-pressing pressure is 40 MPa. The composition of the vanadium-titanium ore hot-briquette obtained by pressing is shown in Table 5 by mass percentage. The compressive strength of the vanadium-titanium hot-briquette is 1224N, and the drop strength is 6.2 Times / pieces.

[0050] Table 5 Main chemical composition of vanadium-titanium magnetite hot briquettes

[0051]

[0052] The pressed vanadium-titanium ore hot briquettes are put into the hearth of the rotary hearth furnace through the distribution machine, and three layers of distribution are carried out. The reduction temperature of the rotary hea...

Embodiment 3

[0056] Still take the ore powder and coal powder listed in Example 1 as raw materials.

[0057] The above-mentioned two kinds of raw materials are prepared according to the mass percentages of vanadium-titanium ore powder and bituminous coal powder of 71.42% and 28.58%, respectively, and are mixed, heated and hot-pressed.

[0058] In the hot-pressing process, the hot-pressing temperature and hot-pressing pressure are 350°C and 45MPa, respectively. The composition of the vanadium-titanium ore hot-briquettes obtained by final pressing is shown in Table 6. The compressive strength of the vanadium-titanium hot-briquettes is 1482N, and the drop strength is 8 times / indivual.

[0059] Table 6 Main chemical components of vanadium-titanium magnetite hot briquettes

[0060]

[0061] The pressed vanadium-titanium ore hot briquette enters the bottom of the rotary hearth furnace through the distribution machine, and multi-layer distribution is carried out. The thickness of the materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com