Cooperative treatment and application of emulsification waste liquid sludge and waste and old circuit board nonmetallic powder

A waste circuit board and collaborative processing technology, applied in waste treatment, solid waste removal, waste fuel and other directions, can solve the problems of pollution, energy waste, limited consumption, etc., to achieve low energy consumption, low processing cost, high environmental protection benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

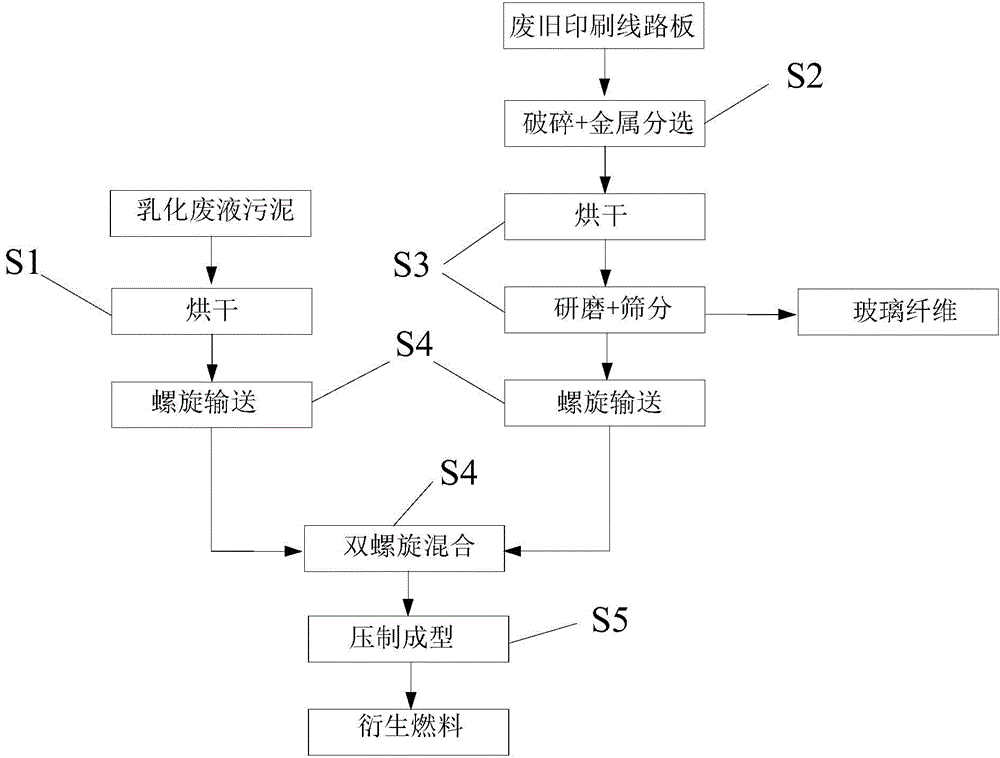

[0022] Such as figure 1 As shown, the first embodiment of the present invention provides a collaborative treatment of emulsified waste liquid sludge and non-metallic powder of waste circuit boards. Taking waste printed circuit boards as an example, it specifically includes the following steps:

[0023] S1: Place the emulsified waste liquid sludge in an environment of 100 ゜C, and dry it for 3 hours under the condition of continuous stirring, until the moisture content drops below 20%, to obtain the first ingredient. It should be noted that the emulsified waste liquid The sludge should not be too dry, and the emulsified waste liquid sludge after drying still has a certain fluidity, which is beneficial to the subsequent material mixing operation;

[0024] S2: performing metal sorting after crushing the dried waste printed circuit boards, removing metals, and obtaining non-metallic broken objects;

[0025] S3: Sieve the non-metallic fragments after metal removal, and remove the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com