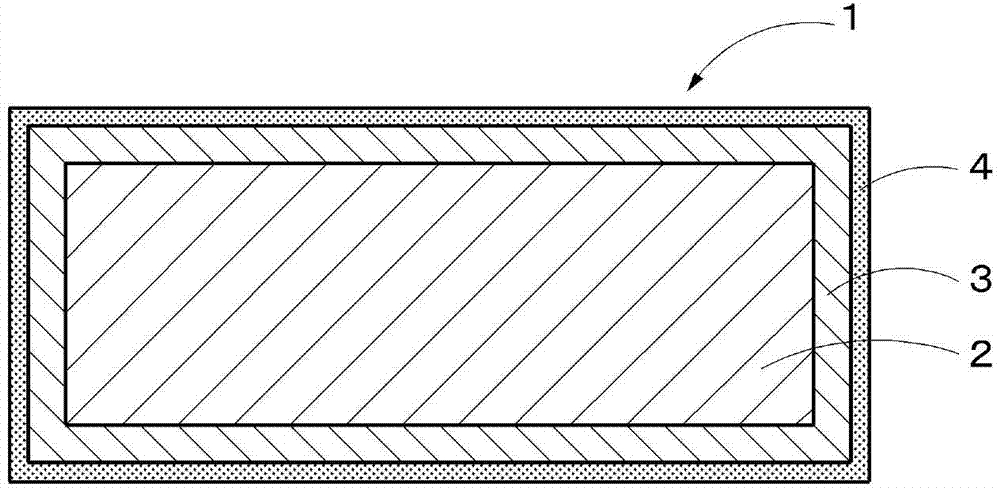

Metal member,terminal,electric wire connection structure and method of manufacturing terminal

A metal component and manufacturing method technology, applied in the direction of conductive connection, contact manufacturing, connection, etc., can solve the problems of reducing the HAZ, improving the absorption rate of the laser wavelength region without discussion, and achieving the effect of reducing the HAZ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

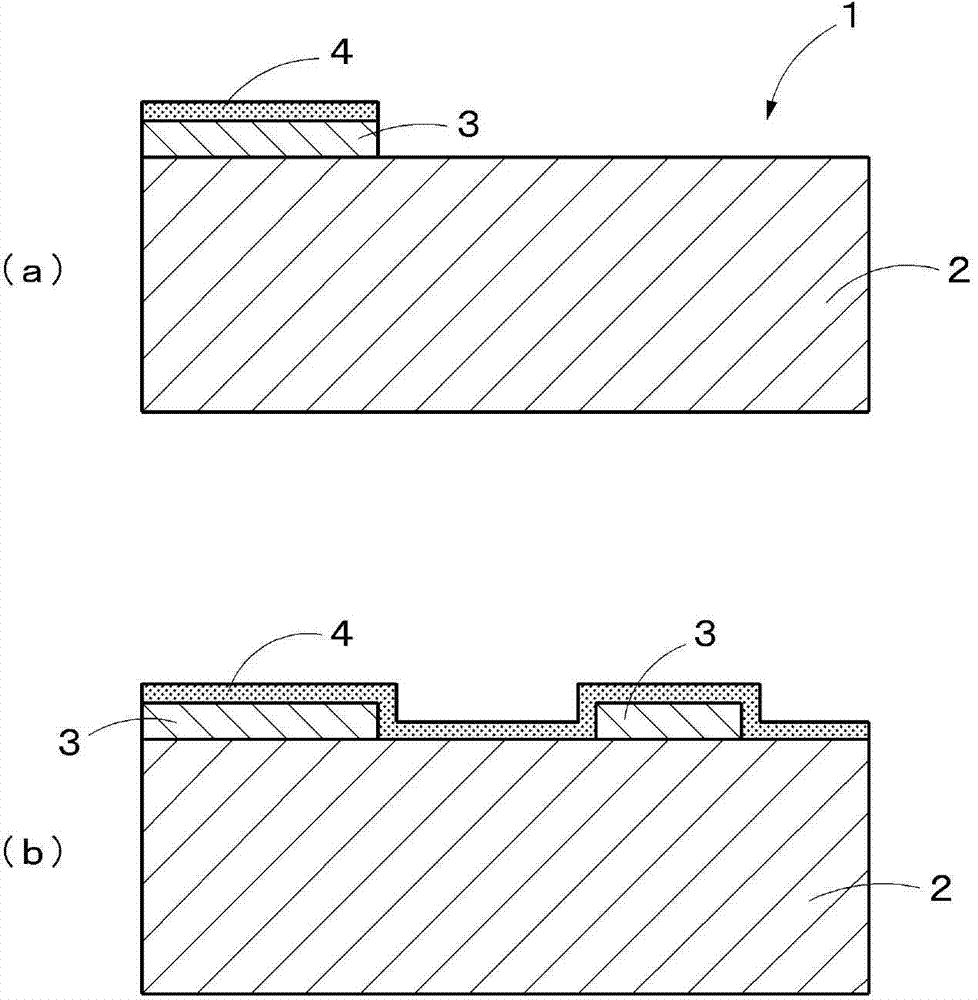

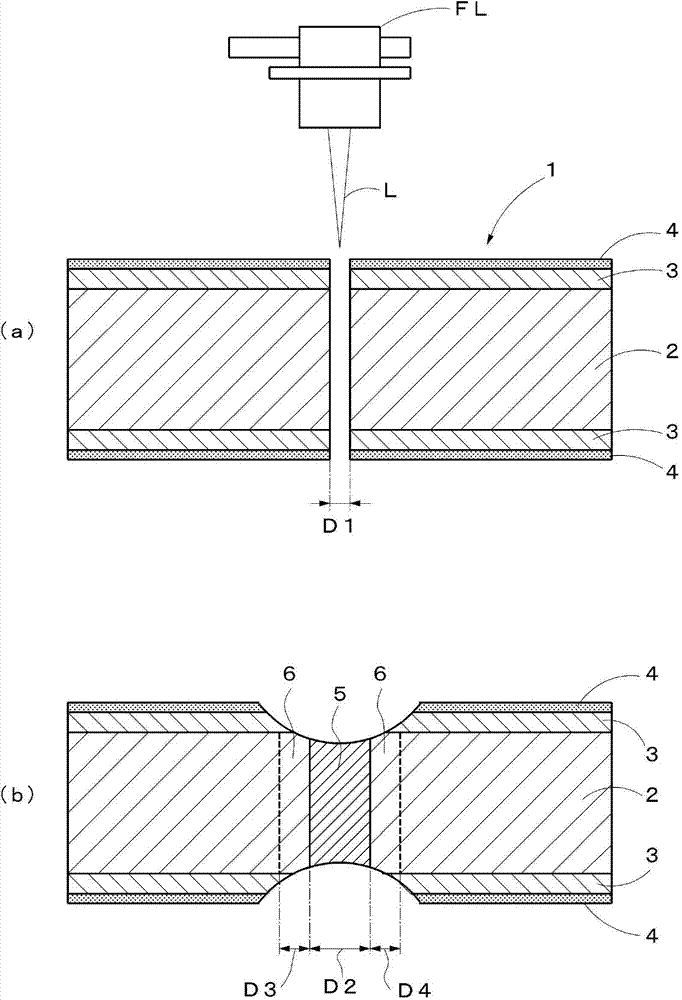

[0100] As the base material of the terminal, copper alloy FAS-680 (trade name) (strip shape, thickness 0.25 mm, H material) manufactured by Furukawa Electric Co., Ltd. was used. FAS-680 is a copper alloy of copper-nickel-silicon type (Ni-Si type).

[0101] Using a commercially available tin plating bath, nickel plating bath, at a specified high current density (tin plating: 5 ~ 10A / dm 2 ;Nickel plating: 20~30A / dm 2 ), and the stirring condition was 500 rpm, and the substrate was subjected to tin plating or nickel plating. By this plating treatment, the thickness of the white metal layer composed of tin plating layer and nickel plating layer is changed as shown in Table 1 in the part where laser welding is performed, that is, the surface of the region that becomes the expanded part of the tube (hereinafter Denoted as "plating layer thickness") and the arithmetic mean roughness Ra of the surface, a tin plating layer or a nickel plating layer (hereinafter referred to as "platin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| double-layer capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com