Copper alloy material for resistance member, manufacturing method therefor, and resistor

A resistance material and manufacturing method technology, applied in the direction of resistors, manufacturing tools, electrical components, etc., to achieve good laser weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

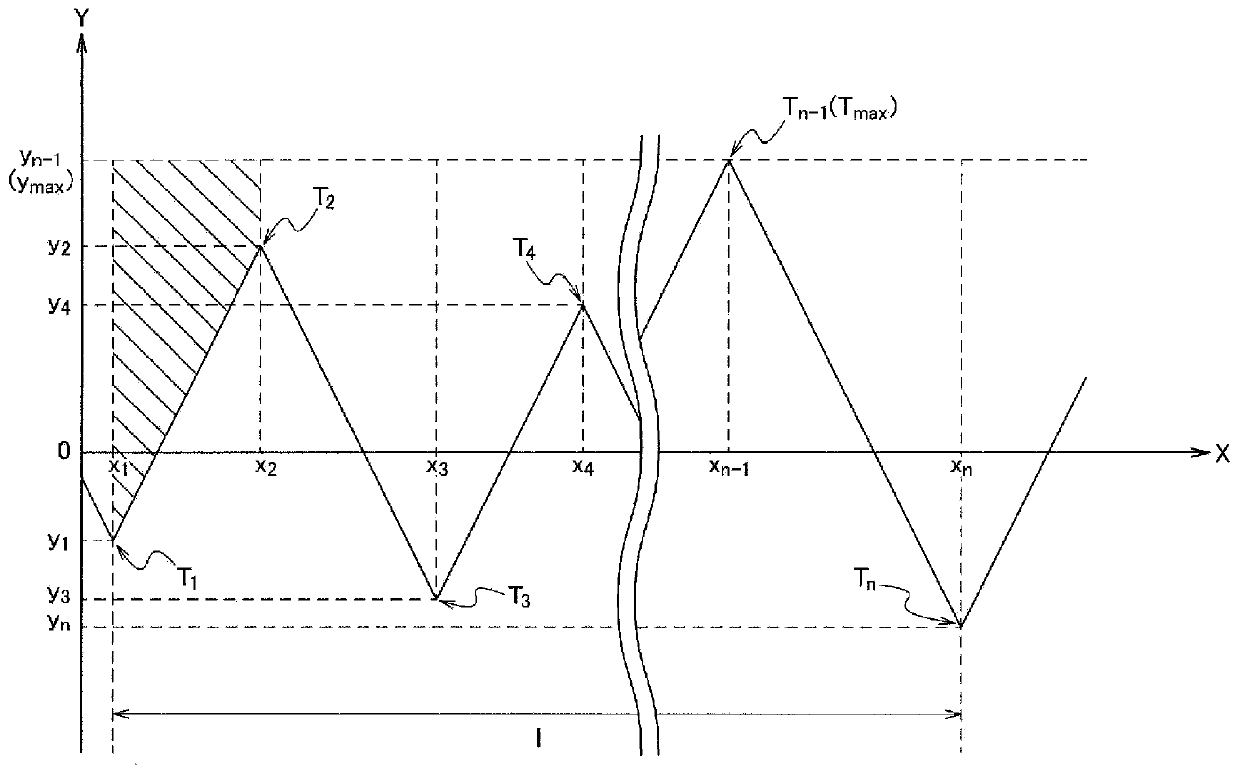

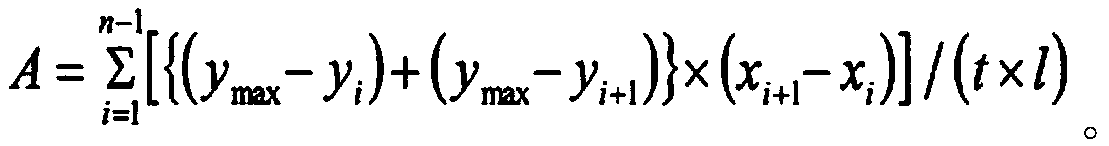

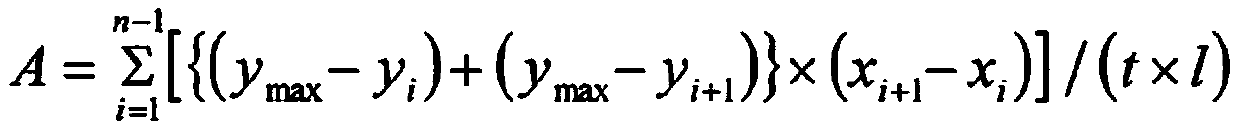

Image

Examples

Embodiment

[0062] Examples and comparative examples are shown below to explain the present invention more specifically.

[0063] An ingot having a predetermined alloy composition is produced by casting (casting process), and after performing a heat treatment of 800°C or higher and 950°C or less, 10 minutes or longer and 10 hours or less to homogenize the alloy components (homogenization heat treatment step), It was formed into a plate shape by hot rolling and water-cooled (hot rolling process). Next, face cutting is performed on the plate material obtained by hot rolling to remove the oxide film on the surface (face cutting process), and then the plate material is cold rolled at a working rate of 50% or more to make the plate thickness thinner to produce a rolled Plate making (cold rolling process).

[0064] Next, the rolled sheet is heat-treated under the conditions of 350°C or higher and 700°C or lower, 10 seconds or longer and 10 hours or shorter, and recrystallization annealing is perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com