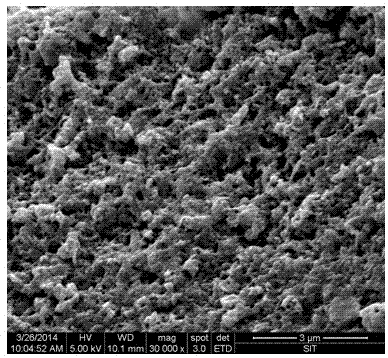

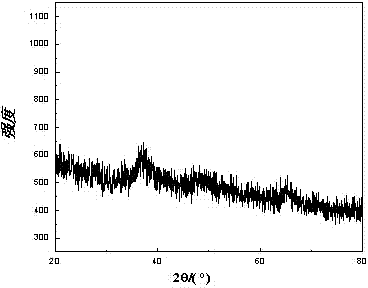

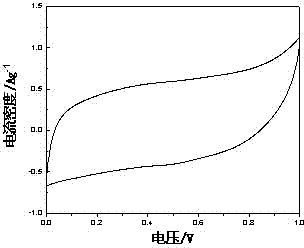

Porous manganese dioxide and preparation method thereof

A manganese dioxide, porous structure technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of poor capacitance, low specific surface area, small pore size, etc., to improve specific capacitance, preparation method Simple and effective to increase the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of porous manganese dioxide, specifically comprising the following steps:

[0024] (1) Slowly add 600 mL of ammonium carbonate solution with a concentration of 1 mol / L to 50 mL of an aqueous aluminum nitrate solution with a temperature of 80 °C and a concentration of 20 mol / L, stir until the solution is transparent, and then control the temperature to -20 °C for freeze-drying , and then transferred to a muffle furnace to control the temperature rise rate of 5°C / min and heat up to 200°C for 10 hours of thermal decomposition, and the obtained solid is aluminum oxide with a porous structure;

[0025] The amount of 20mol / L aluminum nitrate solution and 1mol / L ammonium carbonate used above is calculated on a molar ratio, that is, aluminum nitrate:ammonium carbonate is 1:0.6;

[0026] (2) Immerse 3g of aluminum oxide with a porous structure obtained in step (1) into 20mL of potassium permanganate aqueous solution with a concentration of 0.001mol / L for 0.5...

Embodiment 2

[0034] A preparation method of porous manganese dioxide, specifically comprising the following steps:

[0035] (1) Slowly add 700 mL of ammonium carbonate solution with a concentration of 0.5 mol / L to 50 ml of an aqueous solution of aluminum nitrate with a concentration of 10 mol / L at a temperature of 90 ° C, stir until the solution is transparent, and then control the temperature to -20 ° C for freezing Dry it, then transfer it to a muffle furnace to control the temperature rise rate at 5°C / min and heat up to 300°C for 8 hours to decompose, and the obtained solid is aluminum oxide with a porous structure;

[0036] The amount of 10mol / L aluminum nitrate aqueous solution and 0.5mol / L ammonium carbonate aqueous solution used above is calculated on a molar ratio, that is, aluminum nitrate:ammonium carbonate is 1:0.7;

[0037] (2) Immerse 3 g of aluminum oxide with a porous structure obtained in step (1) into 20 mL of potassium permanganate aqueous solution with a concentration of...

Embodiment 3

[0045] A preparation method of porous manganese dioxide, specifically comprising the following steps:

[0046] (1), with the step (1) of embodiment 1, obtain the aluminum oxide with porous structure;

[0047] (2) Immerse 3g of aluminum oxide with a porous structure obtained in step (1) into 20mL of potassium permanganate aqueous solution with a concentration of 0.005mol / L for 0.5h, allowing potassium permanganate to fully enter the three In the pores of alumina, then suction filtration;

[0048] The filter cake obtained by suction filtration is immersed in 40mL of manganese chloride aqueous solution with a concentration of 0.015mol / L, and the generation reaction of manganese dioxide is carried out under the control stirring speed of 2000-3000r / min for 1-3h, and then suction filtration again;

[0049] Add the filter cake obtained by suction filtration again to 30ml of sulfuric acid aqueous solution with a concentration of 30% by volume, and react at a temperature of 80°C for 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com