Calcium-containing copper-based composite oxygen carrier and preparation method thereof

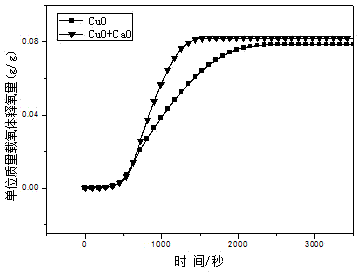

An oxygen carrier, calcium copper technology, applied in the direction of copper oxide/copper hydroxide, calcium/strontium/barium oxide/hydroxide, fuel additives, etc., can solve the problem of reduced activity and cycle stability, easy sintering, The reaction rate is not fast enough to achieve the effect of oxygen release rate and oxygen release quality improvement, good dispersion, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of a calcium-copper-based composite oxygen carrier, comprising the following steps:

[0034] Step 1: Add Ca(NO 3 ) 2 The solution was added dropwise to Cu(NO 3 ) 2 solution, stir until uniformly mixed;

[0035] Step 2: Add citric acid solution, and stir while evaporating at 70-80°C until the mixture forms a wet gel;

[0036] Step 3: The wet gel turns into a dry gel after drying;

[0037] Step 4: Calcining the xerogel at 500°C until the organic matter is fully burned and the nitrate is completely decomposed, then the temperature is raised to 800°C to activate the oxygen carrier;

[0038] Step 5: Grinding and sieving the oxygen carrier particles obtained in step 4 to obtain the calcium-containing copper-based composite oxygen carrier.

[0039] Cu(NO 3 ) 2 and Ca(NO 3 ) 2 The mass ratio of is 21.38:1, and the molar ratio of citric acid described in step 2 and Cu atom is 2:1.

[0040] The drying condition in step 3 is to dry at 105° C. for 2...

Embodiment 1

[0044] Take 28.62 g Cu(NO 3 ) 2 ·3H 2 O was put into a 500 ml beaker, and 100 ml of distilled water was added, and then the beaker was placed on a magnetic stirrer with a constant temperature water bath, and the stirring speed was 400 rpm. Take 2.13g Ca(NO 3 ) 2 4H 2 O into a 100 ml beaker, add 50 ml of distilled water, stir until completely dissolved. Then add the calcium nitrate solution dropwise to the copper nitrate solution, and stir while adding dropwise. Take 49.87 g of citric acid, put it into a beaker with 100 ml of distilled water and stir until it is completely dissolved. After the above solution is stirred evenly, slowly add the citric acid solution, and stir while adding it dropwise. After stirring for 6 hours, the solution had dehydrated into a viscous wet gel. The wet gel was placed in a forced air drying oven at 105 °C, and after drying for 24 hours, the wet gel in the beaker became a dry gel. Take out the dry gel, place it in a muffle furnace at 500°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com