A kind of lightweight partition board and preparation method thereof

A light-weight partition board and paraffin technology, applied in the field of building materials, can solve the problem of low energy consumption of wall boards, achieve the effects of reducing self-weight, improving human comfort, and wide distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

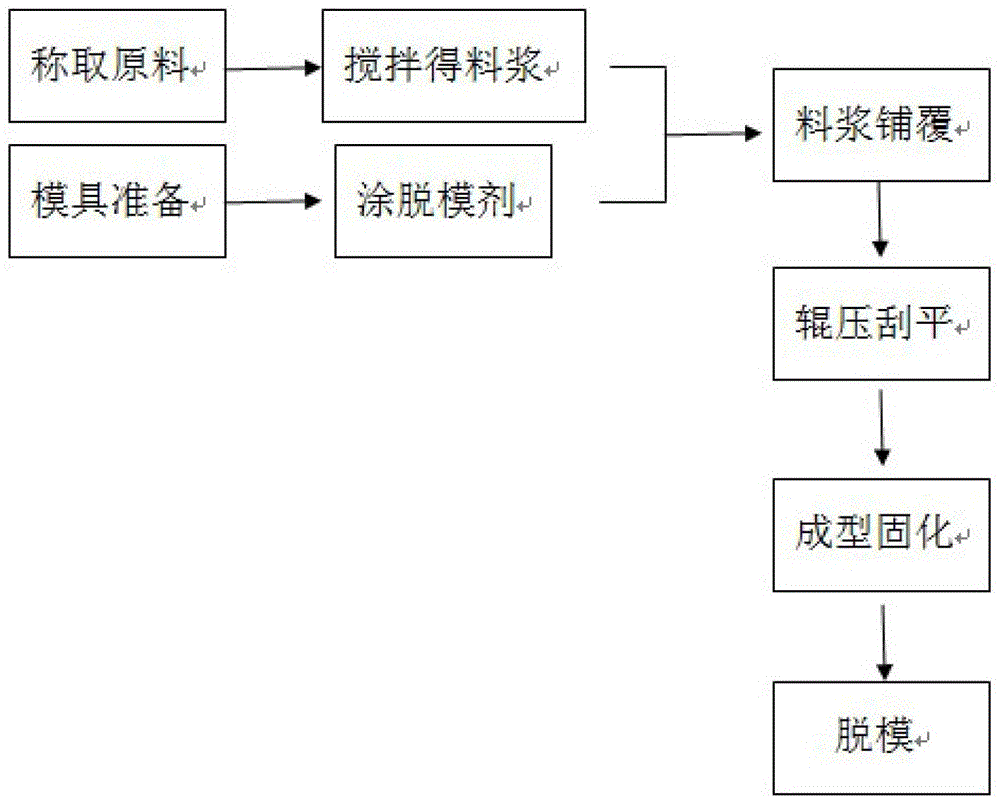

[0031] Such as figure 1 Shown, a kind of method for preparing lightweight partition board, comprises the following steps:

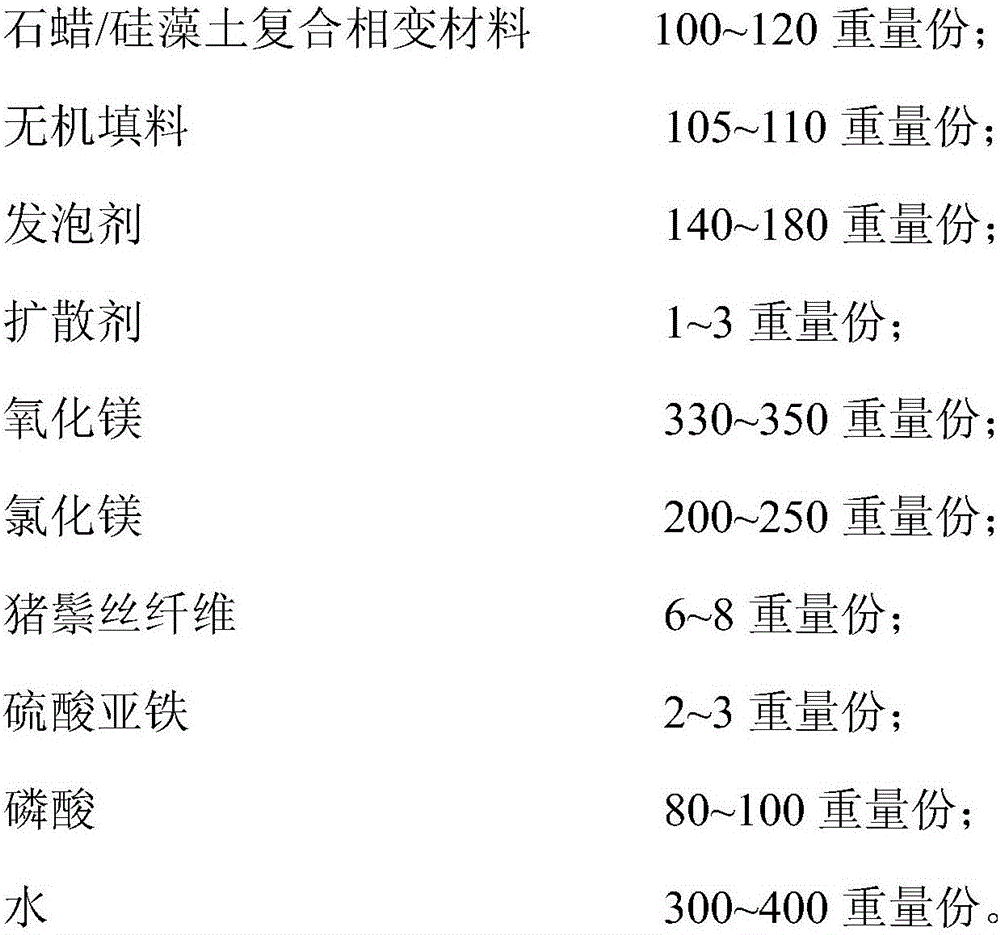

[0032] 1) At room temperature, take 100 parts by weight of paraffin / diatomite composite phase change material, 330 parts by weight of magnesium oxide, 200 parts by weight of magnesium chloride, and 300 parts by weight of water into the stirring device, stir for 15 minutes, and then add 105 parts by weight of stone powder, One or more of construction waste and coal ash powder, 6 parts by weight of pig bristle fiber, 1 part by weight of sodium methylenebisturide sulfonate, 2 parts by weight of ferrous sulfate, 80 parts by weight of phosphoric acid, 140 parts by weight of monofluorine Ethylene dichloride is put into the stirring device, and the slurry is obtained after stirring for 40min;

[0033] 2) Fix the mold on the worktable, and apply a layer of saponified oil or emulsified oil on the inner wall of the mold;

[0034] 3) Pour the slurry prepared in st...

Embodiment 2

[0036] Such as figure 1 Shown, a kind of method for preparing lightweight partition board, comprises the following steps:

[0037] 1) At room temperature, add 110 parts by weight of paraffin / diatomite composite phase change material, 340 parts by weight of magnesium oxide, 230 parts by weight of magnesium chloride, and 350 parts by weight of water into the stirring device, stir for 15 minutes, and then add 108 parts by weight of stone powder, One or more of construction waste and coal ash powder, 7 parts by weight of pig bristle fiber, 2 parts by weight of sodium methylenebisturide sulfonate, 2.5 parts by weight of ferrous sulfate, 90 parts by weight of phosphoric acid, 160 parts by weight of monofluorine Ethylene dichloride is put into the stirring device, and the slurry is obtained after stirring for 40min;

[0038] 2) Fix the mold on the worktable, and apply a layer of saponified oil or emulsified oil on the inner wall of the mold;

[0039] 3) Pour the slurry prepared in ...

Embodiment 3

[0041] Such as figure 1 Shown, a kind of method for preparing lightweight partition board, comprises the following steps:

[0042] 1) At room temperature, take 120 parts by weight of paraffin / diatomite composite phase change material, 350 parts by weight of magnesium oxide, 250 parts by weight of magnesium chloride, and 400 parts by weight of water into the stirring device, stir for 15 minutes, and then add 110 parts by weight of stone powder, One or more of construction waste and coal ash powder, 8 parts by weight of pig bristle fiber, 3 parts by weight of sodium methylenebissulfate, 3 parts by weight of ferrous sulfate, 100 parts by weight of phosphoric acid, 180 parts by weight of monofluorine Ethylene dichloride is put into the stirring device, and the slurry is obtained after stirring for 40min;

[0043] 2) Fix the mold on the worktable, and apply a layer of saponified oil or emulsified oil on the inner wall of the mold;

[0044] 3) Pour the slurry prepared in step 1) e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com