Method for preparing homogenous nano vaterite type calcium carbonate through limestone acidolysis

A limestone and nanosphere technology, applied in the direction of calcium carbonate/strontium/barium, etc., to achieve the effect of low energy consumption, avoiding waste of fossil fuel resources and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

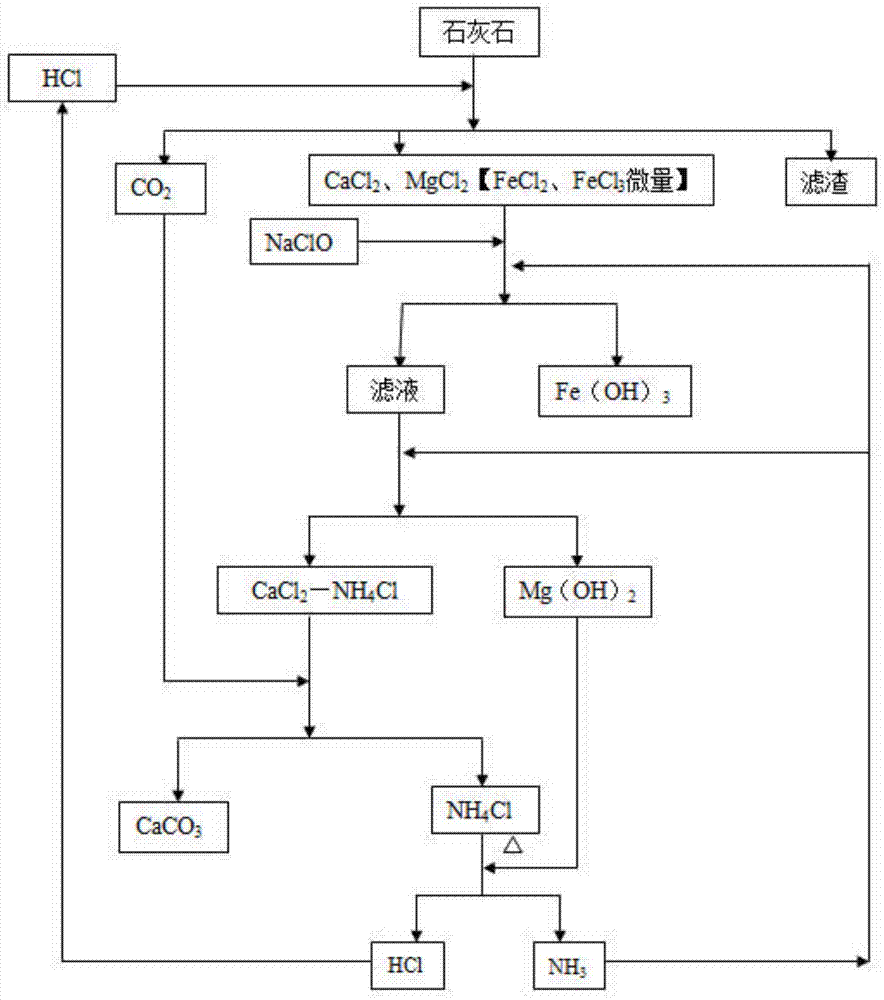

Method used

Image

Examples

Embodiment 1

[0028] 1. Raw material pretreatment: crush and grind limestone ore into limestone powder with particle size less than 150μm;

[0029] 2. Acid hydrolysis of limestone: Weigh 50g of limestone powder and add it to 540mL of 2mol / L hydrochloric acid solution, acidolysis at room temperature with a stirring speed of 200r / min for 30min, and filter to obtain Ca 2+ , Mg 2+ , Fe 3+ , Fe 2+ and Cl - a solution of ions;

[0030] 3, impurity removal: get the solution 200mL that step 2 obtains, add the NaClO solution of 0.08g available chlorine content 6wt%; Add the ammoniacal liquor that concentration is 13.33mol / L after completion of reaction, adjust pH to be 8.5, obtain ferric hydroxide precipitation, static After standing for 45 minutes, remove the ferric hydroxide by suction filtration; continue to add ammonia water with a concentration of 13.33mol / L to adjust the pH to 10.9 to obtain magnesium hydroxide precipitate, and remove the magnesium hydroxide by suction filtration to obtain...

Embodiment 2

[0041] 1. Raw material pretreatment: crush and grind limestone ore into limestone powder with particle size less than 150μm;

[0042] 2. Acid hydrolysis of limestone: Weigh 25g of limestone powder and add it to 270mL of 2mol / L hydrochloric acid solution, acidolyze at room temperature at a stirring speed of 300r / min for 20min, filter after acidolysis to obtain 2+ , Mg 2+ , Fe 3+ , Fe 2+ and Cl - a solution of ions;

[0043] 3, impurity removal: get the solution 200mL that step 2 obtains, add the NaClO solution of 0.082g available chlorine content 4wt%; Add the ammoniacal liquor that concentration is 14.79mol / L after completion of reaction, adjust pH to be 9, obtain ferric hydroxide precipitation, static After standing for 45 minutes, remove the ferric hydroxide by suction filtration; continue to add ammonia water with a concentration of 14.79mol / L to adjust the pH to 11.2 to obtain magnesium hydroxide precipitate, and remove the magnesium hydroxide by suction filtration to ...

Embodiment 3

[0049] 1. Raw material pretreatment: crush and grind limestone ore into limestone powder with particle size less than 150μm;

[0050] 2. Acid hydrolysis of limestone: Weigh 25g of limestone powder and add it to 270mL of 2mol / L hydrochloric acid solution, acidolysis at room temperature with a stirring speed of 200r / min for 30min, and filter to obtain Ca 2+ , Mg 2+ , Fe 3+ , Fe 2+ and Cl - a solution of ions;

[0051] 3, impurity removal: get the solution 200mL that step 2 obtains, add the NaClO solution of 0.075g available chlorine content 10wt%; Add the ammoniacal liquor that concentration is 13.33mol / L after completion of reaction, adjust pH to be 8, obtain ferric hydroxide precipitation, static After standing for 60 minutes, remove the ferric hydroxide by suction filtration; continue to add ammonia water with a concentration of 13.33mol / L to adjust the pH to 10.8 to obtain magnesium hydroxide precipitate, and remove the magnesium hydroxide by suction filtration to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com