Counter-blowing type hot-cutting hood with cooling effect

A technology of cooling effect and hot-cut hood, which is applied in the field of mechanical equipment, can solve the problems of lower production efficiency, easy to stick together, troublesome operation, etc., and achieve the effects of improving production efficiency, easy air-drying, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

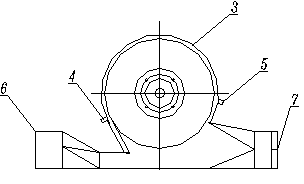

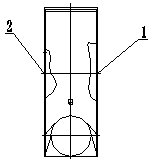

[0012] refer to Figure 1-3 , this specific embodiment adopts the following technical scheme: it includes the first circular seam 1, the second circular seam 2, the cover body 3, the water inlet pipe joint 4, the water outlet pipe joint 5, the high-pressure fan blowing into the connecting pipe 6 and the outlet Material pipeline 7, one side of the cover body 3 is provided with a first circular seam 1, the other side of the cover body 3 is provided with a second circular seam 2, and both sides of the outer circumference of the cover body 3 are respectively provided with water inlet pipes Connector 4 and outlet pipe joint 5, one end below the cover body 3 is provided with high-pressure fan blowing into connecting pipe 6, and the other end is provided with discharge pipe 7, and high-pressure blowing blowing connecting pipe 6 is communicated with discharge pipe 7.

[0013] The cover body 3 is a circular cylinder with a water interlayer in the inner cavity.

[0014] The first circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com