A heating and oscillating magnetic separation device

A magnetic separation device, heating oscillation technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of high probability of cross-contamination, bulky, poor controllability, etc., to achieve simple mechanical structure, avoid interference, Guaranteed effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment mode, the patent of the present invention is described in further detail:

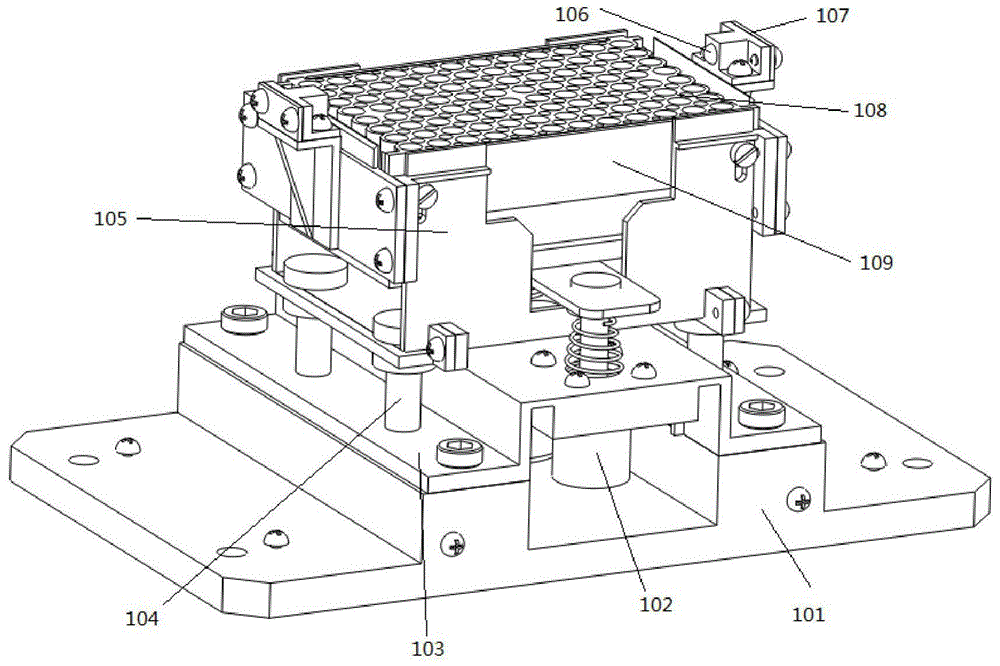

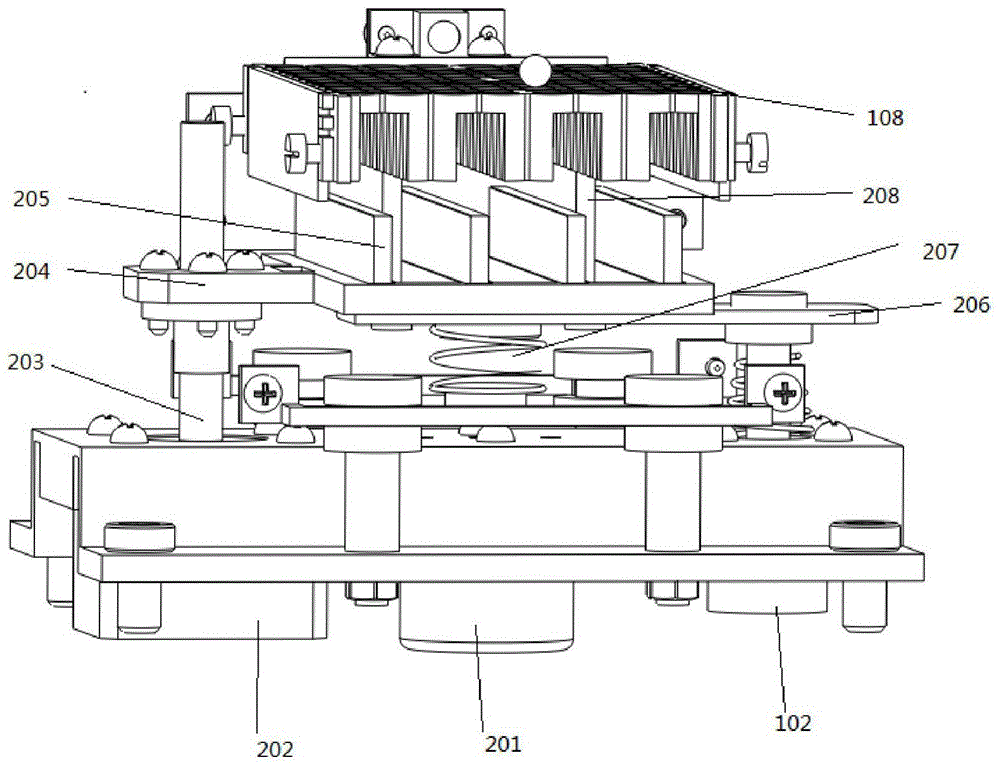

[0028] A heating and oscillating magnetic separation device includes three main modules, namely a magnetic separation module, a heating module and a vibration module. The magnetic separation module includes linear motors, lead screws, magnet brackets, and permanent magnets. The heating module includes electromagnetic pushers, springs, support plates, support columns, heating tanks, and heating films. The vibration module includes vibration motors and eccentric hammers. In addition, it also includes auxiliary structures such as bases, fixed plates, elastic columns and main frames.

[0029] The base is in the shape of a groove, and the middle part is fixed with a linear motor, an electromagnetic push-pull and a vibrating motor, and two fixing plates are placed on both sides of the middle.

[0030] The four corners of the fixing plate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com