Horizontal type numerically-controlled machine tool for cutting

A CNC machine tool and cutting processing technology, applied in metal processing machinery parts, metal processing equipment, turning equipment and other directions, can solve the problems of slow response speed of the chuck, low movement accuracy, easy breaking and locking of the cylinder, etc., to improve the response The effect of speed, moving speed and high precision of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

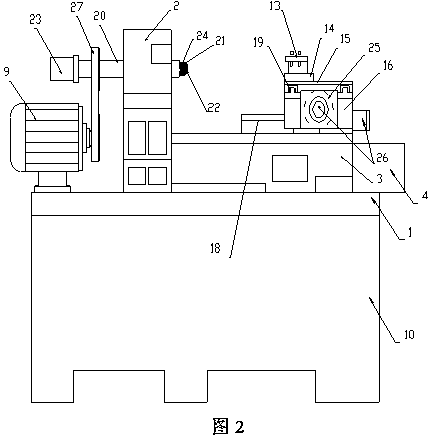

[0014] Depend on figure 1 Known, a cutting processing horizontal CNC machine tool, including bed 1, bedside box 2, bed saddle 3, centralized lubricator 4, protective cover 5, protective sliding door 6, console 7, cooling water tank 8, main motor 9 , the lower part of the bed 1 is connected to the machine base 10, a cooling water tank 8 is placed in the machine base 10, a protective cover 5 is installed on the upper part of the bed 1, and a protective sliding door 6 is arranged on the protective cover 5, and the bed 1 in the protective cover 5 A main motor 9 is installed on the upper left side, a bedside box 2 is installed in the middle, a bed saddle 3 is installed on the right side, a centralized lubricator 4 is installed at the end of the right side, a main shaft 20 is installed in the bedside box 2, and a chuck 21 at the top of the main shaft 20 is installed A collet 22 is installed, and the collet 22 can be replaced with a manual chuck according to the needs of customers. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com