Pump-type discharge container

A container and pump type technology, applied in the direction of spraying device, liquid spraying device, packaging, etc., can solve the problems of accidental liquid leakage, liquid leakage, slight movement of the nozzle head up and down, etc., to achieve the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

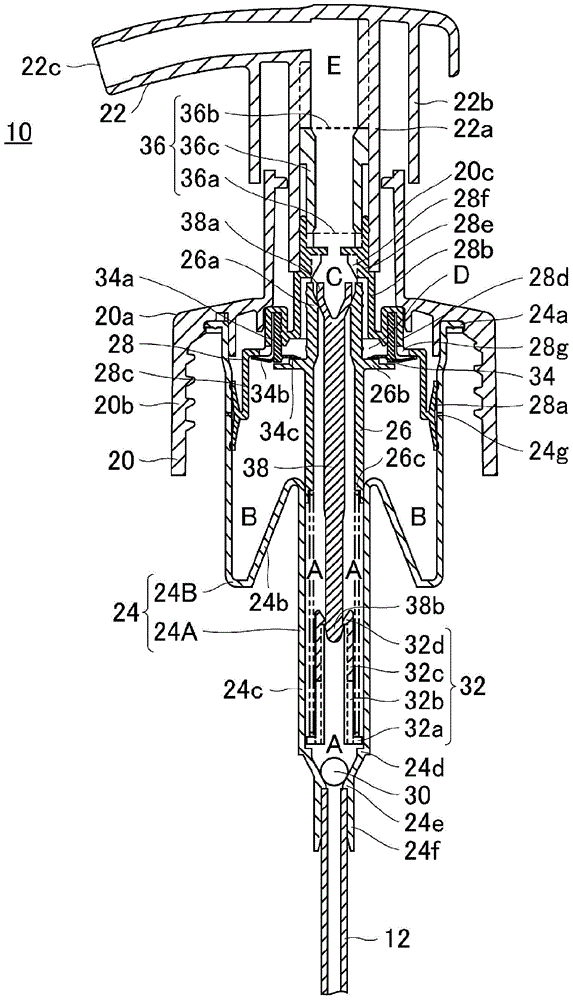

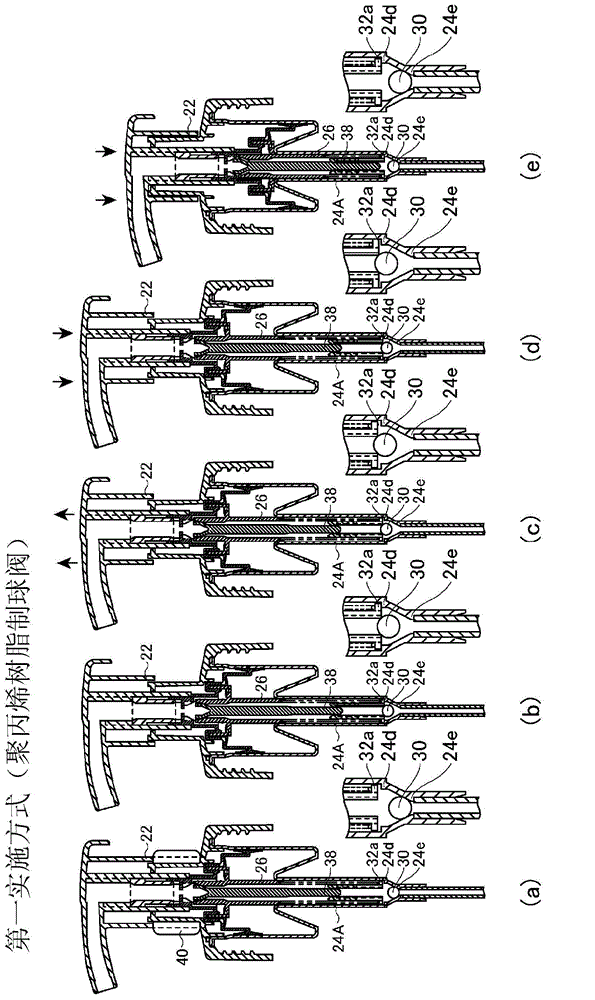

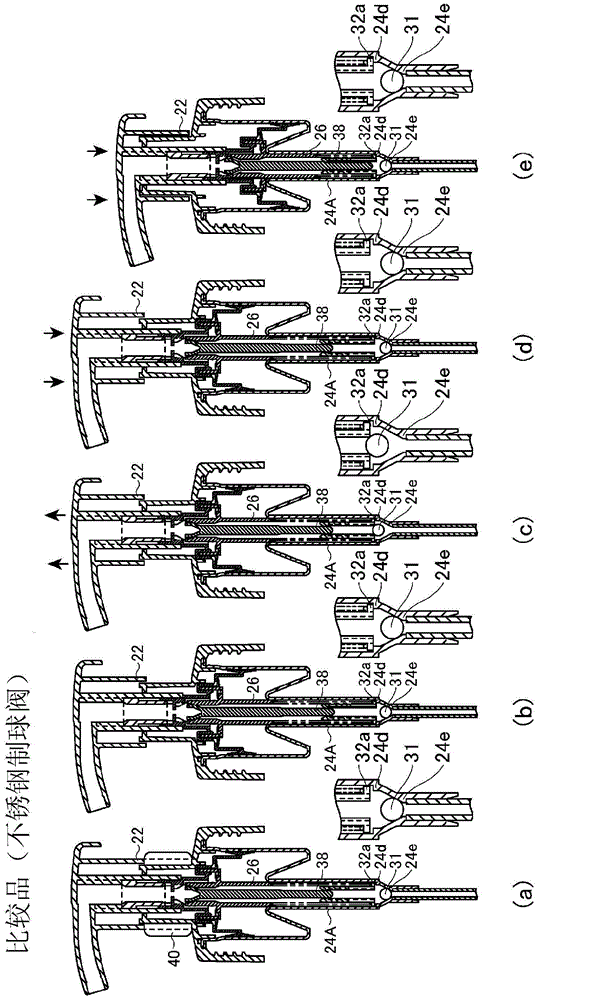

[0033] Hereinafter, preferred embodiments of the present invention will be described based on the drawings. Among them, the pump-type dispensing container of the embodiment shown below is a foam dispensing container, which mixes the foamable liquid contained in the container with air and sprays it in the form of foam, but the present invention is not limited to Such a foam discharge container may be any liquid discharge container for discharging the liquid in the container main body.

[0034]

[0035] The pump-type spray container of this embodiment includes: a container body, which is used to accommodate liquid; a spray pump body, which is mounted on the mouth of the upper end of the container body in a detachable manner; a pipe body, which is connected to the spray pump body; The pump body communicates with and extends to the inside of the container main body.

[0036] figure 1 A sectional view showing the discharge pump body 10 according to the first embodiment of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com