A kind of non-solder package embedded in bga chip for hybrid package

A hybrid packaging, no soldering technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as solder joints, affecting product quality, and air in packaging, to achieve short circuit between, good compatibility, and reduce Effect of Small Thickness and Volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

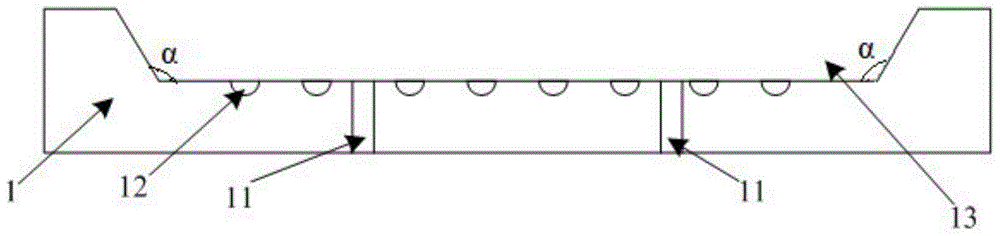

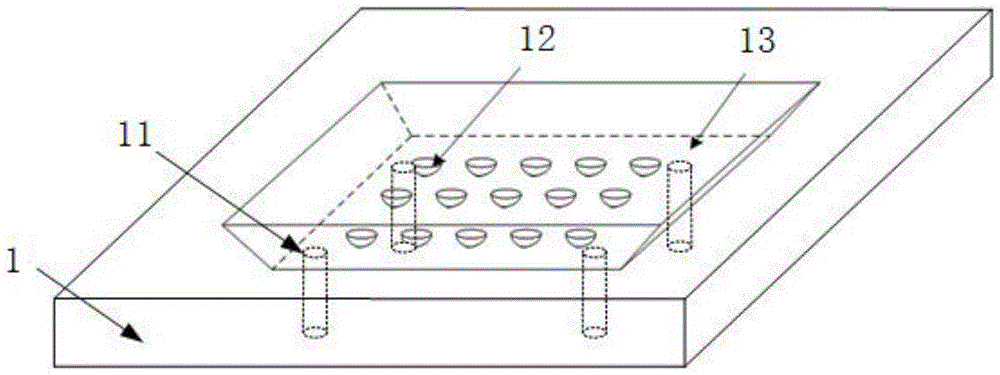

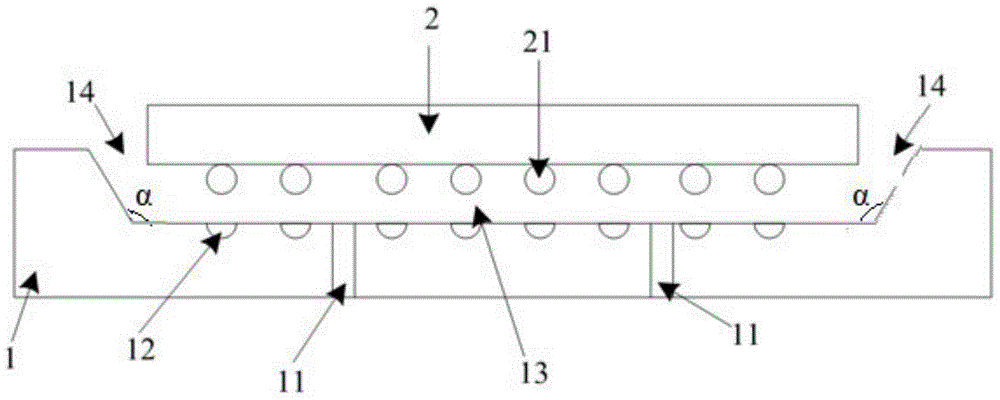

[0028] The present embodiment adopts the BGA chip 2 of 7 * 7mm, and the diameter of the BGA solder ball 21 on the BGA chip is 0.25mm, and the size of the organic substrate mounting cavity 13 that matches this is 7 * 7mm, and the four dimensions of the mounting cavity 13 Both sides are isosceles trapezoidal slopes, the angle α between the isosceles trapezoidal slopes and the bottom surface of the installation cavity is 105°, the depth of the installation cavity 13 is 1 / 6 of the thickness of the organic substrate 1, and the bottom surface of the organic substrate is provided with 2 through holes 11, and the through holes are evenly and symmetrically distributed, the diameter of the hemispherical groove 12 on the bottom surface of the installation cavity is 0.25mm, and the inner surface of the hemispherical groove 12 is plated with a metal tin layer.

Embodiment 2

[0030] The present embodiment adopts the BGA chip 2 of 15 * 15mm, the diameter of the BGA solder ball 21 on the BGA chip is 0.5mm, and the size of the organic substrate mounting cavity 13 that matches this is 15 * 15mm, and the mounting cavity 13 is symmetrical Both sides are isosceles trapezoidal slopes, the angle α between the isosceles trapezoidal slopes and the bottom surface of the installation cavity is 115°, the depth of the installation cavity 13 is 1 / 3 of the thickness of the organic substrate 1, and the bottom surface of the organic substrate is provided with 6 through holes. Holes 11, and the through holes are evenly and symmetrically distributed, the diameter of the hemispherical groove 12 on the bottom surface of the installation cavity is 0.5mm, and the inner surface of the hemispherical groove 12 is plated with a metal tin layer.

Embodiment 3

[0032]The present embodiment adopts the BGA chip 2 of 20 * 20mm, the diameter of the BGA solder ball 21 on the BGA chip is 1mm, and the size of the organic substrate mounting cavity 13 that matches this is 20 * 20mm, and the four sides of the mounting cavity 13 They are all isosceles trapezoidal slopes, the angle α between the isosceles trapezoidal slopes and the bottom surface of the installation cavity is 130°, the depth of the installation cavity is 1 / 2 of the thickness of the organic substrate, and the bottom surface of the organic substrate is provided with 12 through holes 11, and through The holes are evenly and symmetrically distributed, and the diameter of the hemispherical groove 12 on the bottom surface of the installation cavity is 1mm, and the inner surface of the hemispherical groove 12 is plated with a metal tin layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com