Fin evaporator and electric refrigerator adopting fin evaporator

A technology of finned evaporators and evaporators, applied in evaporators/condensers, refrigeration components, refrigerators, etc. Poor thermal efficiency and other problems, to avoid the reduction of cooling capacity, insufficient heat transfer, and avoid uneven frosting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

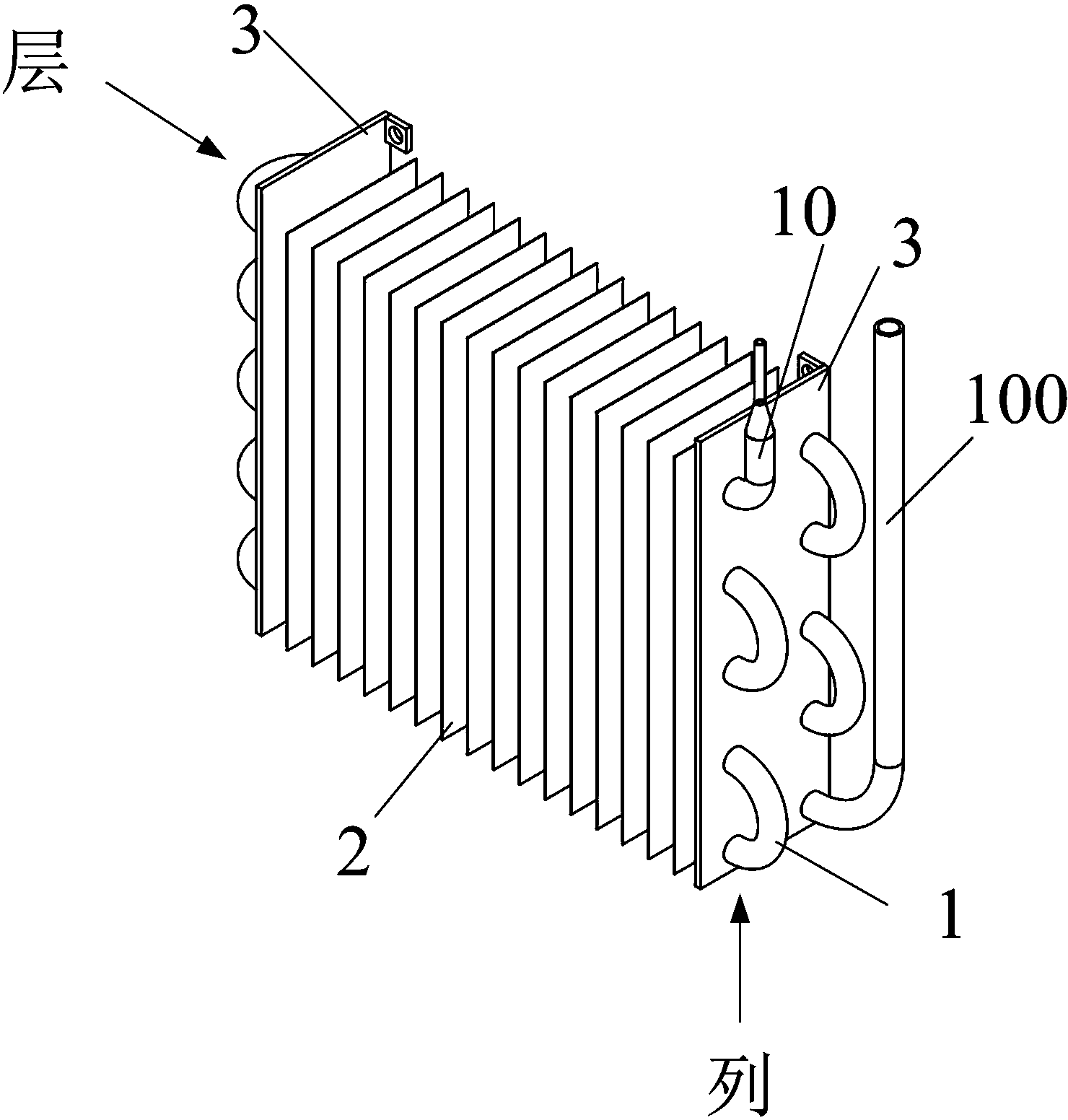

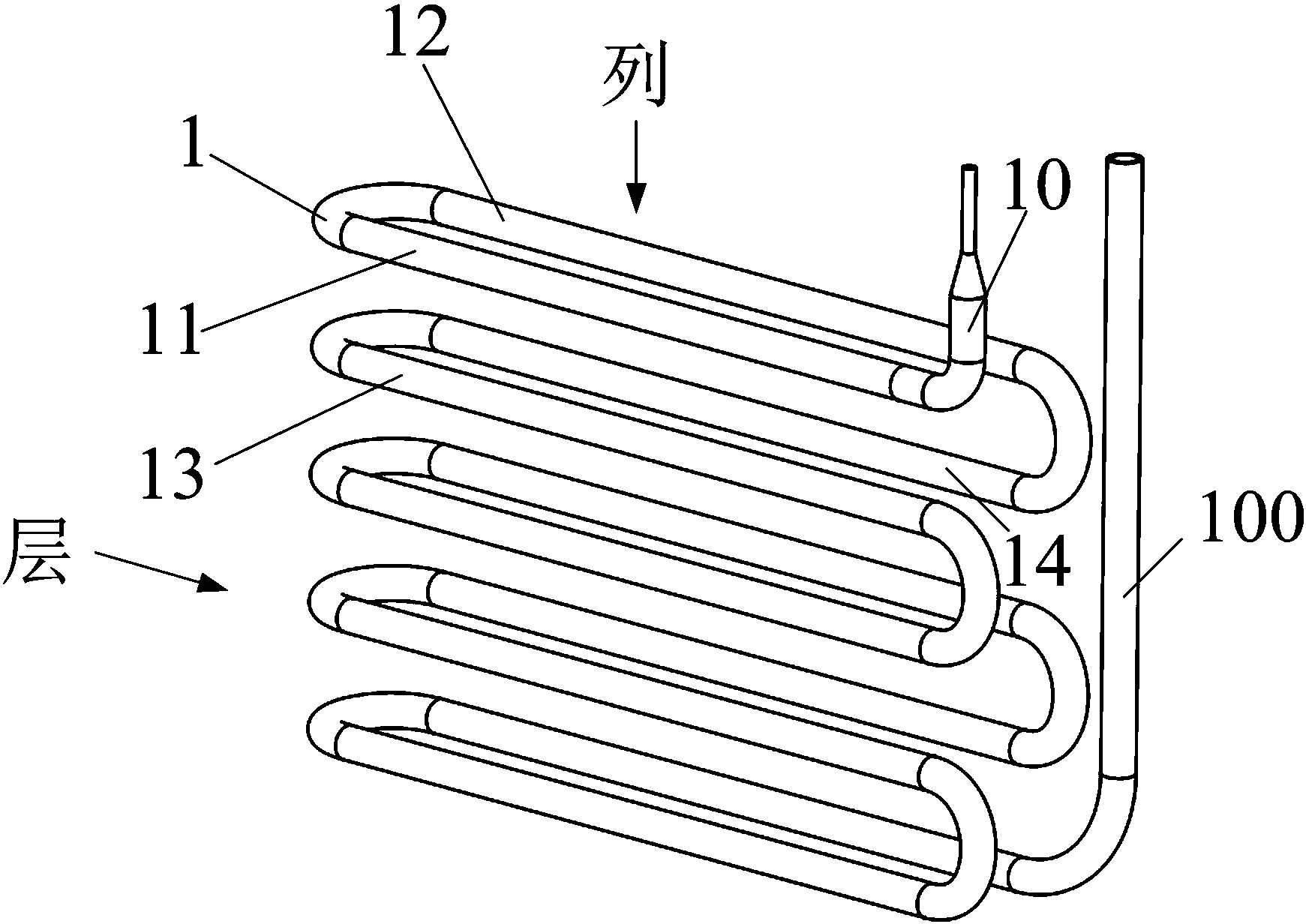

[0036] like figure 1 , 2 , Shown in 3 and 4 is to invent a kind of installation structure of evaporator. Including evaporation tube 1, fins 2, fixed plate 3. The fixing plate 3 plays a role of fixing the evaporation tube 1 at the left and right ends, and the fixing effect of the evaporator. The evaporating tube 1 passes through the fins 2 and the fixed plate 3, increasing the heat exchange area.

[0037] The temperature at the inlet end 10 of the evaporator tube is relatively low, and the temperature at the outlet end 100 of the evaporator tube is relatively high. During the installation, direct heat conduction between the evaporator outlet section and the evaporator outlet section through the fins is firstly avoided. In the first layer, enter the first row of evaporation tubes 11 from the evaporator inlet port 10, the first layer of the first row of evaporation tubes 11 is connected to the first layer of the second row of evaporation tubes 12 through the elbow, the evapora...

Embodiment 2

[0042] like Figure 5 , 6 , Shown in 7 and 8 is to invent a kind of installation structure of evaporator. The difference between this example and Example 1 is that the distance between layers is slightly smaller, and the layers are staggered. 13 The connecting line is perpendicular to the layer. In Example 2, the line connecting the first row of evaporating tubes 11 on the first layer and the first row of evaporating tubes 13 on the second layer faces the layer at an angle of 60 degrees.

[0043] The advantage of this example is that while maintaining the diameter of the connecting elbow of the evaporating tube 1, the distance between layers is reduced, so that the number of layers arranged in the same height is increased.

Embodiment 3

[0045] like Figure 9 , 10 , Shown in 11 and 12 is to invent a kind of installation structure of evaporator. The difference between this example and the second example is that there are three rows of evaporation tubes 1 , that is, each layer is increased from two evaporation tubes 1 to three evaporation tubes 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com