A kind of yttrium-lithium fluoride composite crystal and preparation method thereof

A technology of yttrium-lithium fluoride and composite crystal, applied in the field of yttrium-lithium fluoride composite crystal and its preparation, can solve the problems of inability to guarantee strict matching of crystal orientations, unfavorable laser output efficiency, loss of yttrium-lithium fluoride composite crystal, etc. It is convenient for large-scale industrial application, reducing the birefringence effect and overcoming the effect of thermal expansion and detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

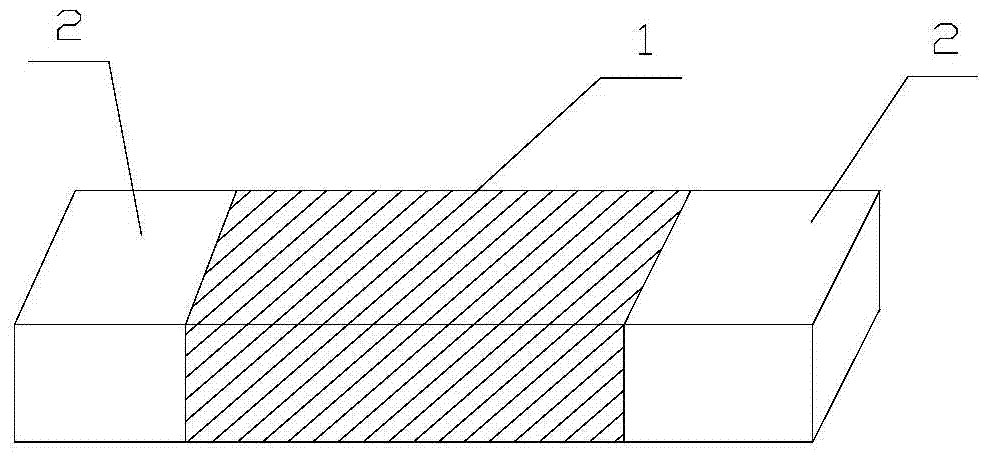

Image

Examples

preparation example Construction

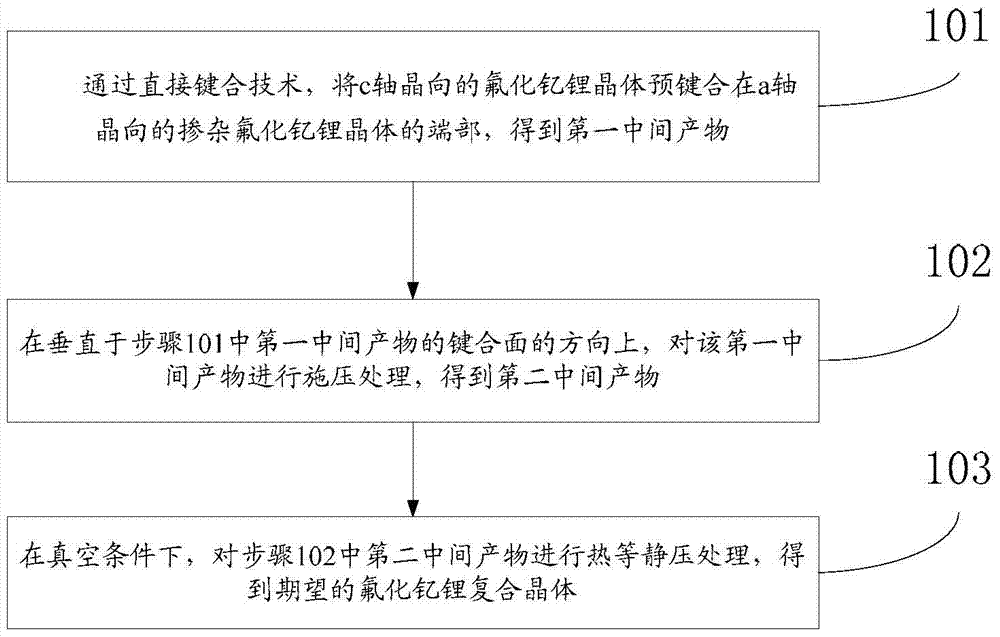

[0052] In the second aspect, the embodiment of the present invention provides a preparation method of yttrium lithium fluoride composite crystal, with figure 2 is a flowchart of the method. as attached figure 2 As shown, the method includes:

[0053] Step 101 , pre-bond the c-axis yttrium lithium fluoride crystal to the end of the a-axis doped yttrium lithium fluoride crystal by direct bonding technology to obtain a first intermediate product.

[0054] Step 102: Apply pressure to the first intermediate product in a direction perpendicular to the bonding surface of the first intermediate product in step 101 to obtain a second intermediate product.

[0055] Step 103, performing hot isostatic pressing on the second intermediate product in step 102 to obtain the desired yttrium-lithium fluoride composite crystal.

[0056] The method provided by the embodiment of the present invention overcomes the problem of thermal expansion separation that easily exists when crystals in dif...

Embodiment 1

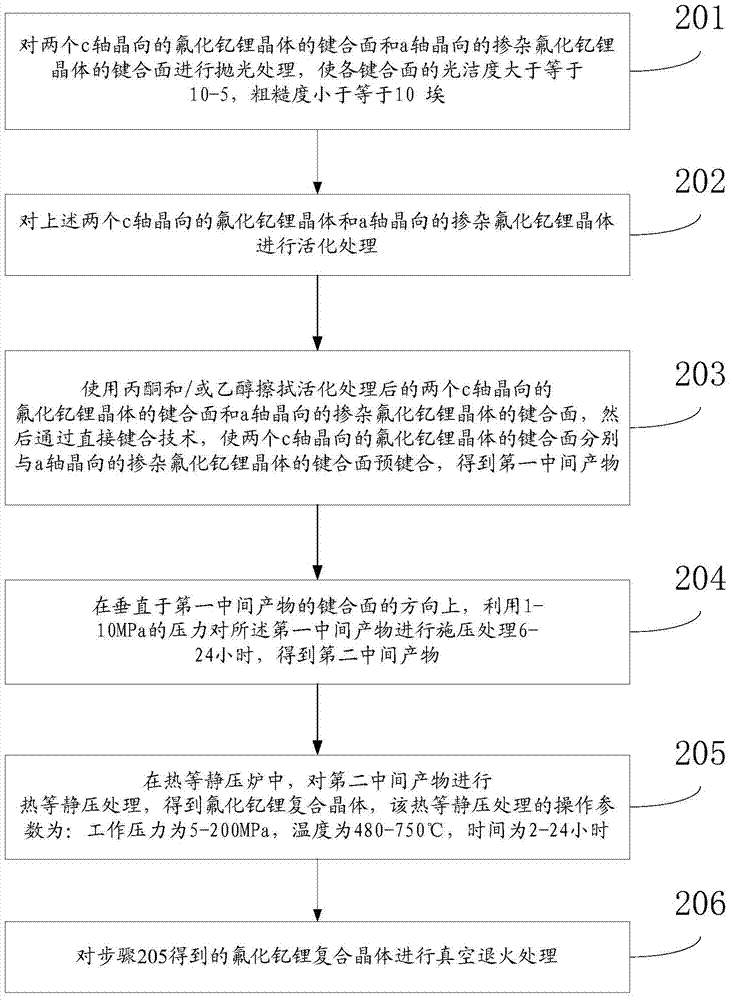

[0084] Step 1. Take two c-axis yttrium lithium fluoride crystals and one a-axis doped yttrium lithium fluoride crystal, respectively polish the bonding surfaces of these three crystals, so that each bonding surface The smoothness is greater than 10-5, and the roughness is less than 10 angstroms. Wherein, the a-axis doped yttrium lithium fluoride crystal is doped with 2.0 at% thulium ions.

[0085] Step 2. Soak the above-mentioned three crystals after polishing in the active washing solution for 30 minutes. Among them, the active lotion is petroleum ether.

[0086] Step 3. Use acetone to wipe the bonding surfaces of the above-mentioned three crystals after the activation treatment, and then use direct bonding technology to make the bonding surfaces of the two c-axis crystals of yttrium lithium fluoride crystals respectively and the a-axis crystals. The bonding surfaces opposite to the doped yttrium lithium fluoride crystals are pre-bonded to obtain a first intermediate produc...

Embodiment 2

[0092] Step 1. Take two c-axis yttrium lithium fluoride crystals and one a-axis doped yttrium lithium fluoride crystal, respectively polish the bonding surfaces of these three crystals, so that each bonding surface The smoothness reaches 10-5 and the roughness reaches 9 angstroms. Wherein, the a-axis doped yttrium lithium fluoride crystal is doped with 5.0 at% holmium ions.

[0093] Step 2. Soak the above three crystals after polishing in the active washing solution for 40 minutes. Wherein, the active washing solution includes toluene and chloroform.

[0094] Step 3, use acetone and / or ethanol to wipe the bonding surfaces of the above-mentioned three crystals after the activation treatment, and then use direct bonding technology to make the bonding surfaces of the two c-axis yttrium lithium fluoride crystals respectively bonded to a The bonding surface opposite to the doped yttrium lithium fluoride crystal in the axial crystal direction is pre-bonded to obtain the first inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com