Toluene and methanol shape-selective alkylation catalyst and method thereof

An alkylation and catalyst technology, applied in the field of toluene and methanol shape-selective alkylation catalysts, can solve problems such as poor catalyst reaction stability, and achieve the effects of improving reaction stability, high activity and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

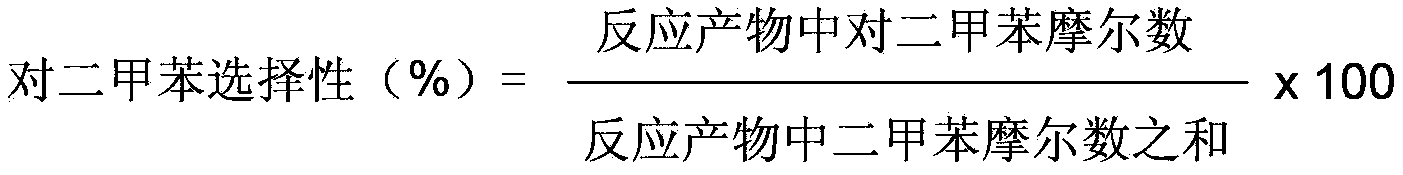

Embodiment 1

[0040] Using SiO 2 / Al 2 o 3 The molar ratio is 80g of 20MCM-22 molecular sieve and 20g of γ-Al 2 o 3 Mix, then add 6.0g of Tianqing powder and mix evenly, then add 3wt% dilute nitric acid as a binder, knead well and evenly, carry out extrusion molding, after drying at 120°C, roast at 540°C to obtain a shaped molecular sieve, which is recorded as MCM-22; The formed 50g MCM-22 molecular sieve is pre-vacuumized, impregnated with an equal volume of ammonium dihydrogen phosphate aqueous solution for 24 hours, dried at 120°C for 24 hours, and then roasted at 550°C for 4 hours, using a temperature program with a heating rate of 2°C / min, to obtain a catalyst loaded with phosphorus oxide; then impregnate it in a vacuum equal volume in an aqueous solution of lanthanum nitrate solution, dry at 120° C., and then roast at 540° C. for 4 hours. The solution was impregnated in equal volume for 24 hours, dried at 120°C, and then calcined at 540°C. The catalyst finally obtained contained ...

Embodiment 2

[0042] Using SiO 2 / Al 2 o 3 The molar ratio is 20MCM-22 molecular sieve 40g, silica sol (SiO 2 , 30%) 59g, γ-Al 2 o 3 Mix 19g and 5g of methyl cellulose evenly, extrude, dry at 120°C, and roast at 550°C to obtain a shaped molecular sieve, which is denoted as MCM-22; pre-vacuumize 50g of the formed MCM-22 molecular sieve, and use molybdic acid Immerse in an equal volume of ammonium aqueous solution for 24 hours, dry at 120°C for 24 hours, then roast at 550°C for 4 hours, use a temperature program at a rate of 2°C / min to obtain a solid that is impregnated with an equal volume of magnesium nitrate aqueous solution for 24 hours. Dry at 120°C for 24 hours, then calcinate at 550°C for 4 hours, use a temperature program at a rate of 2°C / min to obtain a catalyst loaded with molybdenum oxide and magnesium oxide; The petroleum ether solution of silicone oil is impregnated, and after impregnation, it is left to stand until the solvent is completely volatilized. After drying, it is ...

Embodiment 3

[0044] Using SiO 2 / Al 2 o 3 The molar ratio is 80g of 20MCM-22 molecular sieve and 20g of γ-Al 2 o 3 Mix, then add 5g of Tianqing powder and mix evenly, then add 3wt% dilute nitric acid as a binder and knead evenly, carry out extrusion molding, after drying at 120°C, roast at 540°C to obtain a molded molecular sieve, which is recorded as MCM-22; for 10g The formed MCM-22 molecular sieve is pre-vacuumized, vacuum-impregnated with the prepared aqueous solution of cobalt nitrate and ammonium molybdate, filtered off the excess solution, dried at 80°C for 24 hours, and then roasted at 540°C for 4 hours. Using a temperature program with a heating rate of 3°C / min, a catalyst loaded with cobalt oxide and molybdenum oxide was obtained; then pre-vacuumized, vacuum impregnated with an aqueous solution of magnesium nitrate and cerium nitrate, filtered off the excess solution, and dried at 80°C for 24 hours, then roasted at 540°C for 4 hours, using a temperature program, with a heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com