A kind of anti-side leakage degradable polylactic acid sanitary napkin and preparation method thereof

A polylactic acid and sanitary napkin technology, applied in the field of hygiene, can solve the problems of narrow use group, complex production process, single function, etc., and achieve the effects of consistent bacterial growth, good moisture conductivity, and good tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

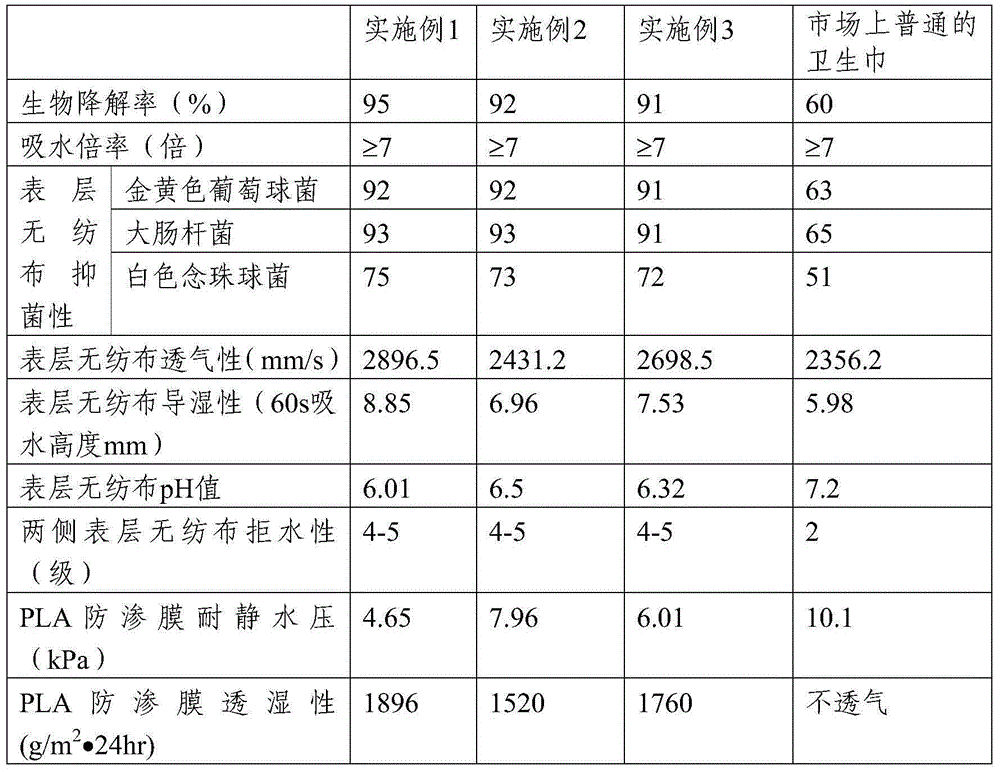

Embodiment 1

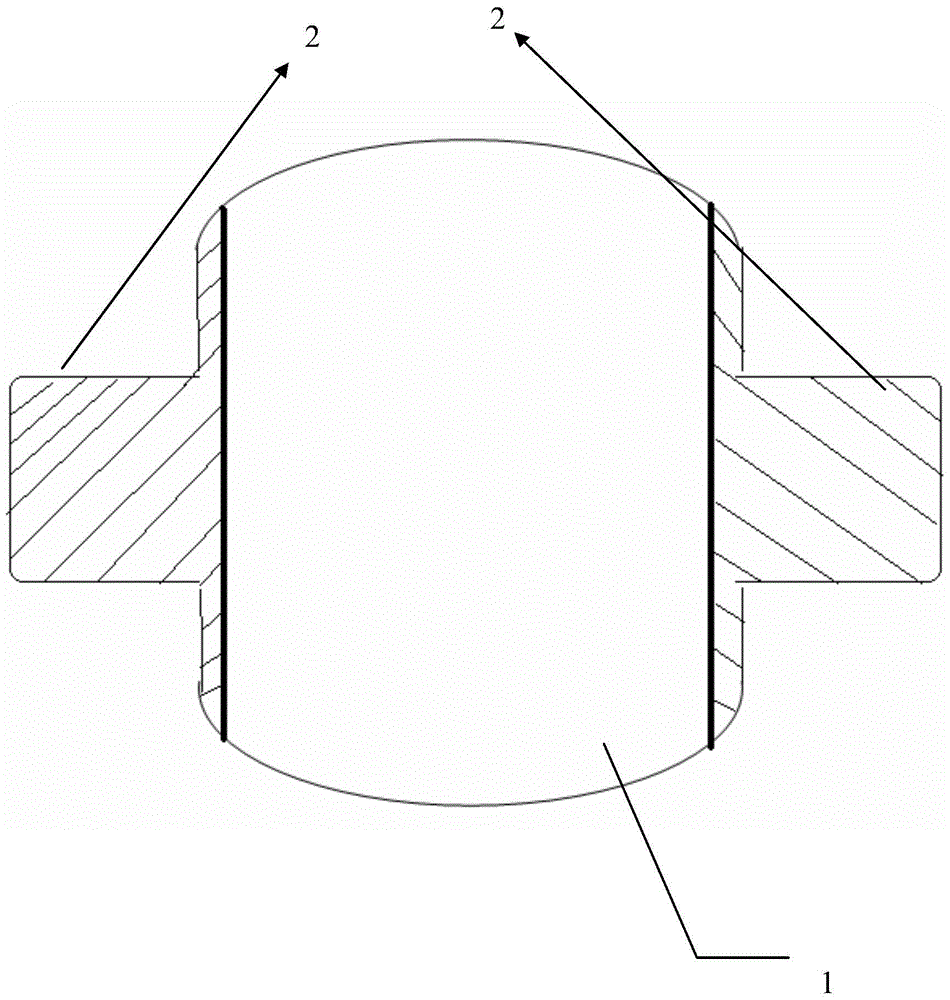

[0043] Such as figure 1 , a kind of anti-side leakage sanitary napkin proposed by the present invention comprises a surface layer non-woven fabric and a bottom anti-seepage film arranged from the inside to the outside, the surface layer non-woven fabric is a three-piece structure, and the surface layer non-woven fabric 1 of the middle sheet is connected with the The surface layer non-woven fabrics 2 of the two wings are bonded together, and the surface layer non-woven fabrics are polylactic acid fiber non-woven fabrics; the middle sheet surface layer non-woven fabrics and the bottom impermeable membrane are filled with wood pulp fibers wrapped by toilet paper to absorb core body.

[0044]Wherein, the thickness of the surface non-woven fabric 1 of the middle sheet is 0.08mm. The thickness of the surface layer non-woven fabric 2 of the two wings is 0.15mm. The bottom impermeable membrane is PLA / PHA membrane with a thickness of 25 μm.

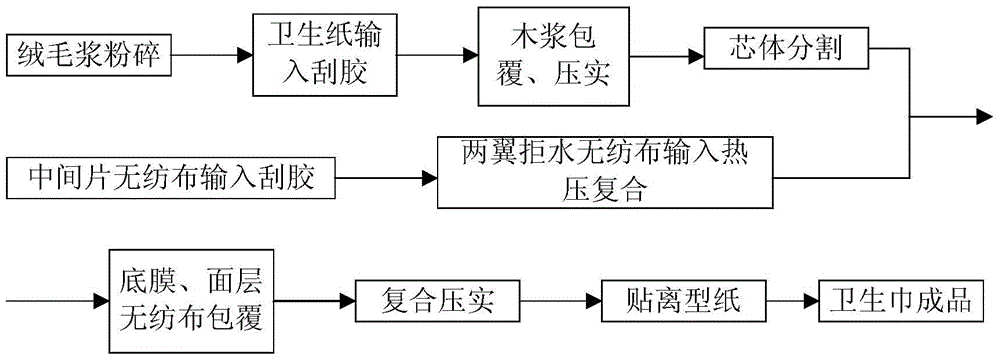

[0045] The sanitary napkin preparation p...

Embodiment 2

[0053] 1) Preparation of polylactic acid surface layer non-woven fabric:

[0054] Use PLA anti-seepage bottom film, the weight is 40g / m 2 , thickness 45μm; use 100% polylactic acid fiber with a length of 51mm and a fineness of 13.3dtex to make a surface non-woven fabric through antistatic pretreatment, opening, mixing, carding and hot-melt reinforcement, of which: first Spray 4% antistatic agent to control the moisture regain of the fiber to 8%; secondly, when carding the fiber, pay attention to controlling the carding speed of the roller carding machine to reduce the damage to the polylactic acid fiber, and adjust the cylinder speed to 1100 m / min , the speed of the working roll is 70 m / min, the speed of the upper stripping roll is 30 m / min, the speed of the lower stripping roll is 40 m / min, the speed of the upper condensing roll is 58 m / min, and the speed of the lower condensing roll is 45 m / min. The upper doffer speed is 72 m / min, the lower doffer speed is 70 m / min, and the...

Embodiment 3

[0060] 1) Preparation of polylactic acid surface layer non-woven fabric:

[0061] Use PLA / PBS anti-seepage bottom film, the weight is 30g / m 2 , thickness 35μm; use PLA / PHBV fiber length 51mm, polylactic acid fiber with a fineness of 2.2dtex, through antistatic pretreatment, opening, mixing, carding and hot-melt reinforcement to make surface non-woven fabric, wherein: first spray 4% antistatic agent, control the moisture regain of the fiber to 6%; secondly, when carding the fiber, pay attention to controlling the carding speed of the roller carding machine to reduce the damage to the polylactic acid fiber, adjust the cylinder speed to 1150 m / min, The working roll speed is 75 m / min, the upper stripping roll speed is 35 m / min, the lower stripping roll speed is 42 m / min, the upper condensing roll speed is 63 m / min, the lower condensing roll speed is 52 m / min, the upper The doffer speed is 78 m / min, the lower doffer speed is 79 m / min, and the production speed is 55 m / min; the two-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com