Multi-junction solar cell and manufacturing method thereof

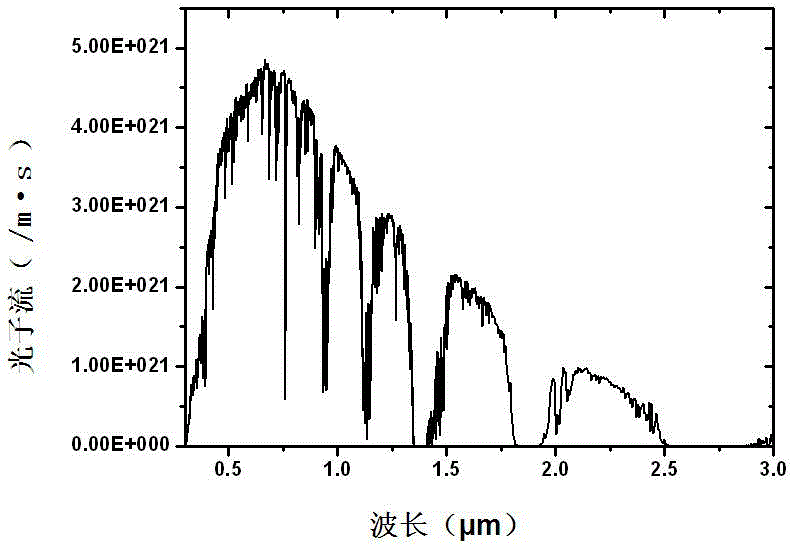

A technology of solar cells and batteries, which is applied in circuits, photovoltaic power generation, electrical components, etc., and can solve the problems of low photoelectric conversion efficiency of components and large differences in current density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

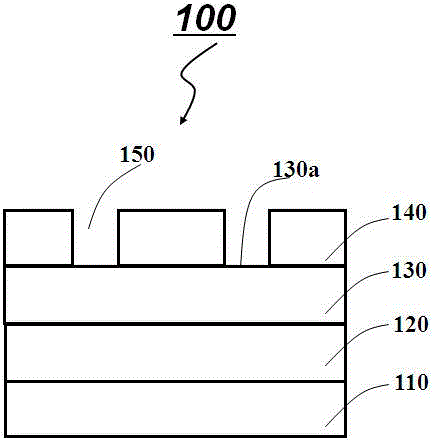

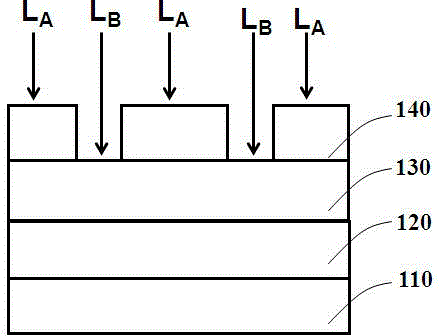

[0020] The multi-junction solar cell of the present invention reduces the light-receiving area of the top sub-cell, reduces the current of the top sub-cell, and leaves the remaining light for the sub-cell below to absorb, increases the current of the bottom sub-cell, and finally reaches the multi-junction cell. Current matching, which is applicable to any multi-junction cells, such as GaInP / GaAs double-junction cells, GaInP / GaAs / Ge lattice matching triple-junction cells, GaInP / InGaAs / InGaAs triple-junction cells, AlGaInP / InGaAsP / InGaAs / Ge quadruple-junction cells Cells, GaInP / InGaAs / InGaAs / InGaAs four-junction cells, GaInP / InGaAs / InGaNAsSb / Ge four-junction cells, AlGaInP / AlGaAs / GaAs / InGaNAs / Ge five-junction cells, etc. In general, the current limiting value of the sub-cell under the multi-junction solar cell is 5%~20%, so the light-receiving area of the top cell can be limited to 70%~97% of the total area. The implementation of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com