Method for determining content of formaldehyde in glycolonitrile product

A technology of hydroxyacetonitrile and determination method, applied in the direction of electrochemical variables of materials, etc., can solve the problems of long time, long time and high analysis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

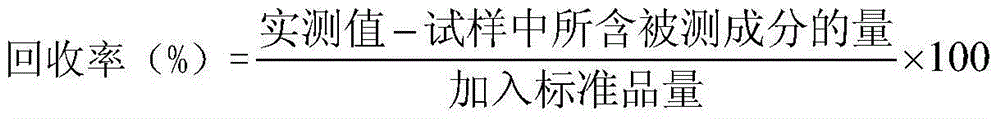

[0020] Example 1 Accuracy Verification - Standard Addition Recovery Experiment

[0021] A method for measuring the content of formaldehyde in a hydroxyacetonitrile product, which is specifically carried out according to the following steps: take a sample of a hydroxyacetonitrile product with a known formaldehyde content of 0.426%, weigh to an accuracy of 0.0002g, weigh 6 parts in total, and place them in 6 parts respectively. In two 100mL volumetric flasks, accurately add 0.4mL of formaldehyde standard solution with a concentration of 22.3022mg / mL into two of them, respectively, and precisely add 0.8mL of this formaldehyde standard solution into the other two volumetric flasks, and in the remaining Accurately add 1.2mL of the standard formaldehyde solution to the two volumetric flasks, add water to the mark, and shake well. Accurately draw 25mL in 6 volumetric flasks, place each in 6 250mL beakers, add 50mL of water respectively, place them on a magnetic stirrer in turn, inser...

Embodiment 2

[0052] Embodiment 2 repeatability experiment

[0053] A method for measuring formaldehyde content in hydroxyacetonitrile products, which specifically weighs about 5g of the same batch of hydroxyacetonitrile product samples, weighs to an accuracy of 0.0002g, dilutes with water to 100mL, shakes well, and uses it as the experimental solution; precision absorption experiment Put 25mL of the solution in a 250mL beaker, absorb 5 parts in total, add 50mL of water respectively, place them on a magnetic stirrer in turn, insert a pH meter electrode with an accuracy of 0.01pH, start stirring, and use 0.1mol / L sodium hydroxide solution and 0.1 mol / L sulfuric acid solution adjusted to pH=7, quickly add 25mL of sodium sulfite solution with pH=9.2 and concentration of 126g / L, immediately use The sulfuric acid standard titration solution is titrated to a pH of 9.18 as the end point; the determination process is completed within 3 minutes from the adjustment of the pH value of the experimen...

Embodiment 3

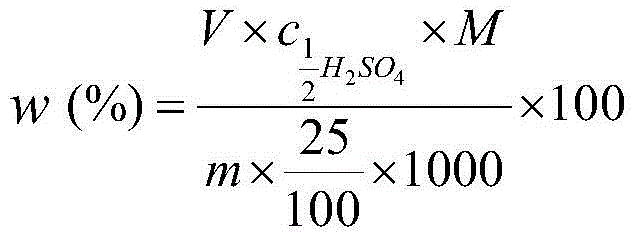

[0058] A method for measuring the content of formaldehyde in hydroxyacetonitrile products, which specifically weighs 5.1062g of hydroxyacetonitrile product samples, weighs to an accuracy of 0.0002g, dilutes with water to 100mL, shakes well, and uses it as the test solution; accurately absorbs 25mL of the test solution In a 250mL beaker, add 50mL of water, place it on a magnetic stirrer, insert a pH meter electrode with an accuracy of 0.01pH, start stirring, and adjust the pH with 0.1mol / L sodium hydroxide solution and 0.1mol / L sulfuric acid solution =7, quickly add 25mL of sodium sulfite solution with pH=9.2 and concentration of 126g / L, and immediately use The sulfuric acid standard titration solution is titrated to a pH of 9.18 as the end point; the determination process is completed within 3 minutes from the pH value of the experimental solution, and the operating temperature is controlled at 25°C; The formaldehyde content is 0.90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com