Detection and Repair Method of Reinforced Concrete Structure of Coastal Buildings

A technology of reinforced concrete and repair method, applied in building construction, building maintenance, construction, etc., can solve problems such as the inability to meet the requirements of building structure safety and use function, and the technical lag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

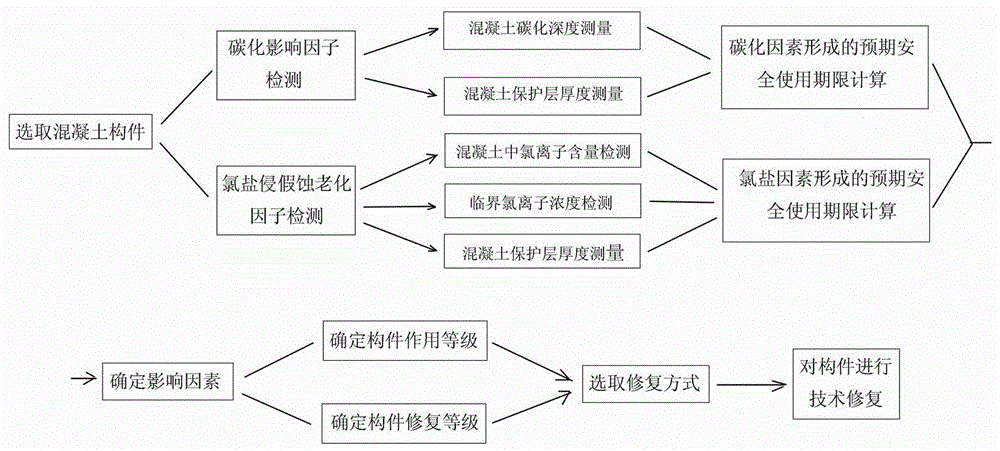

Method used

Image

Examples

Embodiment 1

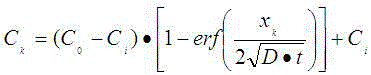

[0045] In 2008, a multi-storey residential building in Guangao, Shantou City was inspected, and the carbonation depth of 20 columns on the first and second floors was randomly checked. The measured carbonization depth has a minimum value of 5.5 mm, a maximum value of 20.0 mm, an average value of 10.5 mm, and a standard deviation of 3.60. The carbonization depth with a 95% guarantee rate is 16.4 mm. Measure the thickness of the protective layer of the above column, the minimum value is 18.5mm, the maximum value is 38mm, the average value is 27.7mm, and the standard deviation is 3.44. The thickness of the protective layer with a 95% guarantee rate is 22 mm. The actual age of the structure is 19 years. According to the formula, , then the expected safe service life , the remaining safe use period is 34.2-19=15.2 years.

[0046] The chloride ion content of about 15 columns was randomly checked, and the powder was drilled at a depth of 5-10mm, 10-15mm, 15-20mm, 20-25mm, 25-30m...

Embodiment 2

[0050] In a hotel, the bottom column was tested in 2007, and the carbonization depth with a 95% guarantee rate was 9.2 mm, and the thickness of the protective layer was 24 mm. The actual age of the structure is 25.5 years. , the life expectancy , and the remaining safe use period is greater than 50 years.

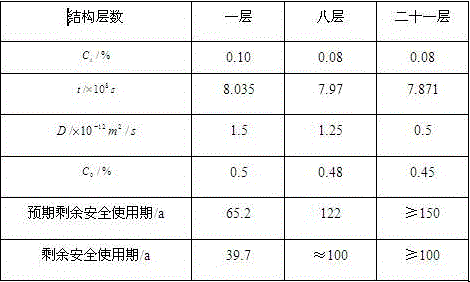

[0051] The first, eighth, and twenty-story columns were respectively tested for chloride ion content in concrete. The average thickness of the protective layer was 25mm, and the critical concentration of chloride ion was taken as 0.4% (accounting for cement consumption). The calculation results are shown in the table below.

[0052]

[0053] Based on the above results, the remaining safe service life of the building based on durability is 39.7 years.

[0054] It can be seen that the influencing factor of the remaining safe service life of the building is chlorine salt erosion. The building is located in a coastal urban area more than 300 meters away from the coastli...

Embodiment 3

[0059] The teaching building of a private school had a structural age of 16 years in 2009, and some structural columns and floor members had peeling off of the concrete protective layer and corrosion of steel bars.

[0060] The carbonation depth of 30 concrete columns was sampled. The measured carbonation depth was 7.5 mm minimum, 23.5 mm maximum, 12.5 mm average, and 3.75 standard deviation. The carbonation depth with a 95% guarantee rate was 18.7 mm. Measure the thickness of the protective layer of the above column, the minimum value is 15.5mm, the maximum value is 36.5mm, the average value is 29.5mm, the standard deviation is 3.55, and the protective layer thickness with 95% guarantee rate is 23.7 mm. According to the formula, , then the expected safe service life , the remaining safe use period is 39.8-16=23.8 years. Extract 20 concrete pillars and measure the chloride ion content of each depth layer, through using the calculation method of the present invention, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com